2 optional unit monitoring sensors – Reznor RECC Unit Installation Manual User Manual

Page 47

Form I-MAPSIII&IV, P/N 222917R9, Page 47

Maximum Sensor Wire

Length for less than 1°F

Signal Error

Wire

Gauge

Maximum Sensor

Wire Length

AWG

Feet

Meters

16

500

152

18

310

94

20

200

61

22

124

38

Electric Heat

Section

Hot

Air

Cool

Air

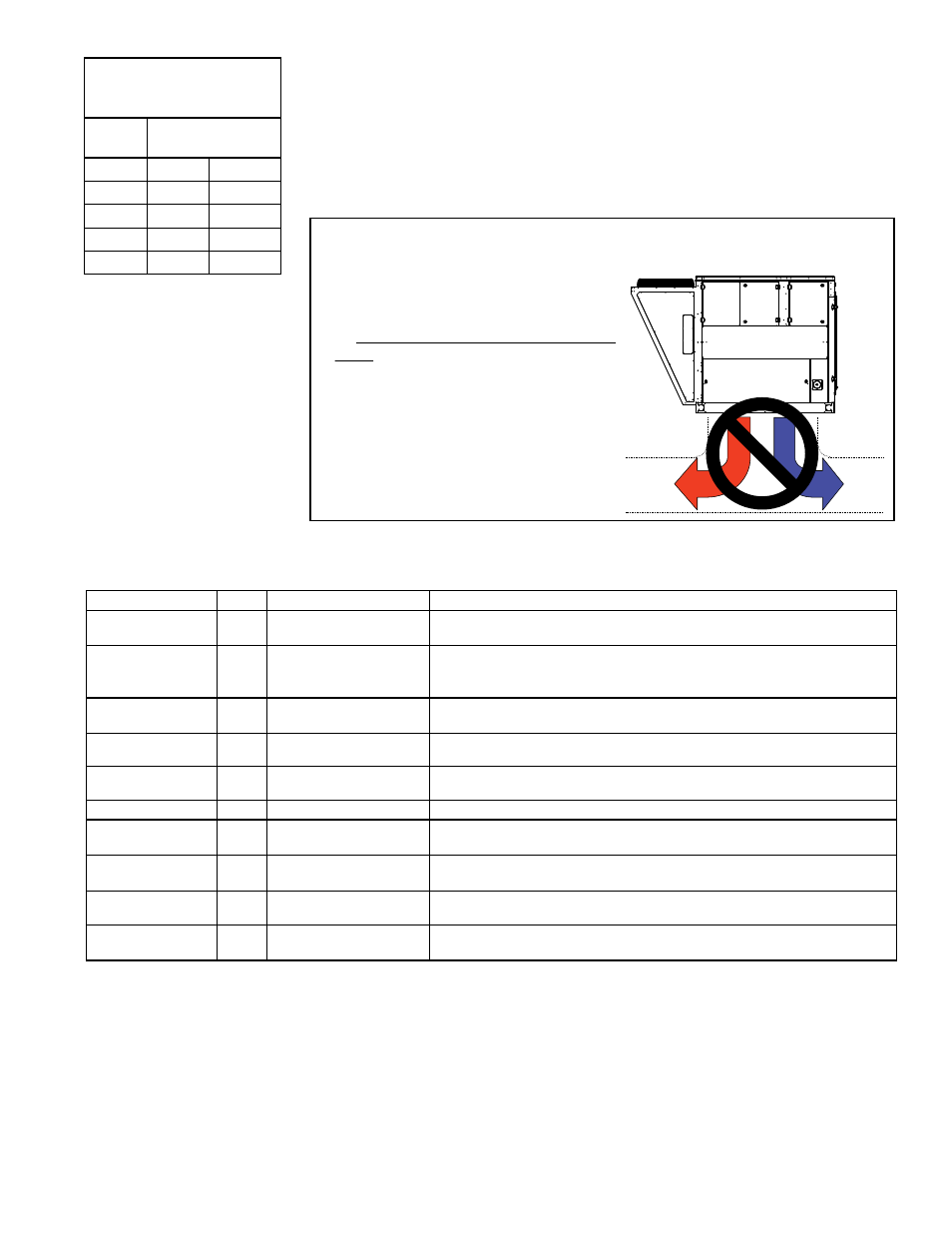

If a Model RECB, REDB, RECC, with multi-stage

control is installed in a system with immediate

“T” configuration ductwork leaving the discharge,

heat staging may allow stratification of the air.

The result is hot air only moving down one

segment of the duct while cool air moves

down the other segment. Avoid this application.

If this application is not avoidable, provide air

mixing devices or the necessary duct length

before the “T” for mixing of the discharge air.

Specific requirements for locating

discharge air sensor on electric heat

models:

FIGURE 27 - Sensor Location for Units with an Electric Heat Section

with Stage Control

sensors, discharge air sensors, etc.) that are connected to the controller be routed

to the unit in one of the following manners:

• In separate field-supplied conduits, isolated from 24 VAC controls and line volt-

age power to the unit,

OR

• If the sensor wires are to be run in the same field-supplied conduit as 24 VAC

control wiring, use shielded cable and bundle wires separately from 24 VAC

control wiring. The shield must be drained at the unit and taped on the opposite

end.

8.1.2 Optional Unit

Monitoring Sensors

In addition to the standard sensors, the unit may be equipped with the following optional

unit monitoring sensors: Most are factory installed but some require field installation.

Follow the sensor wiring requirements above for wiring field-installed sensors.

Senses

Option Components

Installation and Function

Evaporator Coil

Temperature

BE9

Sensor,

P/N 223111

Factory installed sensor to monitor and control the temperature of the air

as it exits from passing through the evaporator coil.

Mixed Air

Temperature

BE10 Sensor,

P/N 223111

Factory installed sensor between the filters and the evaporator coil to

monitor the temperature of the "mixed air" entering from both outside and

through the return air opening.

Duct Static

Pressure

BE11 Transducer, P/N 234818;

sensor port, P/N 234821

Factory installed transducer to monitor duct pressure. Requires field

installation of pickup and tubing in the supply duct. See instructions below.

Building Static

Pressure

BE12 Transducer, P/N 234819 Factory installed transducer to monitor building pressure. Requires field

installation of field-supplied pickup(s) and tubing. See instructions below.

Return Air

Temperature

BE13 Sensor,

P/N 222753

Field installed in the return air duct to monitor the temperature of return air

entering the unit.

Return Air Humidity

BE14 Sensor, P/N 234907

Field installed to monitor the humidity of return air entering the unit.

Space CO

2

, Range

0

to

2000 ppm

BE15 Sensor,

P/N 234820,

Field installed in the building to monitor the carbon dioxide level. See

instructions below and in the sensor manufacturer's form.

Filter Pressure

BE16 Sensor,

P/N 255784

Factory installed photohelic pressure sensor monitors pressure through

the filters and send a signal to the IQ Controller.

Duct Smoke

Detector

BE17 Smoke Detector, P/N

159553

Field installed photohelic smoke detector in the supply ductwork. See

instructions below and in the manufacturer's installation form.

Filter Pressure

BE16 Pressure Switch, P/N

105507

Factory installed pressure switch monitors pressure drop through the

filters and sends signal to I/Q Controller.

Option BE11, Duct Static Pressure Sensor

The differential pressure transducer (

P/N 234818) used in Option BE11 is mounted in

the low voltage compartment. A data sensor port is shipped loose to be attached to

the side of the ductwork. To install the duct sensor port, locate a position about 2/3 the

distance of the duct run (minimum of 10 duct lengths). Drill a hole in the side of the

duct, insert the sensor tube and attach with four sheetmetal screws. The transducer

has a high and a low tubing port. The low tubing port will remain open to measure

atmospheric pressure. Connect 1/4" field-supplied tubing to the high pressure port and

to the field-installed sensor port. The transducer has a range of 0 to 2.5" w.c. and was

calibrated at the factory; it should not need field adjustment. Refer to the manufac-

turer's instructions in the owner's envelope for additional information.

Instructions for Field-

Installed Sensors in

Table above

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual