Weld cable test tab – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 38

Chapter 6. Power Source Settings

Cable Settings and Tests

6.4

Power Wave® Manager User Manual

IM8002

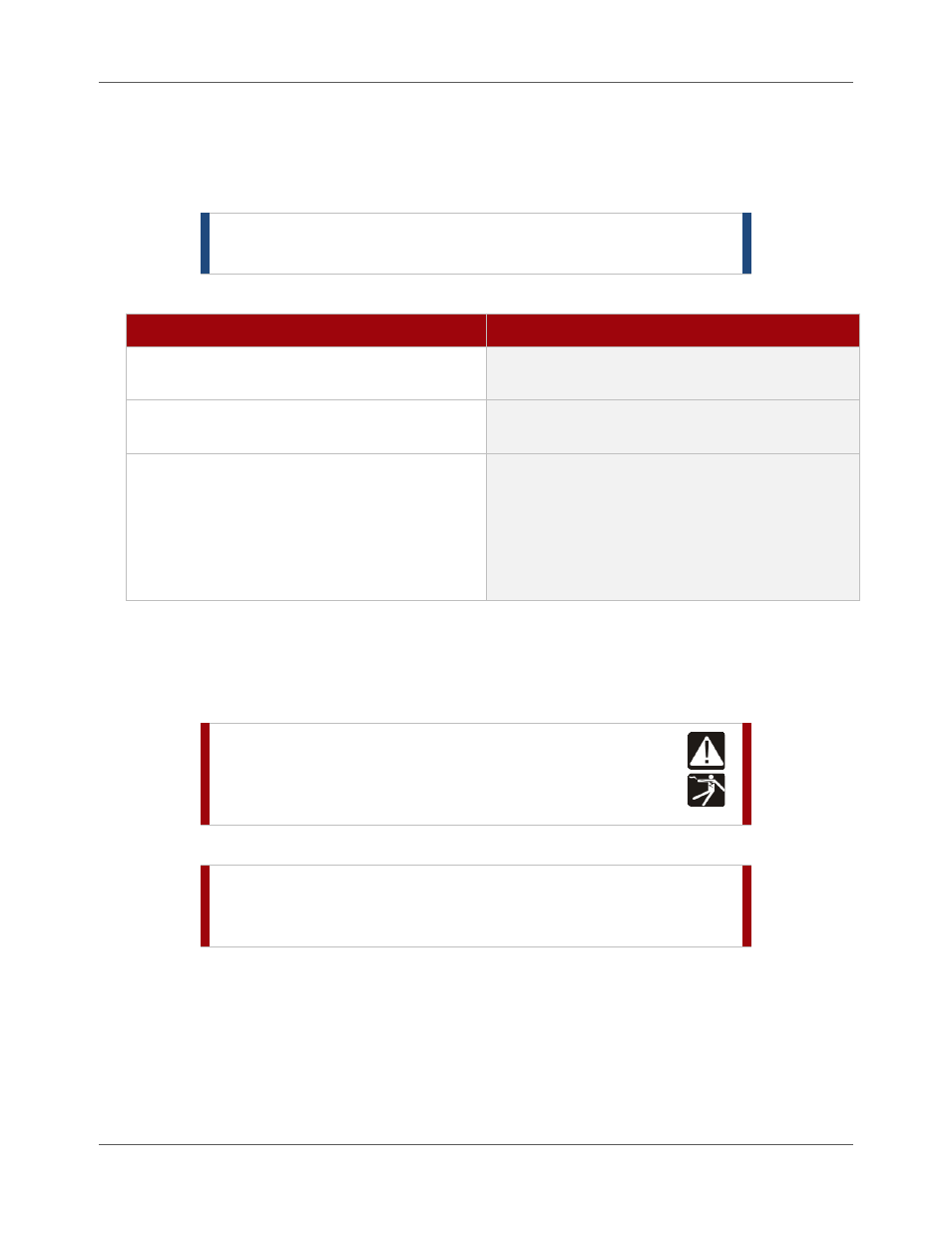

Enable Negative Welding Polarity

If negative welding polarity is required for the Welding Power Source, such as in some Innershield™

applications, you may need to configure the correct voltage sense location manually.

NOTE |

If the system is already configured to sense arc voltage at

the remote voltage sense leads, no changes are required.

To enable negative welding polarity:

Procedure

Details

1.

Remove the check mark from the Automatic

hardware sense lead selection checkbox.

2.

Place a check mark in the Force negative

weld polarity checkbox.

3.

Click the Apply settings button

NOTE |

If the sense lead selection is specified

for a welding procedure, that selection will have

precedence over the settings you set here.

Therefore, some welding processes, such as TIG

(GTAW), stick (MMAW), and SMAW, will override

the Power Wave® Manager settings.

Weld Cable Test Tab

The Weld cable test tab (Figure 6.3) allows you to measure the resistance and the inductance of your

welding circuit. This can be used to determine how setup changes affect the welding circuit. In order to

run this test, the contact tip must be shorted to the work piece.

STOP |

Do not trigger the power source during this test.

The power source will be triggered for a short

time. Please verify output is turned off, and

short contact tip to work before proceeding.

Click the Perform test button to begin the inductance and resistance test.

STOP |

When you perform this test, the Welding Power Source’s

output will be turned on for a very short time (100

milliseconds).

Once the test is complete, Power Wave® Manager displays the values that were calculated based on the

downloaded weld trace. The resistance value appears in the Resistance field (measured in milliohms) and

the inductance value appears in the Inductance field (measured in microhenries) (Figure 6.3).