Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 118

Appendix B. FANUC Robots

Procedure: Enabling Arc Production Monitor

B.12

Power Wave® Manager User Manual

IM8002

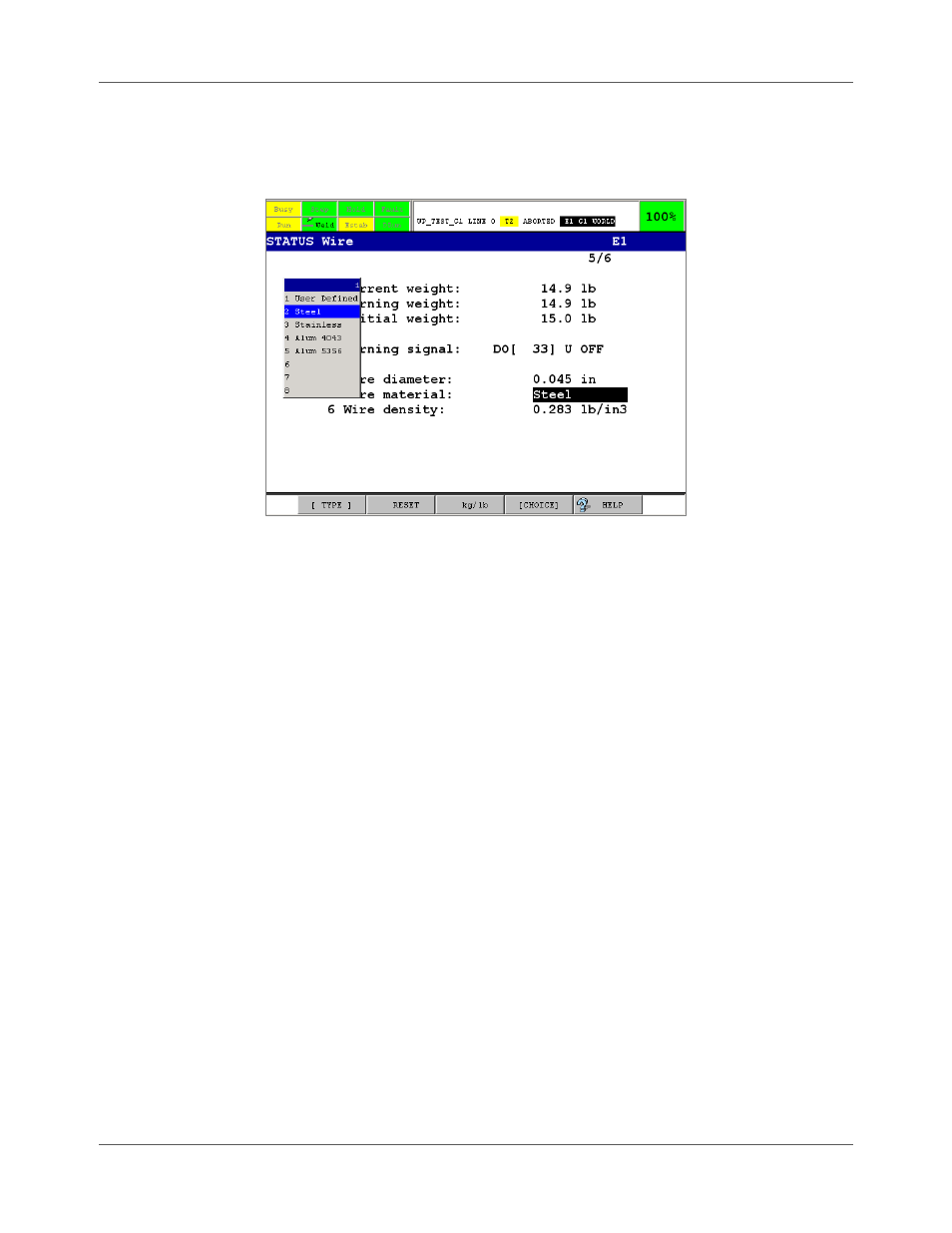

At the top of the Wire menu, the Current weight of the wire supply is displayed. Each of the settings for

this menu can be changed by moving the cursor to the respective line and entering the desired value. The

Wire Material entry on line 5 allows you to select from the F4 (CHOICE) key as shown in Figure 11.4.

Figure 11.4 Changing a Setting

The wire density is automatically entered for the listed materials and you can specify a different value by

choosing the User Defined material choice.

When the Warning weight is reached, the Digital Output specified on the Warning signal line will turn on.

It can be reset by changing the Warning weight or by pressing F2, RESET to restore the initial weight value.

WeldScore™ Display

WeldScore™ can be displayed on the robot Teach Pendant when the Arc Analog Meter option (J599) is

installed on the robot controller. You can also create your own teach pendant menu that includes the

display of WeldScore™ by pointing the display control to the system variable

$AWELEPM[equip_num].

$I_WELDSCORE. (Refer to the FANUC iPendant Controls reference manual for details about creating your

own menus on the teach pendant.)

The Arc Analog Meter option allows you to display the weld current, voltage and wire feed speed as

graphical representations of an analog meter. The Arc Analog Meter display is selected by pressing the

STATUS key, followed by the F1 (TYPE) key and selecting the Anlg Meter option from the list. Select either

F2 (METER1) or F4 (METER2) to display a pop-up menu to choose WeldScore™ as a displayed variable.