Wiring diagram option identification – Reznor RECC Unit Installation Manual User Manual

Page 73

Form I-MAPSIII&IV, P/N 222917R9, Page 73

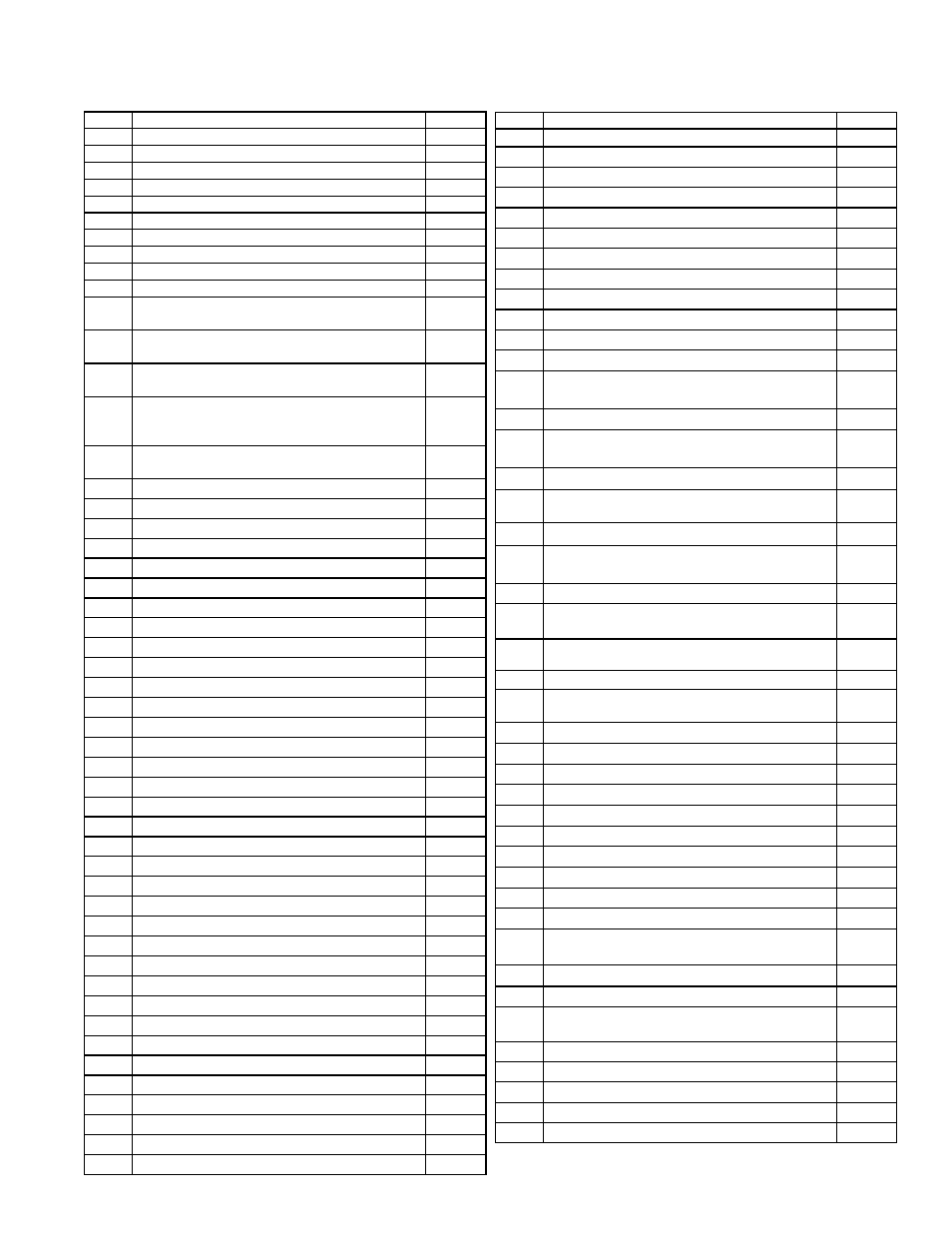

Wiring Diagram Option Identification

The Option Codes for these electrical options are shown on the wiring diagram.

Option Brief Description

Installed

AG70

Modulating Gas Control

Factory

AK5

208/3 Supply Voltage

Factory

AK6

230/3 Supply Voltage

Factory

AK7

460/3 Supply Voltage

Factory

AK8

575/3 Supply Voltage

Factory

AN2

Contactor

Factory

AN10

Motor Starter

Factory

ARD3

Motorized Intake Damper (for Option ER)

Factory

AR8

Two-Position (open/closed) O/A Damper

Factory

AR25

Modulating OA/RA Dampers requires Option GF control

Factory

AR2D

Motorized Outside Air Damper and cabinet opening for

power exhaust (Option PE)

Factory

AR2G

Modulating OA/RA Dampers (requires Option GF control)

w/gravity exhaust hood & damper

Factory

AR2H

Modulating OA/RA Dampers (requires Option GF control)

w/exhaust opening in cabinet

Factory

AR2K

Outside Air w/3-position damper, Return/Exhaust Air

w/3-position damper (MAPS

®

unit), gravity damper on

exhaust outlet

Factory

AR2L

100% Outside Air - on/off inlet damper; gravity damper

on exhaust outlet

Factory

AUC9

Hot Gas Bypass

Factory

AUR1

Modulating Reheat

Factory

BA6

Unit flush mounted disconnect on/off switch

Factory

BA7

Dual Disconnects for Emergency - Cab C

Factory

BC2

Convenience Outlet (requires separate power supply)

Fld&Fctry

BD5

Firestat, 200°F (field installed)

Field

BE6

Return Air Temperature & Humidity Sensors

(Opt ER1_) Factory

BE9

Monitors Temperature from Evaporator Coil

Factory

BE10

Monitors Mixed Air Temperature

Factory

BE11

Monitors Duct Static Pressure

Fld&Fctry

BE12

Monitors Building Static Pressure

Fld&Fctry

BE13

Return Air Temperature Sensor

Field

BE14

Return Air Humidity Sensor

Field

BE15

Space CO2 Sensor

Fld&Fctry

BE16

DDC Monitoring Dirty Filter Switch

Factory

BE17

Photoelectric Smoke Detector

Field

BE18

Dirty Filter Pressure Switch

Factory

BE19

OA/RA Override (requires BHB6)

Fld&Fctry

BE20

Manual Schedule Override

Factory

BE21

Contacts only for Occupied/Unoccupied Switch

Factory

BE28

Dirty Filter Switch (for Option ER1)

Factory

BG9

Exhaust Fan Relay

Fld&Fctry

BHB5

Lon Communication Plugin Module

Factory

BHB6

Add'l Inputs & Outputs for Main Controller

Fld&Fctry

BHC5

LON card for Option ER1

Factory

BP4

High and Low Gas Pressure Switches

Factory

BW5D

DDC Monitored Dirty Filter Sensor

Fld&Fctry

CL77

Space Temperature Sensor/Override

Field

CP__

Disconnect Switch

Field

D15

Neutral Air/Discharge Air Temperature Control

Fld&Fctry

D16

Space Temperature Control w/Discharge Air Reset

Fld&Fctry

D17

RECC - Neutral Air/Discharge Air Temperature Control

Fld&Fctry

D18

RECC - Space Temperature Cntrl w/Discharge Air Reset

Fld&Fctry

DT7

Space Relative Humidity Sensor/Control

Field

EFA_

Exhaust Fan Motor HP (for Opt ER1_)

Factory

Option Brief Description

Installed

EFC4

Building Pressure Control for EFD1 (for Opt ER1_)

Fld & Fctry

EFC7

Proportional to MAPS

®

Control for EFD1 (for Opt ER1_)

Factory

EFC9

Adjustable Constant Volume Control for EFD1 (ER1_)

Factory

EFD1

Exhaust Fan Motor Variable Frequency Drive (ER1_)

Factory

EFD2

Variable Frequency Drive (for PE Options)

Field

EG1

Single stage control - RECB, REDB

Factory

EG3

Multi stage control - RECB, REDB

Factory

EL_

Exhaust Fan Motor Type (for Option ER1_)

Factory

EM_

Exhaust Fan Drive (for Option ER1_)

Factory

EN2

Contactor (for Option PE or ER1_)

Factory

EN10

Starter (for Option or ER1_)

Factory

ER1_

Energy Recovery Module

Field

GF1

DDC Damper Control with Remote Manual Potentiometer

(0-5V input signal)

Fld&Fctry

GF2

DDC Two-Position Damper Control

Fld&Fctry

GF4

DDC Four-Position Damper Control based on two input

switches

Fld&Fctry

GF5

DDC Damper Control with Building Pressure Monitor

Fld&Fctry

GF6

DDC Damper Control with Mixed CO2 Control (0-2000

ppm)

Fld&Fctry

GF7

DDC Damper Control with 2-Position Enthalpy Control

Fld&Fctry

GF8

DDC Damper Control with Dual Reference Enthalpy Control Fld&Fctry

GF9

DDC Damper Control with Dry Bulb Mixed Air Economizer Fld&Fctry

JHT1

Additional electrical components required for curb furnace

JH25 (applies to RDCB/RDDB 500MBH)

Factory

JHT2

Additional electrical components required for curb furnace

JH30 (applies to RDCB/RDDB Cabinet C 1000 MBH)

Factory

PE_

Power Exhaust

Fld&Fctry

PL4

Redundant phase loss/reversal protection & high/low

voltage

Factory

RB3

Remote Module with Display, Controls, and Alarm Light

Field

RB4

Hand held control access with 12-ft cable and alarm light

Field

SA1

Duct Photoelectric Smoke Detector

Fld&Fctry

SFA_

Supply Fan Motor HP (for Option ER1_)

Factory

SFC3

Neutral Pressure Control for SFD1 (for Option ER1_)

Factory

SFC9

Adjustable Constant Volume Control for SFD1 (ER1_)

Factory

SFD1

Supply Fan Motor Variable Frequency Drive (ER1_)

Factory

SL_

Supply Fan Motor Type (for Option ER1_)

Factory

SN2

Supply Fan Contactor (for Option ER1_)

Factory

SN10

Supply Fan Starter (for Option ER1_)

Factory

VFC2

Variable Frequency Drive DDC External Control 0-5V Input

(requires BHB6)

Fld&Fctry

VFC3

VFD Duct Static Pressure Control (0 to 2.5" w.c.)

Fld&Fctry

VFC4

VFD Building Static Pressure Control (-0.5 to 0.5)

Fld&Fctry

VFC5

Variable Frequency Drive Space CO2 Control (0-2000 ppm) Fld&Fctry

VFC7

Variable Frequency Drive 3-Speed Wall-Mounted Control

Fld&Fctry

VFC8

Variable Frequency Drive 4-Speed Wall-Mounted Control

Fld&Fctry

VFC9

Adjustable Constant Volume Control

Fld&Fctry

VFD2

Variable Frequency Drive

Field

VFD3

Variable Frequency Drive field provided

Factory

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual