Polled i/o connection – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 49

DeviceNet

Chapter 7. Network Settings

IM8002

Power Wave® Manager User Manual

7.7

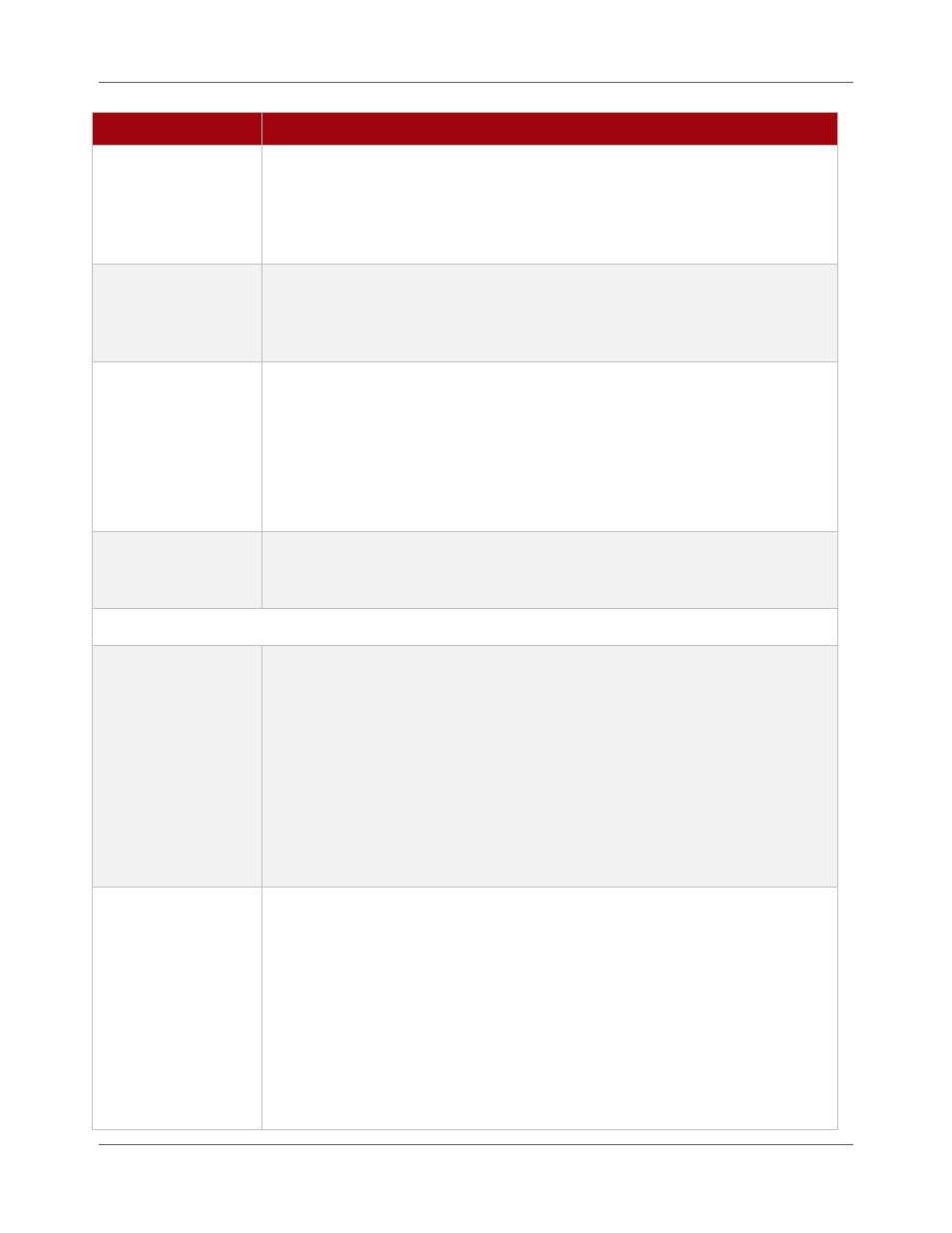

Field

Description

TAST update

frequency

This parameter is used for Through the Arc Seam Tracking (TAST). The lower

the number the more often the feedback is updated, but higher the system load

on the boards. In general, if TAST is being used, this frequency is set to a value

between 10 and 20. Otherwise, a value of 100 is usually acceptable. This value

is only relevant for the PW455, 455M, 655, 355, and ACDC1000.

Meter time constant

This parameter sets the filtering of the feedback data. The default value of 400

is usually used unless TAST is being done. With TAST, this field is usually set to a

value around 75. This value is only relevant for the PW455, 455M, 655, 355,

and ACDC1000.

Analog scans

between updates

This determines how often the analog input channels (i.e., workpoint, trim, and

wave control) update the system in terms of polled I/O scans. For example, if

you enter 50, every 50th I/O scan will be accepted.

The setting of this item depends on how often the Welding Power Source is

scanned. For systems with a scan rate of 200 or more, the default is generally

50. For systems with very low scan rates, such as 10 Hz, a setting as low as 2

might be needed.

Cold-inch wire feed

speed

This parameter sets the feed speed of the wire while cold-inching or jogging the

wire. This value is used for either cold-inching forward (Jog +) or cold-inching

reverse (Jog -). This value is in units of inches per minute (IPM).

Polled I/O Connection

Workpoint input

This indicates whether the values passed to the system through the analog

DeviceNet channels for the Workpoint parameter are raw values or scaled

engineering values. For most applications, choose Engineering units.

For example, when the Workpoint is in inches per minute and you choose

Engineering units, a value between 50 and 800 might be expected to be

commanded on the DeviceNet analog input for the Workpoint. This would

represent a value of 50 to 800 inches per minute.

When you choose the Unscaled values option, the commands for Workpoint

range from 0 to 32767, corresponding to the minimum and maximum

Workpoint of the selected Weld Mode.

Trim/Wave

Control input

This indicates whether the values passed to the system through the analog

DeviceNet channels for the Trim and Wave Control parameters are raw values

or scaled engineering values.

For example, when the Trim is in volts and you choose Engineering units, a value

between 75 and 520 might be expected to be commanded on the DeviceNet

analog input for the Trim. This would represent a value of 7.5 to 52.0 volts.

When you choose the Unscaled values option, the commands for Trim and

Wave Control range from -32768 to 32767 with 0 representing a nominal value.

A great majority of applications will require Trim and Wave Control command

values to be set near the nominal value.