Diagnostics tab, Configuration, Weld profiles – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 81

Configuration

Chapter 10. Production Monitoring

IM8002

Power Wave® Manager User Manual

10.3

Diagnostics Tab

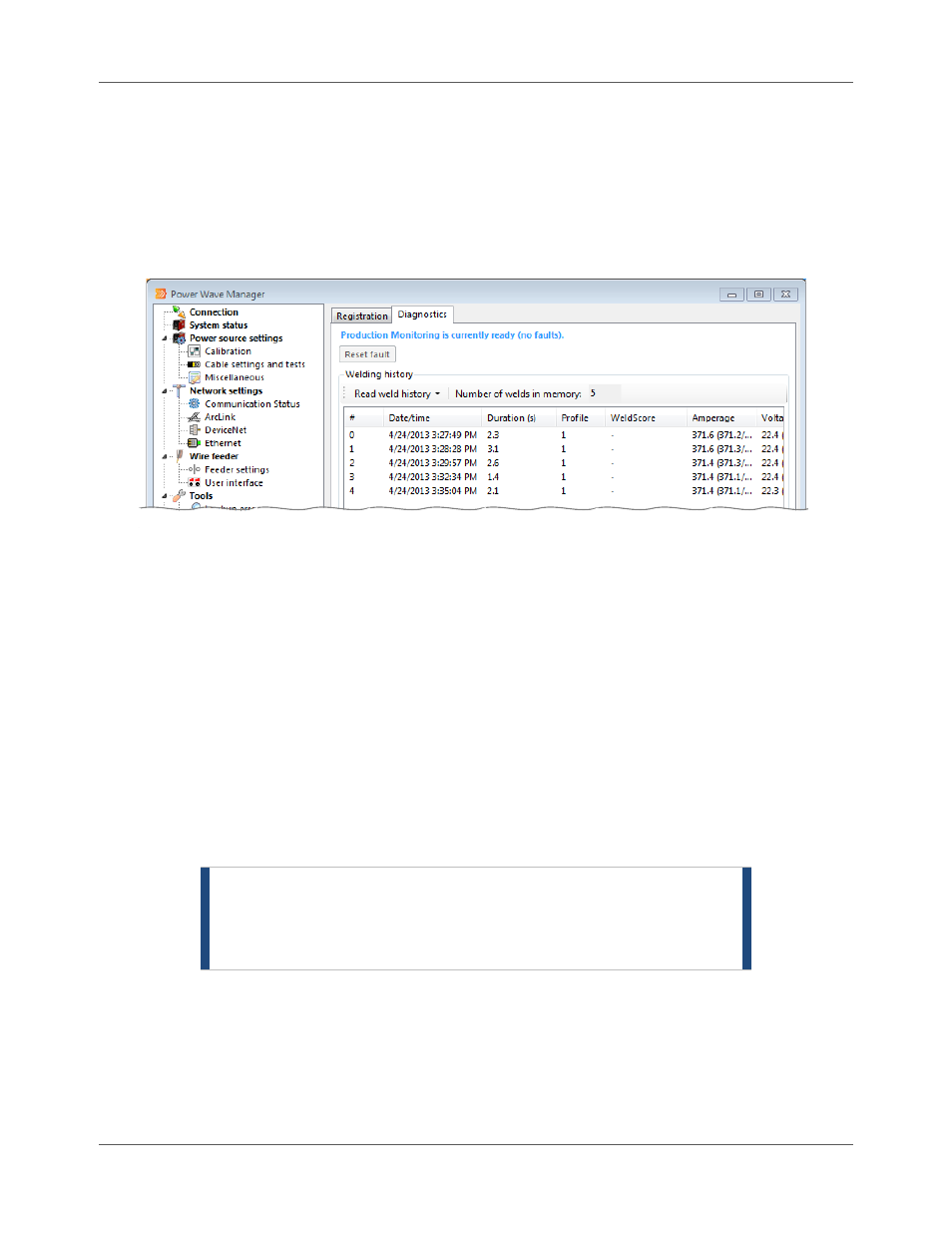

The Diagnostics tab provides you with a way to view a list of welds that the power source currently has in

its memory since the last time it powered on (the Number of welds in memory field), as well as a way to

reset the machine if there is an Alarm Latch detected from an out-of-limits condition (click the Reset fault

button). At the top of the tab, Power Wave® Manager displays the current status of the monitoring

software on the power source.

Figure 10.3 Diagnostics Tab

You can view the list of welds in a few different formats, depending on your Welding Power Source. From

the Read weld history drop-down menu, simply select the highest number format that works with your

Welding Power Source:

Format 1 displays basic information about each weld.

Format 2 includes more detailed information about each weld.

Format 3 includes the most information about each weld, including WeldScore™ and part serial

numbers.

Configuration

The Configuration section allows you to set up the Weld Profiles needed on this Welding Power Source,

set up e-mail notifications from the power source, manage the consumables used by the power source

and more.

NOTE |

When you finish changing configuration options on one

or more tabs, be sure to click the Apply settings button

to commit your changes. Otherwise, you will lose your

new settings.

Weld Profiles

One of the principal goals of Production Monitoring™ or CheckPoint™ is to report on welds that are outside

of user-defined limits with respect to WeldScore™, current, voltage, wire feed speed and duration. This

goal would be simple to implement if the Welding Power Source were to perform only one type of weld

over and over. However, in practical applications, this is not the case. The assembly of many different

industrial components requires welds of varying type and length.