Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 48

Chapter 7. Network Settings

DeviceNet

7.6

Power Wave® Manager User Manual

IM8002

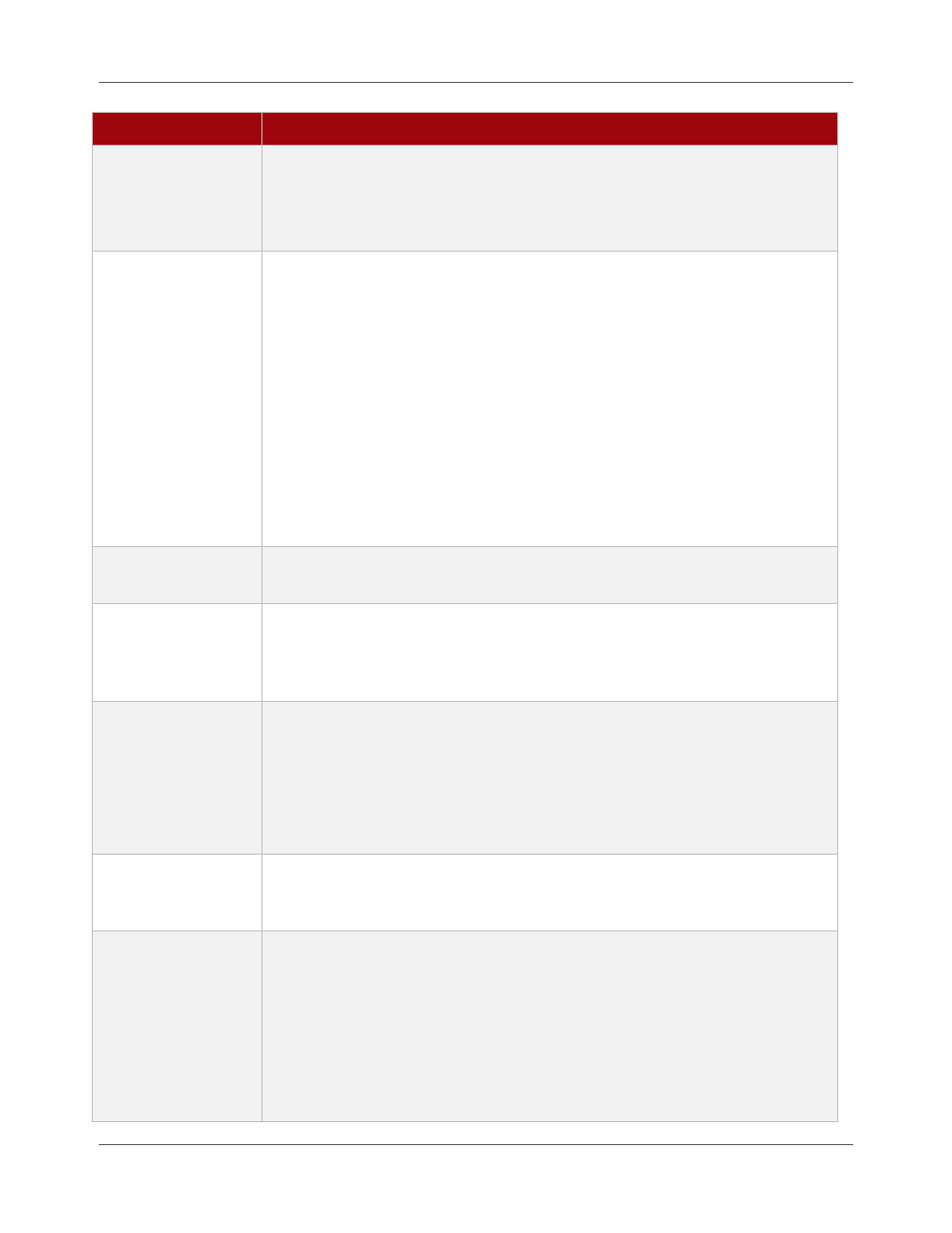

Field

Description

Power Wave® Manager to set the MAC ID of the DeviceNet interface.

STOP |

If you change the MAC ID, you must cycle the power to the Welding

Power Source (off then back on) in order for the change to take effect. Be

careful not to cycle the power while the power source is currently welding.

Baud Rate

This field displays the current baud rate configured in the DeviceNet interface

installed on this Welding Power Source.

For the following power sources, the Baud Rate is usually set by a DIP switch

located on the gateway board, but you can also set the baud rate from Power

Wave® Manager: PW455, PW455M, ACDC1000, PW655, and Welding Power

Sources that use the K2436-1 Ethernet/DeviceNet Communication Interface.

For other Welding Power Sources that do not have a DIP Switch, you must use

Power Wave® Manager to set the Baud Rate of the DeviceNet interface.

STOP |

If you change the Baud Rate, you must cycle the power to the

Welding Power Source (off then back on) in order for the change to take

effect. Be careful not to cycle the power while the power source is currently

welding.

Event Logging

The Event Logging checkboxes allow you to control the types of issues that

create a log entry when they occur on this DeviceNet module.

Enable passive mode

operation

Place a check mark in this checkbox when you need to use the DeviceNet

connection only to monitor system operation. When you enable passive mode,

the polled inputs from DeviceNet have no effect on the system except for the

Weld Output disable bit and the Production Monitoring Fault Reset bit.

Restore settings from

memory on reset

DeviceNet will automatically restore weld schedule values on power up that are

not accessible from a polled connection. These include weld mode, strike,

restrike, cold-inch wire feed speeds, and times for preflow, postflow and

burnback.

NOTE |

If the system contains a user interface with a memory panel or a

robot/PLC that restores settings on power up, do not check this box.

Fault if no polled

connection detected

This option disables welding if a polled DeviceNet connection is not present.

Place a check mark in this checkbox when a DeviceNet master controls the

machine.

Report Trim/Wave

Outer Process Limits

When you choose to report the Trim/Wave Control input in Engineering units

and these inputs are dependent on the Workpoint, place a check mark in this

checkbox to report back the high and low limits of the Trim and Wave Control

parameters. Typically, this item is checked.

If there is no check mark in this checkbox, the returned limits will be based on

the Workpoint. As the Workpoint changes, the acceptable range for the Trim

and Wave Control change as well, removing the check mark from this box also

reports back that acceptable range.