0 mounting (cont'd), 4 mounting on a roof curb (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 12

Form I-MAPSIII&IV, Page 12

Installation Instructions

for Down Discharge

Roof Curb, Option

CJ31, for MAPS

®

Cabinet Sizes A, B, and

C

NOTE: For A, B, or C with

energy recovery Option

ER1, see page 14.

CAUTION: Before installation, recheck to be sure that the correct curb

has been ordered. Be sure that the curb selected matches the unit

ordered. Verify the dimensions of the curb received with the appropriate

dimension table.

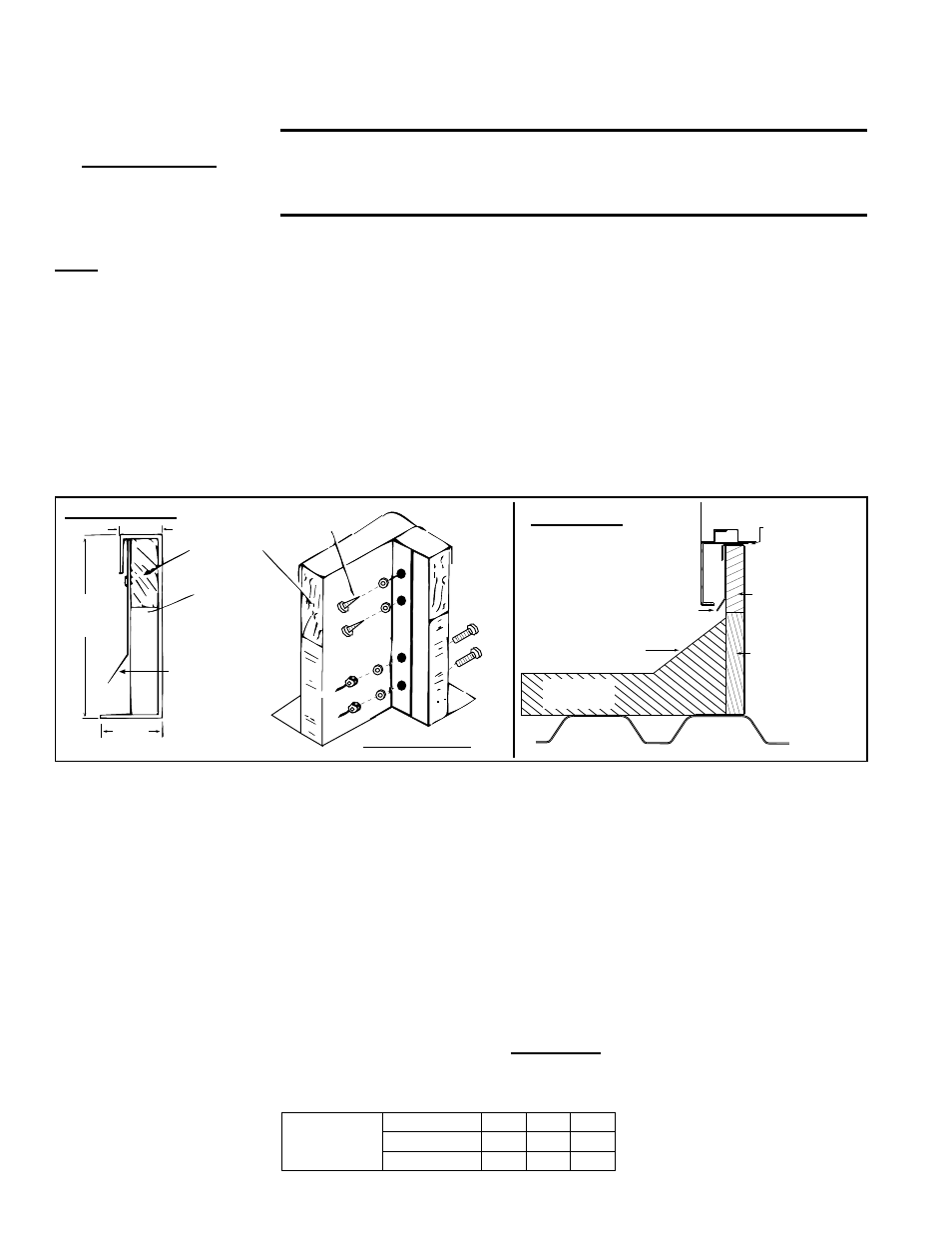

1. Position the roof curb ends (Code A) and sides (Code B) as shown in the drawing

in

FIGURE 7A. Fasten with bolts and lag screws as illustrated in the corner detail

(

FIGURE 7B).

2. Install bottom opening ductwork. Use the sheetmetal screws to attach the dividers

(

Codes C1, C2, D1, D2, E, & F in FIGURE 7A). Attach the return air duct angles

(

Codes G & H) to the attached end and side and to the roof curb. NOTE: If the

system does not have a return air opening, Codes F, G, & H may be installed in

the curb but are not required.

3. Check the roof curb for squareness. The curb must be adjusted so that the

diagonal measurements are equal within a tolerance of ±1/8” (±3mm).

4. Level the roof curb. To ensure a good weatherproof seal between the unit curb cap

and the roof curb, the roof curb must be leveled in both directions with no twist end

to end. Shim as required and secure curb to the roof deck before installing flashing

(See Curb Detail in

FIGURE 7B).

FIGURE 7B - Option

CJ31 Downflow Roof

Curb Cross Section and

Corner Detail

MUST be sealed

between curb cap

and top of curb

Cabinet

2x4 Wood Nailer

Counter Flashing

(by installer)

Cant Strip

(by installer)

Weld, bolt, or lag screw curb to deck structure.

Roofing Felts

(by others)

Insulation

14

(356mm)

1-7/8(48mm)

4

(102mm)

2 x 4 Wood

Nailer

1-1/2 x 3 lb

Fiberglass

Flashed by the

installer (flashing

must be under lip

of curb)

Lag Screw

Cap

Screws

Curb Detail

Corner Detail

Curb Section

5. Install field-supplied flashing.

6. Be

fore placing the MAPS

®

unit or optional duct furnace (Option JH25 or JH30) on the curb:

□

If ductwork is being installed from the top, slide the ductwork down into the

discharge and return air openings. Ductwork should be sized slightly smaller with

a minimum 3/4" duct flange that will rest on and be attached to all sides of the duct

connection. See duct connection requirements in Paragraph 6.4.

□

Apply 1/4" x 1-1/4" foam sealant tape to both the top surface of the curb rails

and the top surface of the perimeter of the integral dividers, being sure to make

good butt joints at all corners. The sealant tape must be applied to prevent water

leakage into the curb area due to blown rain and capillary action.

□

If installing an optional duct furnace curb section (Option JH), place it on the roof

curb before the unit. See Paragraph 5.4.3.

□

When it is time to lift the MAPS

®

unit or optional duct furnace onto the prepared

curb (See Rigging and Lifting in Paragraph 5.5.), be sure that all of the above

preparations have been made.

IMPORTANT: Verify that the unit will be placed in

the correct airflow orientation to mate properly with the discharge and return air

openings.

5.4 Mounting on a Roof Curb (cont'd)

5.0 Mounting

(cont'd)

5.4.1 Downflow Roof Curbs for MAPS

®

Cabinets A, B, C (cont'd)

5.4.1.1 Curb for Vertical (Down) Airflow (Option CJ31) (cont'd)

Weights by Cabinet

Size* - Downflow Roof

Curb Option CJ31

* See chart on pages 71-72 for cross-

reference by Model Size or Model

and Heat Size to Cabinet Size.

Option CJ31

Roof Curb

Weight

Cabinet Size *

A

B

C

lbs

93

105

235

kg

42

48

107

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual