Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 108

Appendix B. FANUC Robots

FANUC® Robot Application (Prior to v7.70P/21)

B.2

Power Wave® Manager User Manual

IM8002

Requirements

When you want to implement Production Monitoring™/CheckPoint™ for the FANUC robot, you need to

make sure you have met the following requirements:

ArcTool® Software

The robot must have ArcTool® software version 6.40-1M or later installed. This version includes

two programs, WR_AL_AT.VR and RD_AL_AT.VR that form the basis of Production

Monitoring™/CheckPoint™ robotic interface. These two program names are seen in the Select

Menu program listing along with the all other programs in the robot’s memory.

KAREL Software

The KAREL software function must be enabled. KAREL is a FANUC software tool that performs

functions behind the scenes, out of view, during normal robot operations.

To check to see if it is enabled:

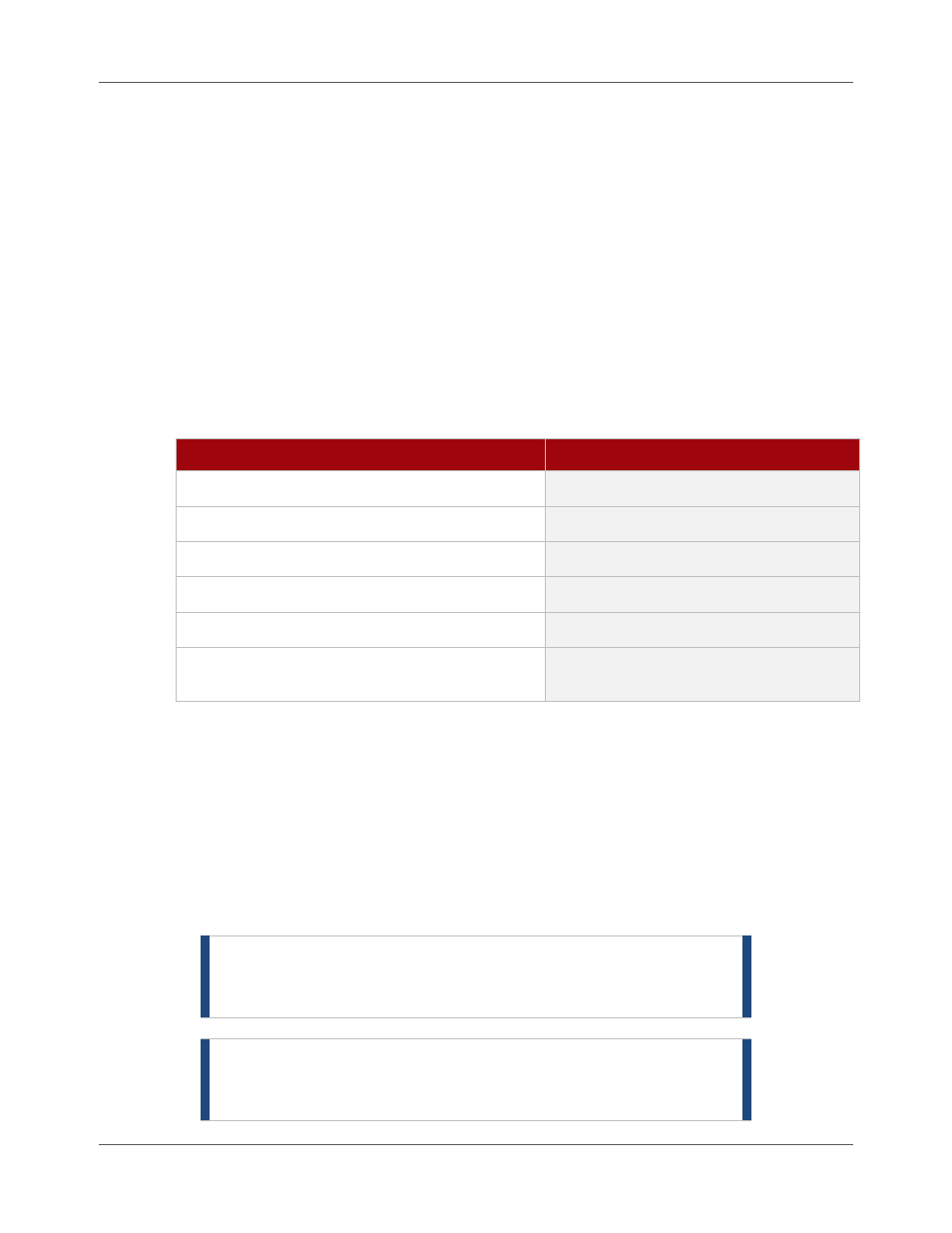

Procedure

Details

1.

Press the Menu key.

2.

Cursor to line 0-next and press Enter.

3.

Cursor to line System and press Enter.

4.

Press F1-Type key.

5.

Cursor to line Variables and press Enter.

6.

Cursor down to line $KAREL_ENB and set the

value to 1 if it isn’t already and press Enter.

Registers

Nine registers need to be set aside and dedicated for Production Monitoring™/CheckPoint™ use.

By default, the robot has 200 registers available for use to perform math functions. (This can be

increased to 500 if needed.) This manual will use registers 1 through 9 for examples.

Ethernet Module

The Welding Power Source must have the Ethernet module installed, set up and running on a

network. A network connection can also be established to the Welding Power Source through

the robot, providing it has been set up, configured, and is running on a network. Refer to

FANUC® documentation for more information.

NOTE |

Production Monitoring™/CheckPoint™ e-mail functionality

is only available when the Welding Power Source is directly

connected to the network.

NOTE |

If the robot is an E-model, an E-Cell for example, the

network connection must be directly to the Welding Power

Source external Ethernet module.