Procedure: enabling arc production monitor – Lincoln Electric IM8002 POWER WAVE MANAGER User Manual

Page 114

Appendix B. FANUC Robots

FANUC® Robot Application (v7.70P/21 or Later)

B.8

Power Wave® Manager User Manual

IM8002

FANUC® Robot Application (v7.70P/21 or Later)

This section reviews FANUC support for Production Monitoring™/CheckPoint™ starting with the ArcTool

v7.70P/21 release or later. See page B.1 for information on supporting Production Monitoring™/

CheckPoint™ in a FANUC robot prior to the v7.70P/21 release. Refer to the FANUC ArcTool Setup and

Operations Manual for full details about configuring the software and using this feature with the FANUC

robot.

ArcTool v7.70P/21 and later provides enhanced support for Production Monitoring™/CheckPoint™. The

new features are available when either the Lincoln America Package R787 or the Arc Production Monitor

Package R788 software option is installed in the robot controller. There is an additional option entitled

“Arc Analog Meter” option J599 that provides a display of WeldScore™, current, voltage and wire feed

speed in real time on the teach pendant that may be used.

When the Lincoln America Package R787 is installed on the robot controller, the following functions are

provided through the teach pendant:

Weld Profile selection

Part serial number setting

Production Monitoring™ error handling

Proxy server support for weld data forwarding to the CheckPoint™ cloud server

Wire usage monitor setup

If the Arc Production Monitor Package R788 is installed, the full suite of Internet Connectivity and

Customization (R558) features and the Arc Analog Meter option J599 are installed as well.

Procedure: Enabling Arc Production Monitor

Conditions

The following conditions must be met:

The robot controller is configured with ArcTool V7.70P/21 or later, and the option list includes

either the Lincoln America Package R787 or the Arc Production Monitor Package R788 option.

The controller is powered on and running at Cold Start (normal operating condition).

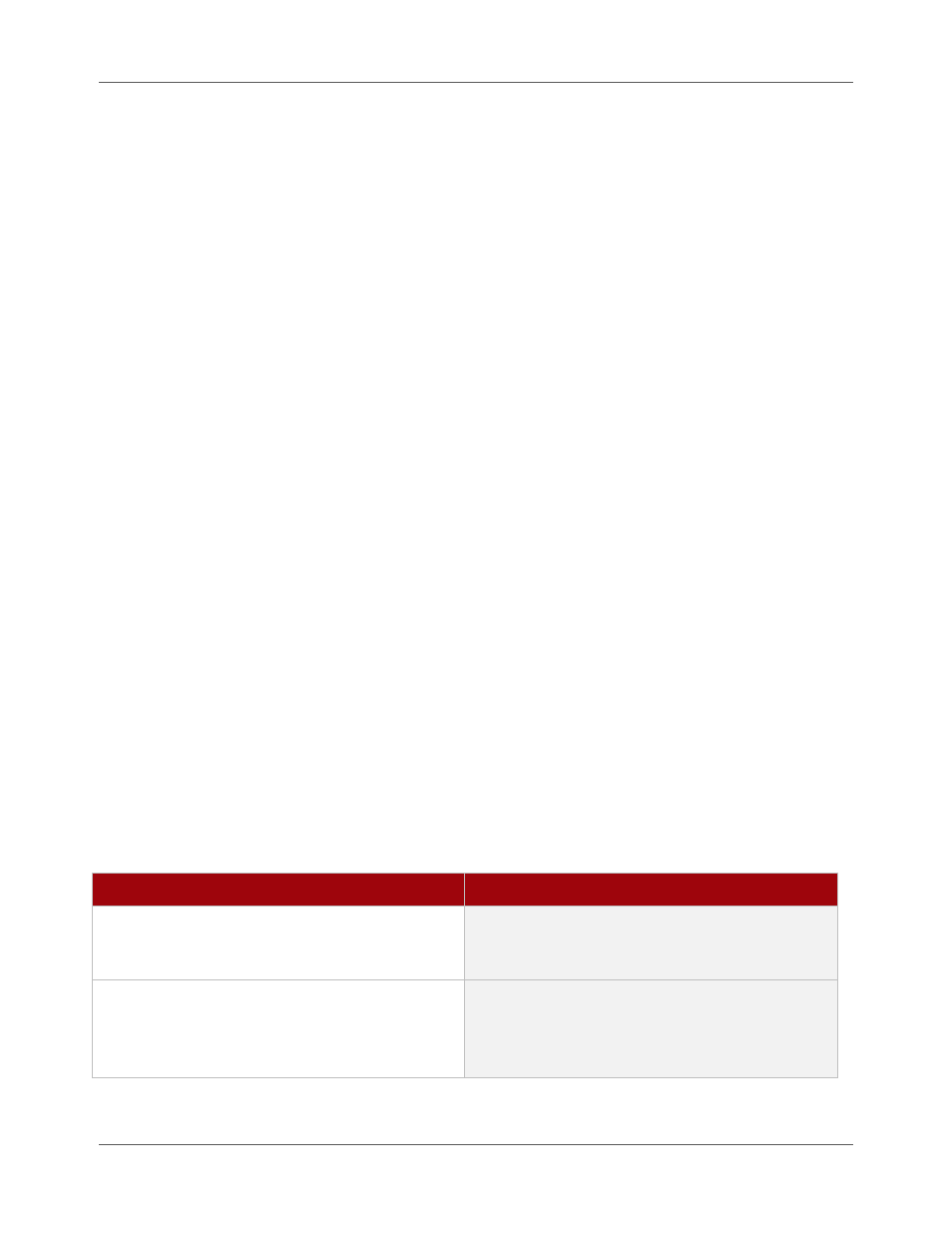

Procedure

Procedure

Details

1.

Go to the System Variables menu by pressing:

MENU > 0 (Next) > 6 (System) > F1 (Type) >

Variables

2.

Move the cursor to $AWELEPM and

press ENTER.

If you have more than one weld equipment in your

system, there will be an index for each equipment,

so the first equipment will appear as

$AWELEPM[1].