User interface, Multiple user interfaces – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 62

Chapter 8. Wire Feeder

User Interface

8.4

Power Wave® Manager User Manual

IM8002

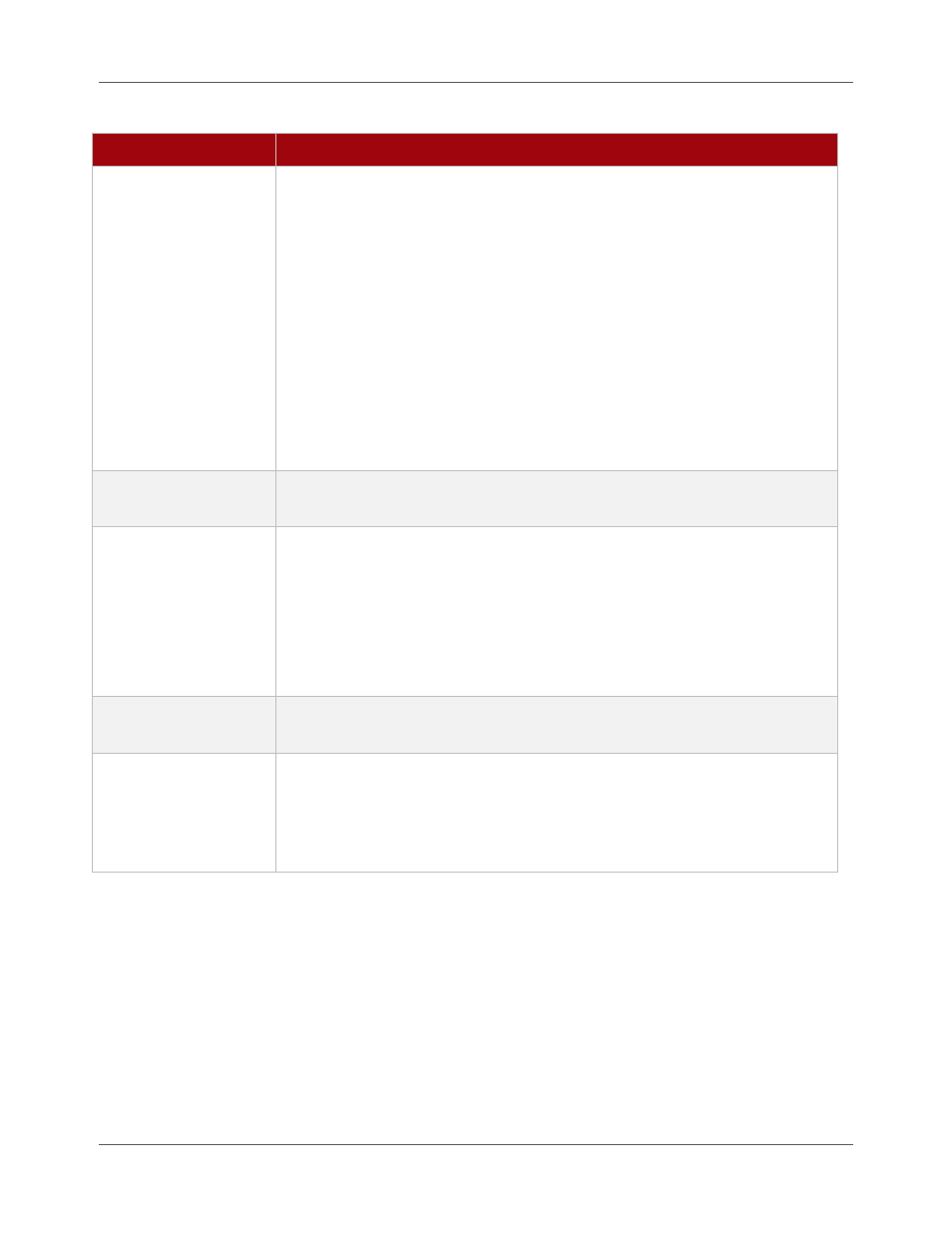

Table 8.2

Fields on the Diagnostics Tab

Option

Description

WFS feedback

The fields in the WFS feedback section displays the wire feed speed

information coming from the wire feeder. This includes:

Set WFS: This is the wire feed speed that was set in the Weld Profile

being used for the weld or that was set manually on the machine by

the Weld Operator.

Actual WFS: This field displays the actual speed at which the feeder

feeds the wire into the weld.

Maximum WFS: This field displays the uppermost limit to the wire

feeder’s speed capability. This is the highest speed at which the wire

feeder can make a successful weld.

Minimum WFS: This field displays the lowest limit to the wire feeder’s

speed capability. This is the slowest speed at which the wire feeder

can make a successful weld.

Status

These indicators display the current status of the wire feeder to which you

are connected.

Cold-inch Wire

In the Cold-inch Wire section, you can use the Inch forward and Inch reverse

buttons to feed the wire through the feeder without welding. The Inching

and I/O status indicator lights let you know that the machine is in use and the

input/output communication status.

The Cold-inch speed (ipm) field allows you to set the speed at which the

machine feeds when you click the inching buttons. This defaults from the

current speed on the wire feeder.

Power feedback

The fields in the Power feedback section provide you with the power details

for the wire feeder so you can keep your eyes on the power as you diagnose.

Miscellaneous

In the Miscellaneous section, the Gas purge or Flux fill button (depending on

your system) allows you to prepare the wire feeder. The Solenoid indicator

lets you know when the feeder is active when using the button. The Sense

lead polarity field displays the polarity for the machine to which you are

connected.

User Interface

If the Welding Power Source to which you have connected has a user interface module attached, the User

interface section of Power Wave® Manager provides you the ability to configure that module, including

integration of specific welding process configurations (i.e., sequences, schedules, procedures, profiles, and

modes).

Multiple User Interfaces

If there are more than one User Interface connected to this Welding Power Source, the User Interface

section provides a drop-down at the top of the window so you can select which User Interface to configure.