Out-of-limit actions tab, Table 10.1 – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 83

Configuration

Chapter 10. Production Monitoring

IM8002

Power Wave® Manager User Manual

10.5

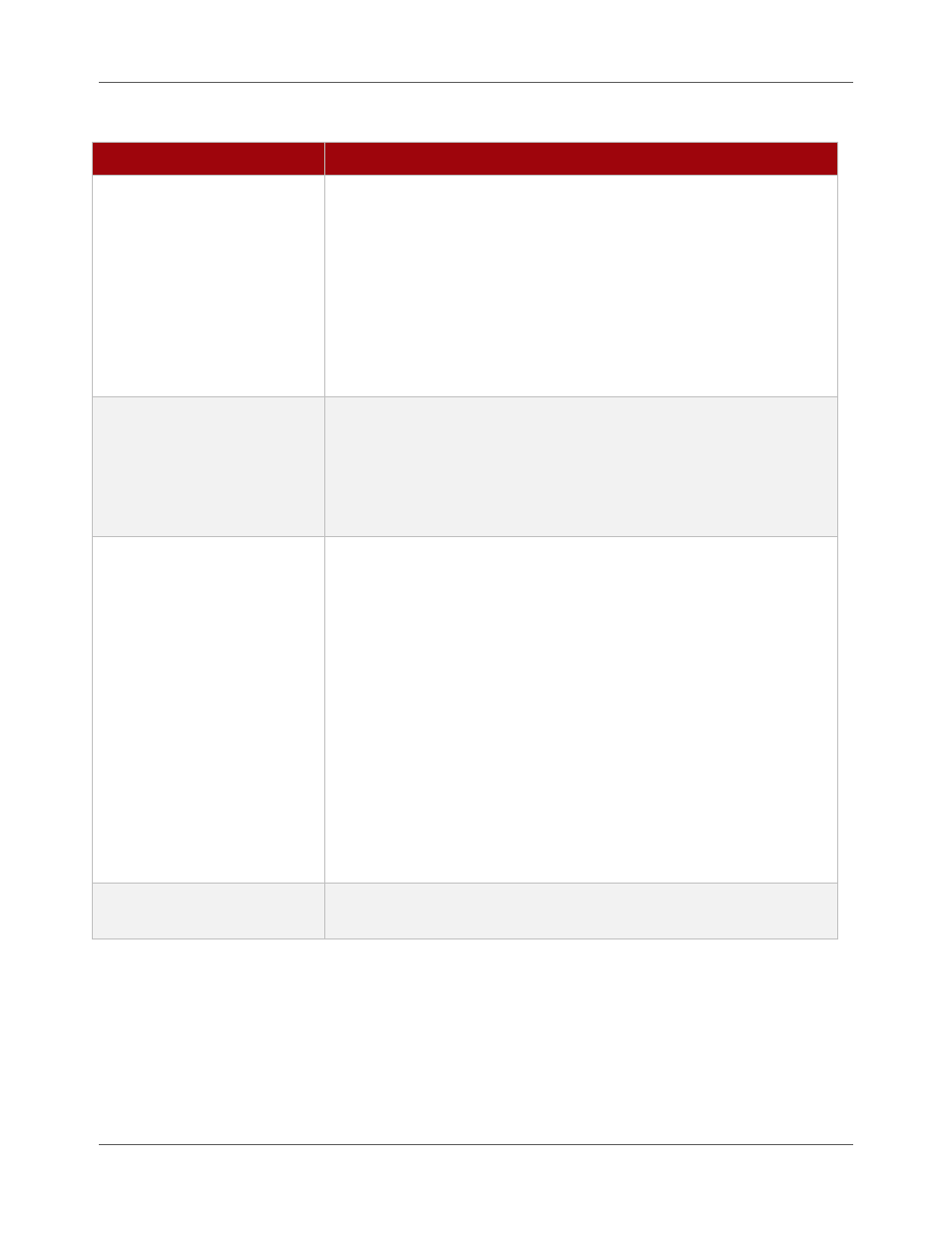

Table 10.1 Options on the Weld Profile Selection Tab

Field

Description

Select Weld Profile

automatically based on the

last digit of the Workpoint

When you choose this option, the last digit of the welding set point

becomes the Weld Profile number currently in use.

For example, if the welding set point is set to 125, the Power Wave®

will use Weld Profile 5 for the given weld. If the last digit of welding

set point is zero (0), the Power Wave® will use Weld Profile 10.

With this method, the user can access only 10 of the available Weld

Profiles in Power Wave® Manager, constricting procedure

adjustments. Despite these limitations, this method is simple and

effective, and may be the preferred choice for many applications.

Allow an external controller to

select the Weld Profile

When you choose this option for selecting the Weld Profile, you tell

the Welding Power Source to provide an external controller (e.g.,

DeviceNet controller such a PLC or an ArcLink® controller FANUC®

RJ3iB v6.4) with direct access to all Weld Profile numbers on the power

source. The controller must be one that communicates to the power

source over a DeviceNet or ArcLink® network.

Select Weld Profile based on

User Interface memory

selection

When you choose this option, you have configured the Welding Power

Source to use the memory buttons on the connected User Interface to

select the Weld Profile.

This method offers ease of use and straightforwardness in selecting

the Weld Profile, but the number of Weld Profiles that can be selected

are limited by the number of physical buttons on the User Interface.

For example, if there are only six memory buttons on the User

Interface, the Weld Operator can only choose from six Weld Profiles.

With this configuration chosen, if the Weld Operator does not choose

a memory button before performing the weld, the power source uses

the last Weld Profile by default. On second-generation Welding Power

Sources and third-generation power sources that have not upgraded,

this means Profile 32. On third-generation Welding Power Sources

that support this feature, this means Profile 200. See page 10.3 for

more details on Weld Profiles.

Select Weld Profile based on

Analog Interface I/O

When you select this option, the I/O from the analog interface is

configured to choose the Weld Profile.

Out-of-Limit Actions Tab

On the Out-of-limit actions tab, you tell this Welding Power Source what action to take when a weld

exceeds limits established on the Profile limits tab (page 10.7). You can also provide the Welding Power

Source with a short amount of tolerance time before it takes that action. The Out-of-limits tolerance fields

represent the total accumulative amount of time the weld can be outside the limit before the selected

action occurs.