Yokogawa YVP110 User Manual

Page 26

<3. Installing YVP110 on Actuator>

3-2

IM 21B04C01-01E

(2) Fixing the YVP110 to Actuator with Bracket

After fixing the bracket to the YVP110, attach it

to the actuator with the specified bolts.

Depending on the shapes of the bracket and

actuator, the working space at the rear of the

YVP110 where the feedback shaft is positioned

may be quite narrow, making installation work

tricky. In such a case, the entire procedure

may be made much easier by attaching

the feedback lever to the feedback shaft as

described in step (3), prior to carrying out step

(2). Check the space behind the YVP110

beforehand.

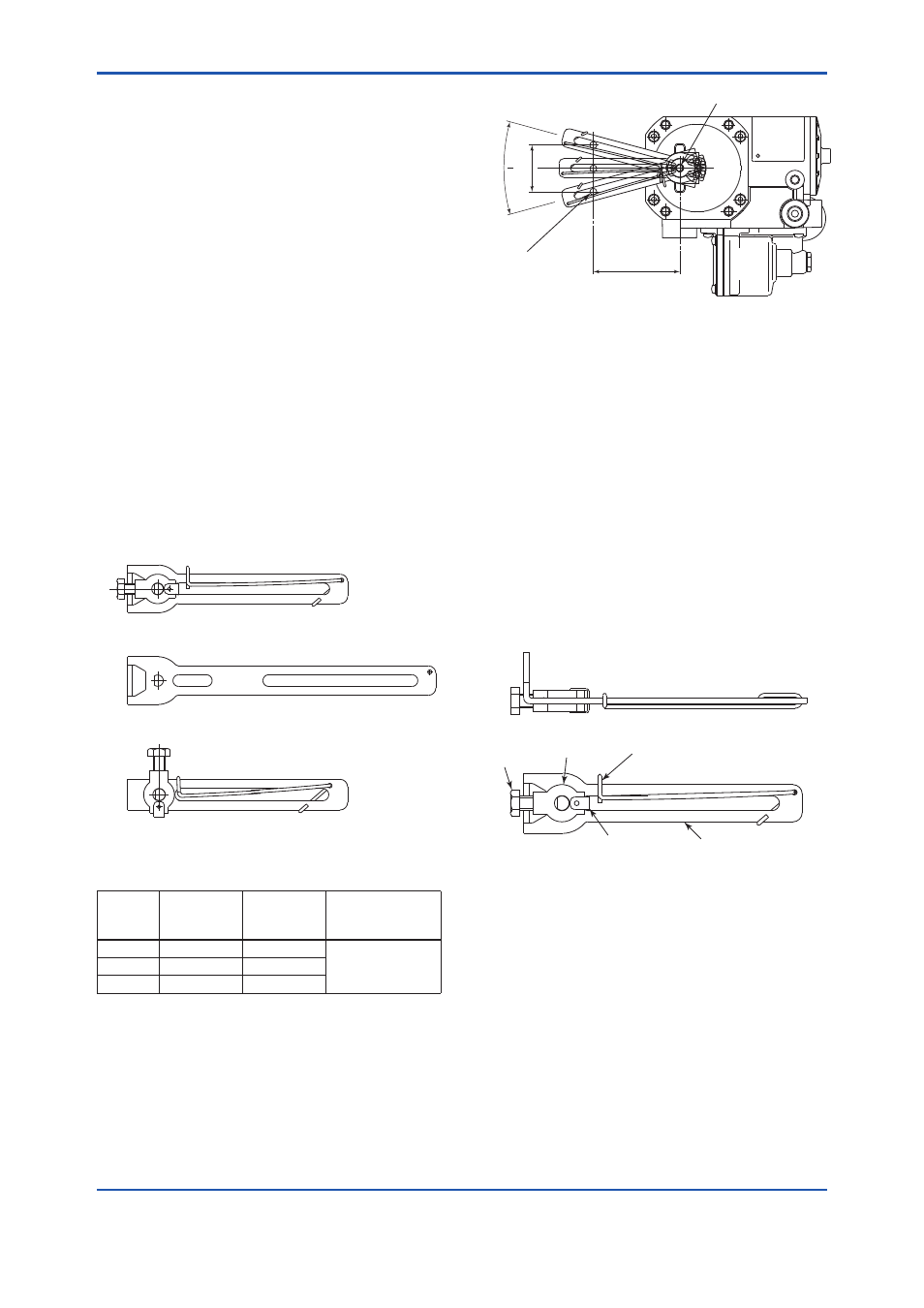

(3) Attaching Feedback Lever

The YVP110 with option code /LV1 comes with

two different feedback levers, (1) and (2) shown

below, and the one with option code /LV2

comes with lever (3). Check the specifications

of the levers shown in Table 3.1 and Figure

3.2 and choose the lever most suitable for the

control valve used.

F0302.ai

(1) F9176HA

(2) F9176HC

(3) F9176HD

Figure 3.2

Feedback Levers

Table 3.1

Specifications of Levers

Lever

Model

Stroke (X)

Pin-to-shaft

Distance (L)

Allowable Range of

Rotation Angle of

Feedback Shaft(θ)

F9176HA 10 to 60 mm

25 to 75 mm

±10 to 25 degrees

F9176HC 30 to 100 mm 75 to 115 mm

F9176HD 5 to 20 mm

14 to 20 mm

Note: When assembling a YVP110 with a linear-motion actuator,

ensure that the rotation angle of the YVP110’s feedback

shaft does not exceed the allowable range (10 to 25

degrees shown above.

Only if the range of the rotation angle is within this

specification, it is guaranteed that the specified accuracy

can be obtained by linearity correction (see the description

for travel calibration in Section 5.3, “Carrying out Auto

Tuning”).

F0303.ai

L

X

θ

Feedback shaft

Clamp pin

on side of valve

SUP

Figure 3.3

Stroke of Lever

When /LV1 is specified, the hardware for attaching

the lever to the feedback shaft and the spring for

fixing the clamp pin are attached to the F9176HA,

the smaller feedback lever for generally used

mid-capacity actuators. Thus, when using the

F9176HC, the feedback lever for high-capacity

actuators, detach and use the hardware and spring

from the F9176HA. See Figure 3.4. To do so, first

detach the spring <4>. Then, detach the clip <1>

and remove the hardware <2> and <3>. Attach <1>

to <4> to the F9176HC feedback lever for high-

capacity actuators in the reverse order.

The hardware and the spring attached to the /LV2

lever is not compatible with those for the /LV1 lever.

F0304.ai

<3>

<2>

<4>

<1>

Lever

Figure 3.4

Disassembling a Lever Assembly

When determining which lever to use, follow the

procedure below to make a linkage between the

YVP110 positioner and control valve’s stem via the

clamp and lever. The adjustment of this linkage is

a decisive factor for determining the characteristics

of the control valve combined with the YVP110

positioner.

(1) Insert the YVP110’s feedback shaft into the

small hole on the stopper side of the lever as

shown in Figure 3.5.