5 troubleshooting auto tuning, Troubleshooting auto tuning -3 – Yokogawa YVP110 User Manual

Page 111

<20. Troubleshooting>

20-3

IM 21B04C01-01E

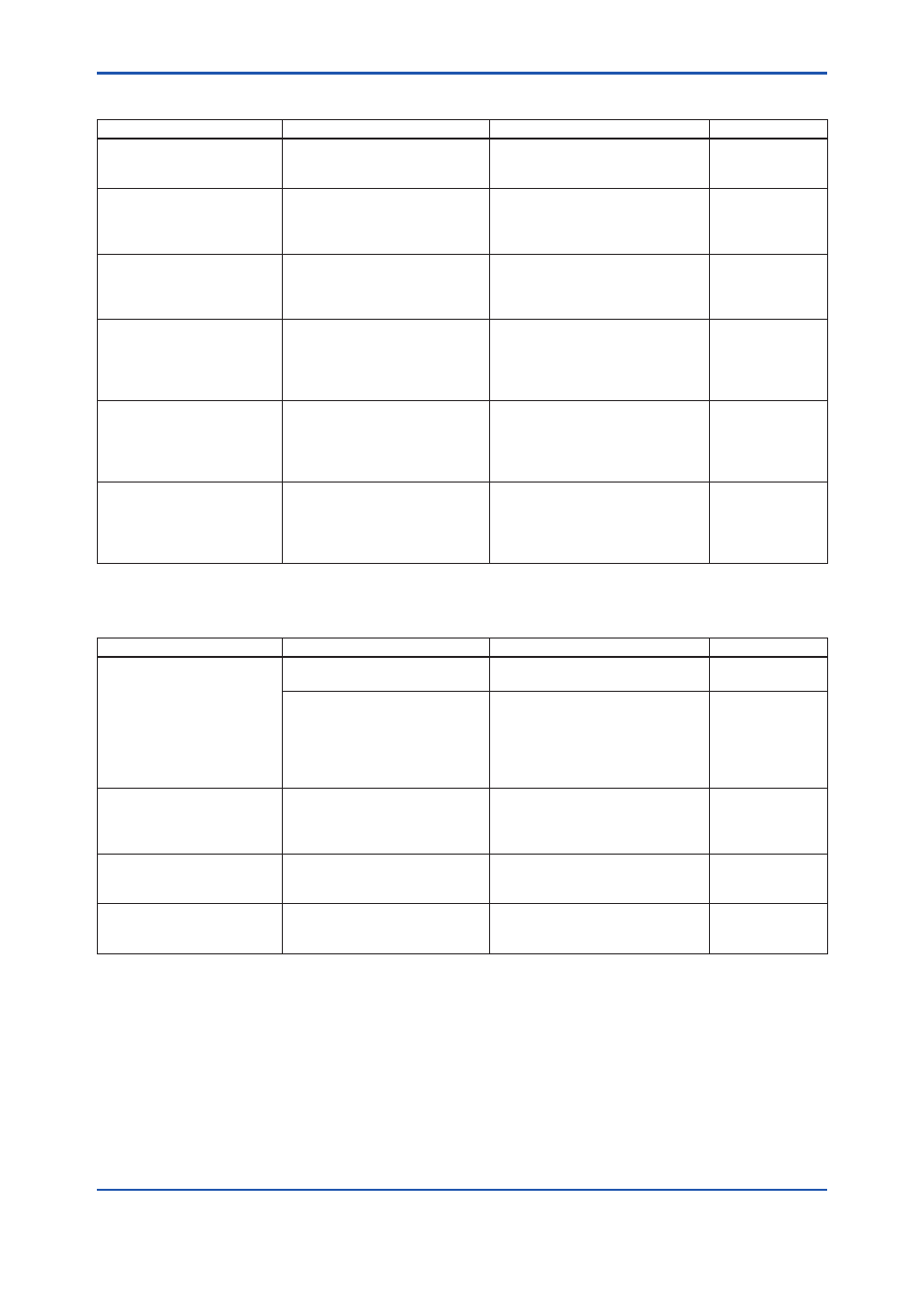

20.5 Troubleshooting Auto Tuning

Problem

Presumed Cause

Remedy

Ref. Section

Auto tuning requests are

rejected.

Either or both of the A/O block

and transducer block are not in

O/S mode.

Change the target modes of the AO

and transducer block to O/S.

Appendix 1

When auto tuning has

finished, AUTO_TUNE_

RESULT changes value to

an index from 21 to 23.

There is something wrong with

the air supply pressure or spring

range.

Check whether the measured

pressure reading nearly equals

the actual pressure. See the

descriptions for auto tuning.

5.3,

12.4

When auto tuning has

finished, AUTO_TUNE_

RESULT changes value to

index 40 or 120.

There is something wrong with

the operation point of the I/P

module. SERVO_OFFSET could

not be measured.

If there is nothing wrong with the

air supply pressure and piping,

contact the nearest service station

or representative office.

—

When auto tuning has

finished, AUTO_TUNE_

RESULT changes value to

an index from 42 to 44, or

from 120 to 123.

The measured time delay

constant, hysteresis, and/or slip

width of the valve is excessively

large.

Check whether they meet the

characteristics specified for the

valve. See the descriptions for auto

tuning.

5.3,

12.4

When auto tuning has

finished, AUTO_TUNE_

RESULT changes value to

an index from 60 to 62, or

from 100 to 103.

The span of rotation angle is

incorrect or the 50% position

deviation from the horizontal

level is too large.

Correct the installation and try auto

tuning again.

Chapter 3,

5.3

When auto tuning has

finished, AUTO_TUNE_

RESULT changes value to

an index from 60 to 62, or

from 120 to 123.

The valve hysteresis is large.

Carry out manual tuning.

Appendix 6

20.6 Troubleshooting Position, Pressure, and Temperature Sensors

Problem

Presumed Cause

Remedy

Ref. Section

The position sensor signal

remains unchanged.

The feedback lever is not

properly attached.

See the descriptions for positioner

installation.

Chapter 3

The position sensor has failed

or there is breakage in the

cable between the sensor and

amplifier.

If ADVAL_BW does not change

value when the shaft rotates, it

may be necessary to replace

the position sensor. Contact our

nearest representative or service

station.

—

The positon sensor signal

is unstable, or XD_ERROR

indicates error 124.

The position sensor has failed

or there is breakage in the

cable between the sensor and

amplifier.

It may be necessary to replace

the position sensor. Contact the

nearest representative or service

station.

—

The pressure sensor signal

is unstable, or XD_ERROR

indicates error 121.

The pressure sensor has failed. It may be necessary to replace

the amplifier. Contact the nearest

representative or service station.

—

The temperature sensor

signal is unstable, or XD_

ERROR indicates error 120.

The temperature sensor has

failed.

It may be necessary to replace

the amplifier. Contact the nearest

representative or service station.

—