Appendix 6. manual tuning guideline, A6.1 general, A6.2 control parameter tuning procedure – Yokogawa YVP110 User Manual

Page 149: A6.1, A6.2, A-38

A-38

IM 21B04C01-01E

Appendix 6. Manual Tuning Guideline

A6.1 General

The YVP110 can improve controllability by properly

performing the manual tuning of control parameters

for each valve and actuator.

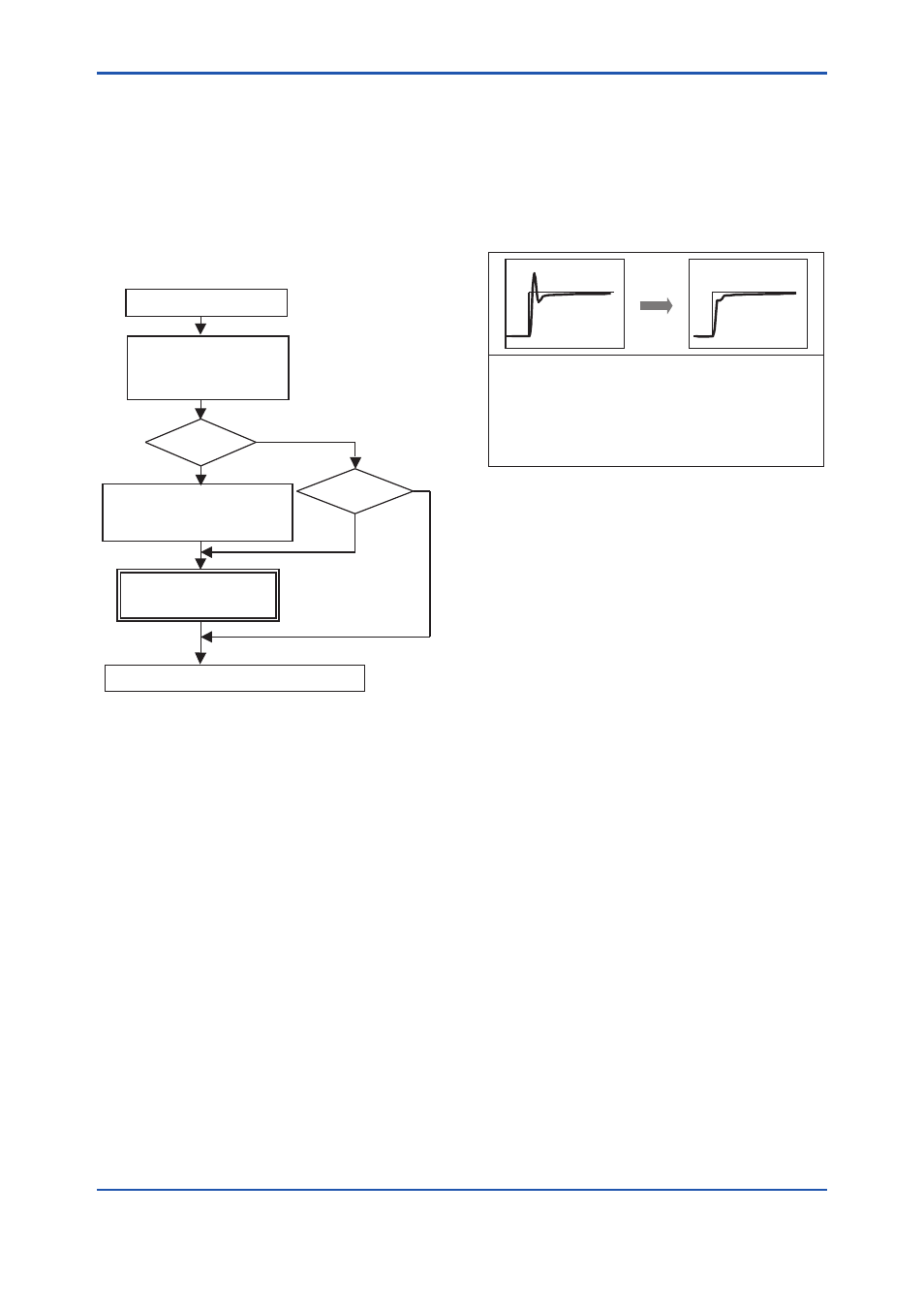

The following shows the whole tuning procedure.

Manual Tuning

(Manually adjust control parameters)

Check value

actions (5.4)

Carry out Auto Tuning (5.3)

(Adjust zero-point and span,

and set control parameters)

Successful?

Yes

No

NG

Adjust zero-point and span at fully

closed/opened positions (5.3, 12.4)

and travel calibration (5.3, 12.5)

Set basic parameters (5.2)

Set transducer block’s parameters (5.5)

Good

FA0601.ai

If you cannot obtain expected response

characteristics by Auto Tuning, verify the 10% step

response and compare your response waveform

with three types of response waveforms shown

in A6.2. Adjust parameters by referring to the

procedure of a waveform that has characteristics

similar to those of your waveform.

If Auto Tuning fails, adjust the zero-point and

the span, then set the parameters by referring

to the default settings (factory settings) or tuning

examples in A6.3. Then verify the 10% step

response and adjust the parameters according to

the procedure described in A6.2.

(For detail about the control parameters, see

section A6.4.)

Before carrying out parameter tuning, change the

modes of the AO function block and transducer

block to O/S.

A6.2 Control Parameter Tuning

Procedure

[1] Fast response

[Characteristics]

Since both the rise and tracking of the target value are fast,

a V-shaped overshoot occurs. You can obtain a better

response by maintaining the response speed and reducing

overshoot.

This waveform is typically observed in small capacity

actuators.

FA0602.ai

(1) Modifying overshoot

• Increase the value for SERVO_RATE to reduce

an excessively rapid response. Verify the 10%

step response and increment the value by 0.2.

• If a significant improvement effect cannot be

obtained by only incrementing the value for

SERVO_RATE in small steps of approximately

5% or less, input the value in small steps in

BOOST_ON_THRESHOLD [2] and decrement

the value for BOOST_VALUE [1] by 2 to

decrease the boost.

• The same boost value is set on both the air

delivery and exhaust sides using Auto Tuning. If

the overshoot on the exhaust side is larger than

that on the air delivery side for a double-acting

model, input a negative value in

X_BOOST_VALUE[1][2], without changing the

value of 0 in

X_BST_ON_THRESHOLD[1][2] and

X_BST_OFF_THRESHOLD[1][2]. First, try to

input a negative value of half that of BOOST_

VALUE [1] [2], and if necessary, increment or

decrement the value by 1.

• If necessary, increment or decrement the value

for SERVO_GAIN by 30.

(2) Improving the stabilization time

Decrease the value for SERVO_RESET to improve

the capability of tracking the target value. Verify the

10% step response and decrement the value by 3.