Maintenance, 1 general, 2 periodic inspections – Yokogawa YVP110 User Manual

Page 39: 1 cleaning the fixed nozzle, Maintenance -1, General -1, Periodic inspections -1 6.2.1, Cleaning the fixed nozzle -1, Caution

<6. Maintenance>

6-1

IM 21B04C01-01E

6. Maintenance

6.1 General

The modular structure of the YVP110 increases the

ease of maintenance work. This chapter describes

cleaning and part replacement procedures that

should be done for maintenance of the YVP110.

The YVP110 is a precision instrument; read the

following carefully when carrying out maintenance.

For calibrations, see Chapter 5.

CAUTION

Precautions for ATEX flameproof type and

type nA instruments

• Flameproof type and type nA instrumets

must be, as a rule, removed to a non-

hazardous area for maintenance and be

disassembled and reassembled to the

original state.

• On the flameproof type and type nA

instruments the terminal cover is locked by

an Allen head bolt (shrouding bolt). When

a shrouding bolt is driven clockwise by an

Allen wrench, it is going in and cover lock is

released, and then the cover can be opened.

When a cover is closed it should be locked

by a shrouding bolt without fail. Tighten the

shrouding bolt to a torque of 0.7 N·m.

Shrouding Bolt

F0601.ai

Figure 6.1

Shrouding Bolts

6.2 Periodic Inspections

To maintain problem-free plant operation, periodic

inspections are essential. At each periodic

inspection, be especially careful when ensuring

that:

• No external damage can be seen.

• No leakage from the YVP110 or the piping

around it can be detected.

• No build up in the drain, or dust or oil adhering

to the air supply line has occurred.

6.2.1 Cleaning the Fixed Nozzle

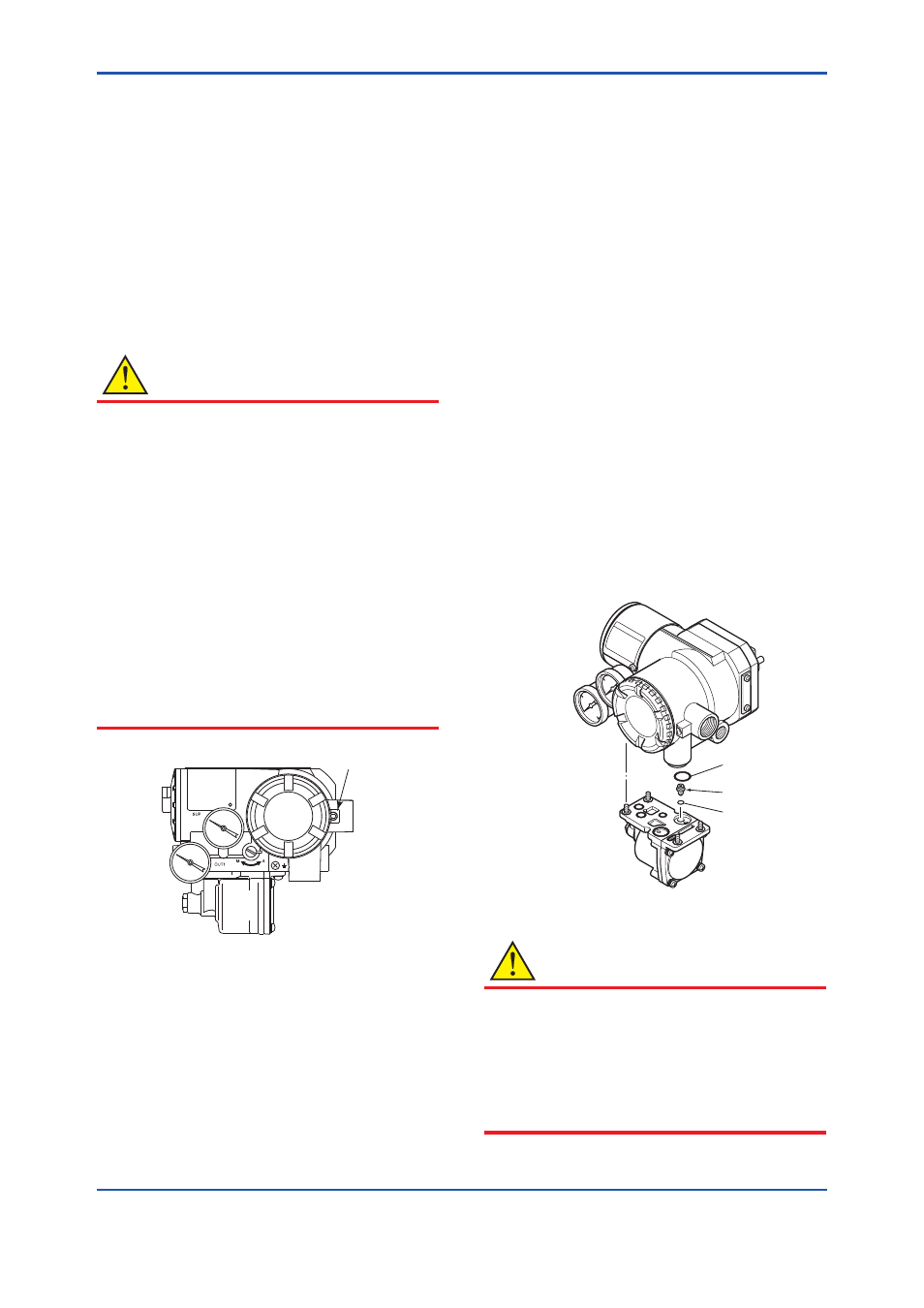

The fixed nozzle of the YVP110 is attached to the

control relay’s surface that engages the YVP110’s

main structure (see Figure 6.2). Detach the

control relay from the main structure of YVP110 by

following the instruction shown in 6.3.1. Thread a

wire with a 0.25-mm diameter through the nozzle to

clean it. After cleaning the nozzle, place the nozzle

and O-ring at the original position and attach the

control relay again.

F0602.ai

Nozzle

O-ring

O-ring

Figure 6.2 Cleaning the Nozzle

CAUTION

All the O-rings used for the sealing of pneumatic

signal circuits are made of silicon rubber. The

sealing capability is degraded if general silicon

grease is applied. When applying grease to a

sealing part, use a type of grease compatible

with silicon rubber, such as fluoride grease and

grease for silicon rubber.