4 auto tuning, Auto tuning -3, 4 auto tuning caution – Yokogawa YVP110 User Manual

Page 72: Important

<12. Transducer Block>

12-3

IM 21B04C01-01E

12.4 Auto Tuning

CAUTION

This function strokes the valve over its full range.

Do not execute while valve is controlling the

process. Keep away from the movable parts to

avoid injury.

Auto tuning checks the valve responses and

automatically tunes control parameter settings. The

actions to be performed can be chosen as shown

in the table below (for how to carry out auto tuning,

see Chapter 5, “Setup”). Before carrying out auto

tuning, change the modes of the AO function block

and transducer block to O/S.

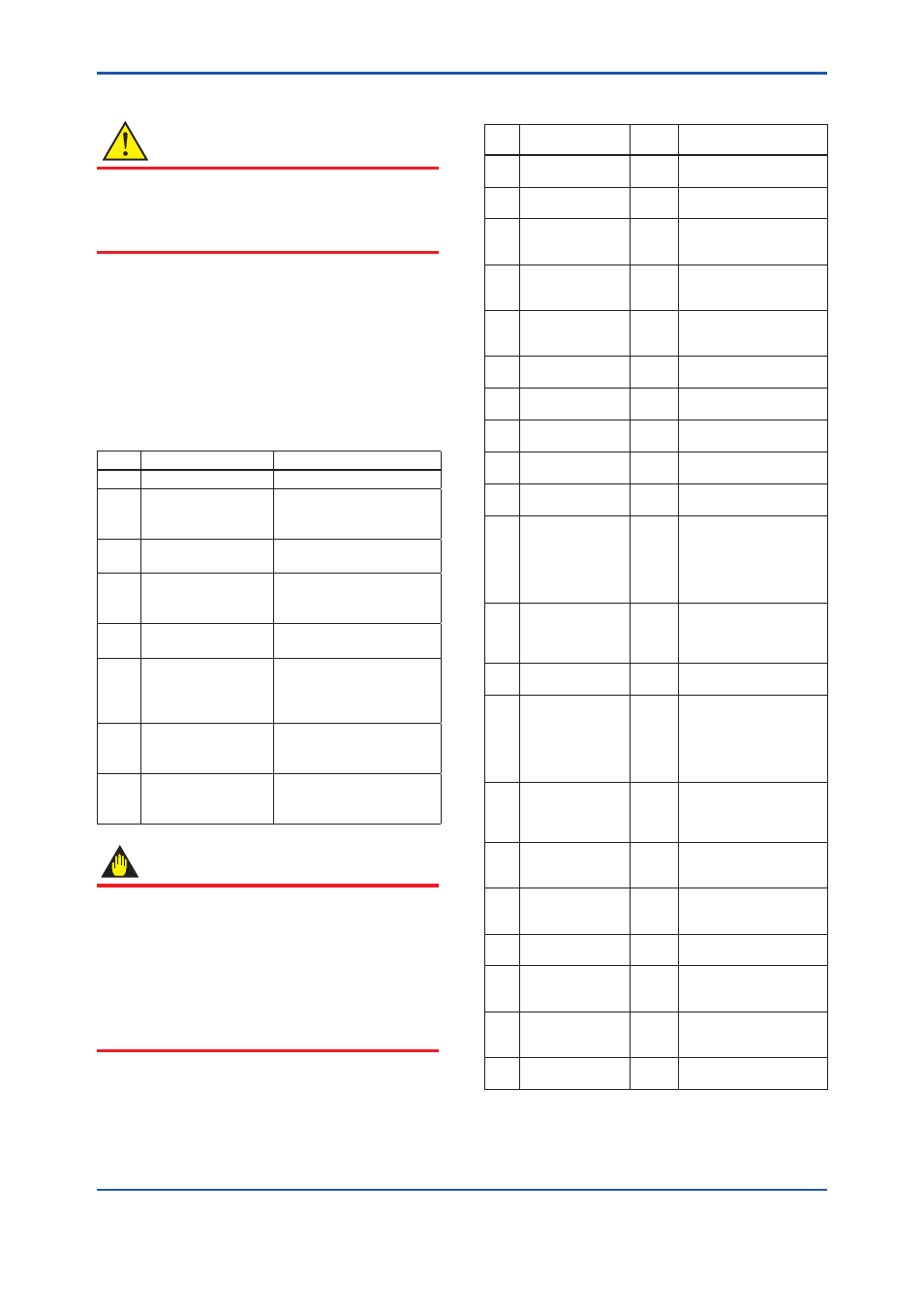

Table 12.2

Types of Auto Tuning

value

Comment

Description

1

Off

—

2

Travel calibration

tuning at stop point

Travel calibration at the

tight-shut and full-open

positions

3

Control parameter

tuning

Tuning of control

parameters

4

Travel calibration at

stop point & Control

parameter tuning

Sequential execution

of travel calibration and

control parameter tuning

5

Cancel execution

Cancellation of auto

tuning execution

6

Travel calibration at

stop point without

time out (for very

large valve)

Zero-point and span

calibration at the tight-shut

and full-open positions

without time out

7

Travel calibration

with step by step (for

very large valve)

Step-by-step travel

calibration at the tight-shut

and full-open positions

255 Self-check only

Execution of self-

diagnostics only (without

parameter tuning)

IMPORTANT

Auto Tuning in YVP110 sets the 0 % point at the

position where the valve is fully closed and 100%

point at the position where the valve stem stops

against the mechanical stopper(fully open). If it

is necessary to adjust the zero point and span

precisely to the rated stroke of the valve, carry

out travel calibration which is described later in

this chapter after the Auto Tuning.

The result of auto tuning, which is written to AUTO_

TUNE_RESULT, may be an error or warning. An

error invalidates the tuning and does not update the

parameter settings.

Table 12.3

AUTO_TUNE_RESULT & TRAVEL_

CALIB_RESULT

Value

*

1

Comment

Error

*

2

/Warning

Description

1 Succeeded

—

Auto tuning/Travel

calibration has succeeded.

2 Canceld

—

Auto tuning has been

canceled.

21 Exhaust air

pressure warning

W

The measured exhaust

pressure exceeds ±60

Kpa.

22 Small supply air

pressure warning

W

The measured supply air

pressure is less than 100

kPa.

23 Large supply air

pressure warning

W

The measured supply air

pressure is greater than

800 kPa.

40 Offset drift warning

W

The offset falls outside the

normal operation range.

42 Large Response

speed warning

W

Waiting time for measuring

time > 40 seconds

43 Large hysteresis

warning

W

Hysteresis > 30%

44 Large slip width

warning

W

Slip width > 5%

60 Small angle span

warning

W

Rotation-angle span < 15

degrees

61 Large angle span

warning

W

VALVE_TYPE is linear and

the rotation-angle span

exceeds 55 degrees; or

VALVE_TYPE is rotary and

the rotation-angle span

exceeds 95 degrees.

62 50% angle warning

W

VALVE_TYPE is linear and

the rotation angle at the

50% position exceeds ±20

degrees.

100 Small angle span

error

W

Rotation-angle span < 5

degrees

101 Large angle span

error

E

VALVE_TYPE is linear and

the rotation-angle span

exceeds 60 degrees; or

VALVE_TYPE is rotary and

the rotation-angle span

exceeds 100 degrees.

102 50% angle error

E

VALVE_TYPE is linear and

the rotation angle at the

50% position exceeds ±25

degrees.

103 Linear adjust error

E

FINAL_VALUE.value falls

outside 50 ±10% at 50%

position.

120 Offset

measurement failed

error

E

Offset measurement has

failed.

121 Gain measurement

failed error

E

Gain measurement has

failed.

122 Response speed

measurement failed

error

E

Response speed

measurement has failed.

123 Hysteresis

measurement failed

error

E

Hysteresis measurement

has failed.

255 In operation

—

Auto tuning is being

executed.

*1:

Number 103 is not shown for AUTO_TUNE_RESULT.

Number 1 through 44 and 120 through 123 are not shown

for TRAVEL_CALIB_RESULT.

*2:

E stands for ‘Error’, and W stands for ‘Warning’.