Profile limits tab – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 85

Configuration

Chapter 10. Production Monitoring

IM8002

Power Wave® Manager User Manual

10.7

TIP

|

If the Action on WeldScore limit value field is grayed out,

either the power source does not support WeldScore™ or

the power source has older firmware that needs to be

updated. See page 3.1 for details on upgrading the power

source’s firmware.

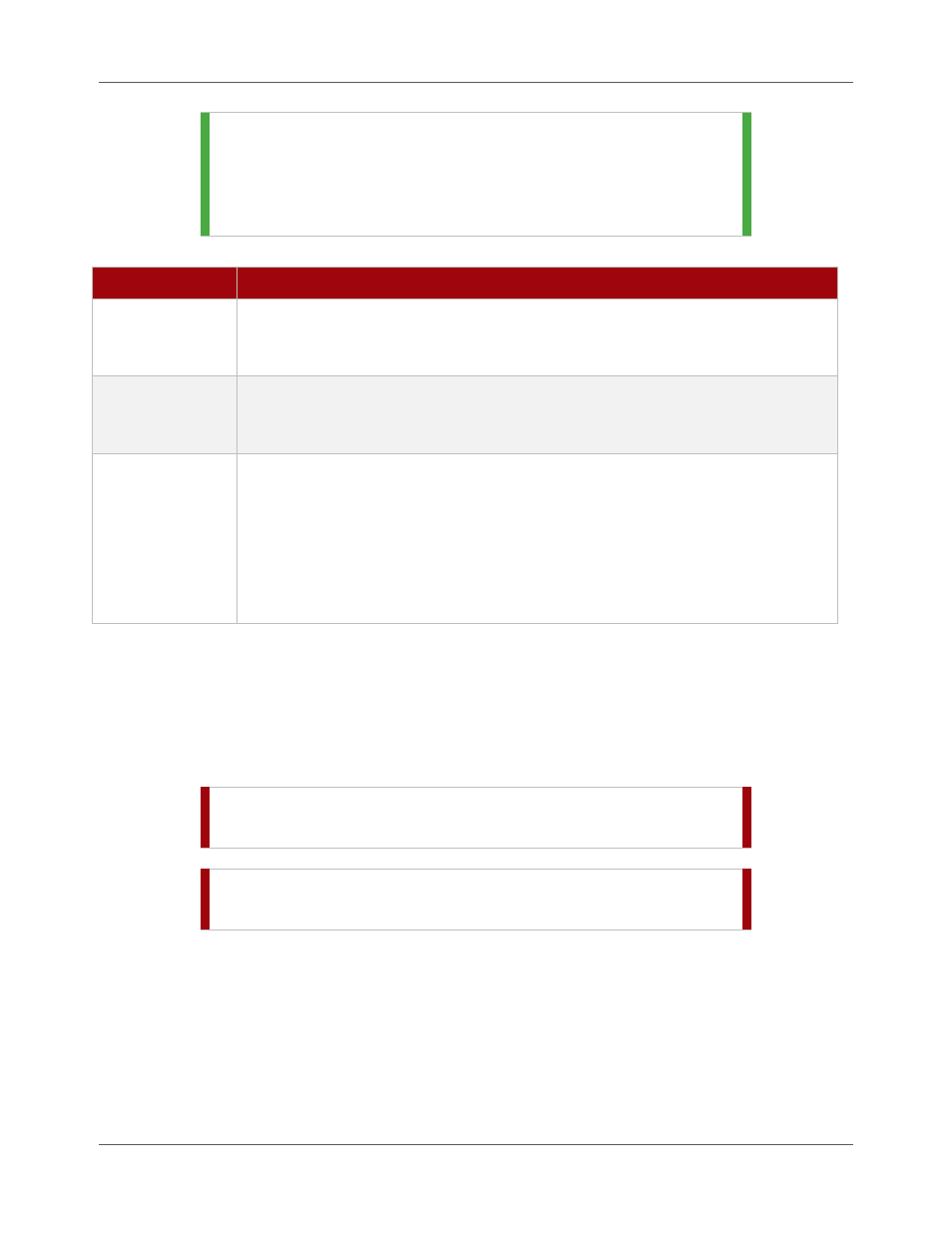

Table 10.2 Available Actions When a Weld is Out of Limits

Field

Description

Log Event

This option tells the Welding Power Source to create an event log entry to record

that the weld was out of limits. The power source continues welding, even if the

weld does not meet limits set on the Weld Profile.

Fault System

If you select this option, the power source will stop the weld currently in progress

when it detects the weld has gone outside the limits set by the Weld Profile. The

Weld Operator can make adjustments and begin welding again.

Alarm Latch

When you select this option, a weld that goes outside the limits set by the Weld

Profile causes the power source to enter into a faulted state when the weld ends

(also known as a “latched fault”). In order for the power source to continue

welding, the Weld Operator must clear the fault.

You can reset an Alarm Latch fault on the Diagnostic tab under Production

Monitoring > Register (page 10.3), or by cycling the power to the Welding Power

Source (off then back on).

Profile Limits Tab

The Profile limits tab is where you set limits or adjust trained limits for every Weld Profile available to the

Welding Power Source. Each power source stores all Weld Profiles that are available, but it can only access

the profiles based on the choice you make on the Weld Profile selection tab (page 10.4). You can set the

profile limits manually on the Profile limits tab or you can teach the power source what you consider to be

a weld within limits.

STOP |

Be sure you plan your Weld Profiles before you begin. See

page 11.1 for more details.

STOP |

For information on training a weld for a Weld Profile, please

refer to Chapter 11.