3 wiring diagram, unit wiring requirements, And optional convenience outlet, 4 control wiring – Reznor RECC Unit Installation Manual User Manual

Page 43: 5 blower motor

Form I-MAPSIII&IV, P/N 222917R9, Page 43

Before initial startup, connect refrigerant pressure gauges to the compressor suc-

tion and discharge lines. At startup, observe the gauges.

If the suction pressure

rises and discharge pressure drops, the compressor is operating in reverse and

should be shut down. (After several minutes of operation in reverse, the compres-

sor’s internal protector will trip. If compressors are repeatedly allowed to restart and

run in reverse, the compressors will be permanently damaged.)

Turn off the power. At

the incoming power connection, switch the 3-phase line voltage wiring connec-

tions before restarting the unit. Recheck the pressure gauges.

CAUTION: Connect pressure gauges to the suction and discharge

lines before startup so that compressor rotation can be checked

immediately. Scroll compressors will be destroyed if operated in

the wrong direction.

7.3 Wiring Diagram,

Unit Wiring

Requirements,

and Optional

Convenience

Outlet

Each unit has a custom wiring diagram in the control compartment. All optional elec-

trical components ordered with the unit are shown on the wiring diagram. Codes for

options ordered are listed across the bottom of the diagram. To identify option codes,

see list in

APPENDIX, page 73.

Keep the wiring diagram and all manuals for future reference

CAUTION: If any of the original wire as supplied with the appliance

must be replaced, it must be replaced with wiring material having

a temperature rating of at least 105°C.

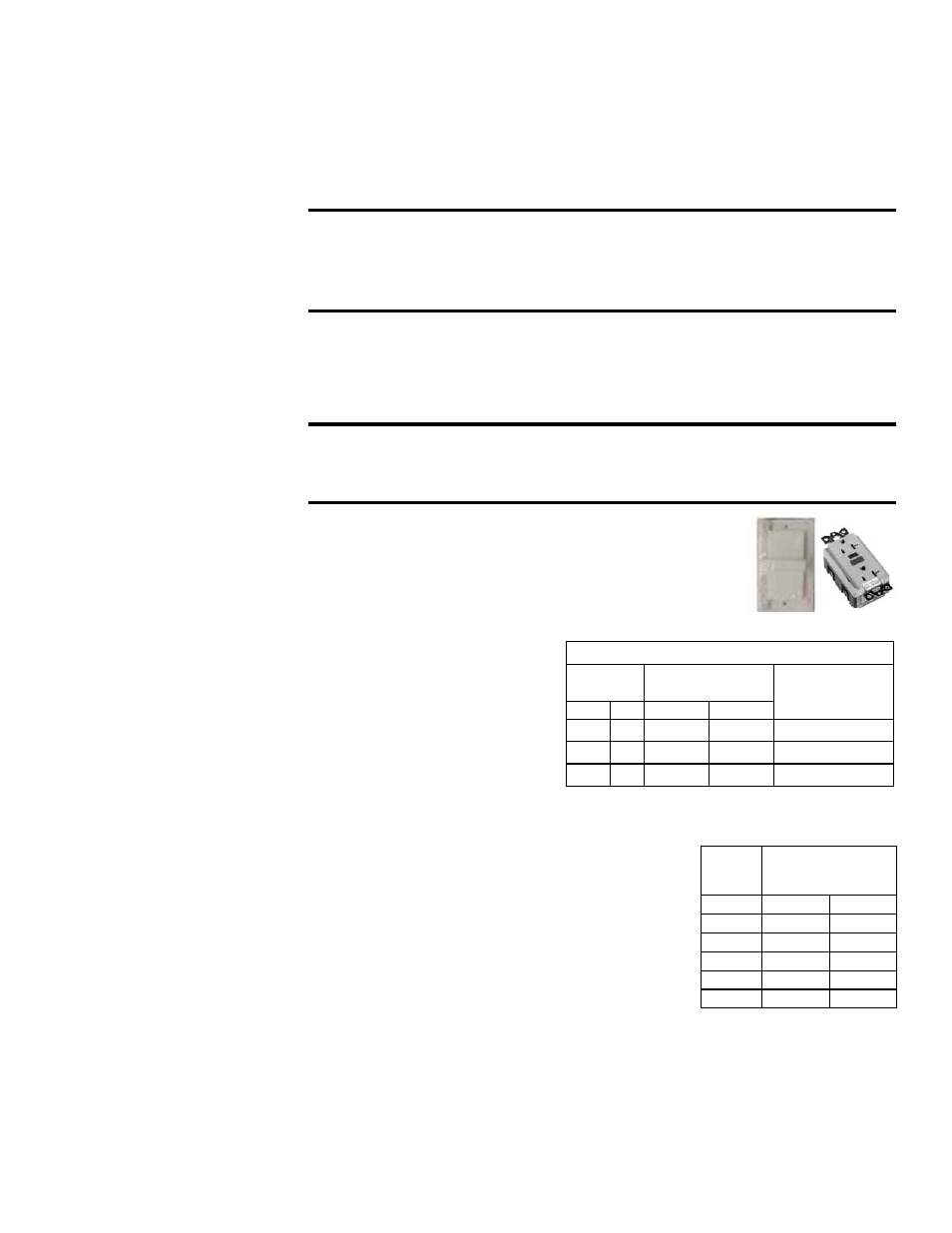

Optional Convenience Outlet, Option BC2

- If the

system was ordered with this option, it will have an external

weatherproof, factory-installed 115V outlet with ground fault

protection. This outlet requires a separate 115 volt power

supply.

7.4 Control Wiring

The unit is equipped with a low

voltage (24V) control circuit. 24V

wires enter the cabinet near the

line voltage entrance and must

be routed over to the low voltage

compartment. Connections are

made at the low voltage terminal

blocks.

Field Control Wiring Length/Gauge

Total Wire

Length

Distance from Unit

to Control

Minimum

Recommended

Wire Gauge

ft

M

ft

M

150

46

75

23

18

250

76

125

38

16

350 107

175

53

14

Refer to the wiring diagram for wiring connections. Refer to the chart for control wire

gauge and length requirements.

Digital Control Wiring

Digital control inputs are low-current, resistance-based

signals. The manufacturer recommends for optimum

temperature control performance that the analog and

digital inputs (zone sensors, discharge air sensors, etc.)

that are connected to the controller be routed in one of

the following manners:

• In separate conduits, isolated from 24VAC controls

and line voltage power to the unit,

OR

Wire

Gauge

Maximum Sensor

Wire Length (Digital

Control)

AWG

Feet

Meters

14

800

244

16

500

152

18

310

94

20

200

61

22

124

38

• If the wires are to be run in the same conduit as the 24 VAC control wiring, the

digital control wiring must use shielded cable and be bundled separately from

24 VAC control wiring. The shield must be drained at the unit and taped on the

opposite end.

Refer to the wiring diagram for making wiring connections.

7.5 Blower Motor

Check the unit rating plate or motor name plate to verify voltage, HP, and type. Use

an amp meter to check motor amps. Amps may be adjusted downward by reducing

blower RPM or increasing duct system static pressure.

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual