0 optional equipment (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 58

Form I-MAPSIII&IV, Page 58

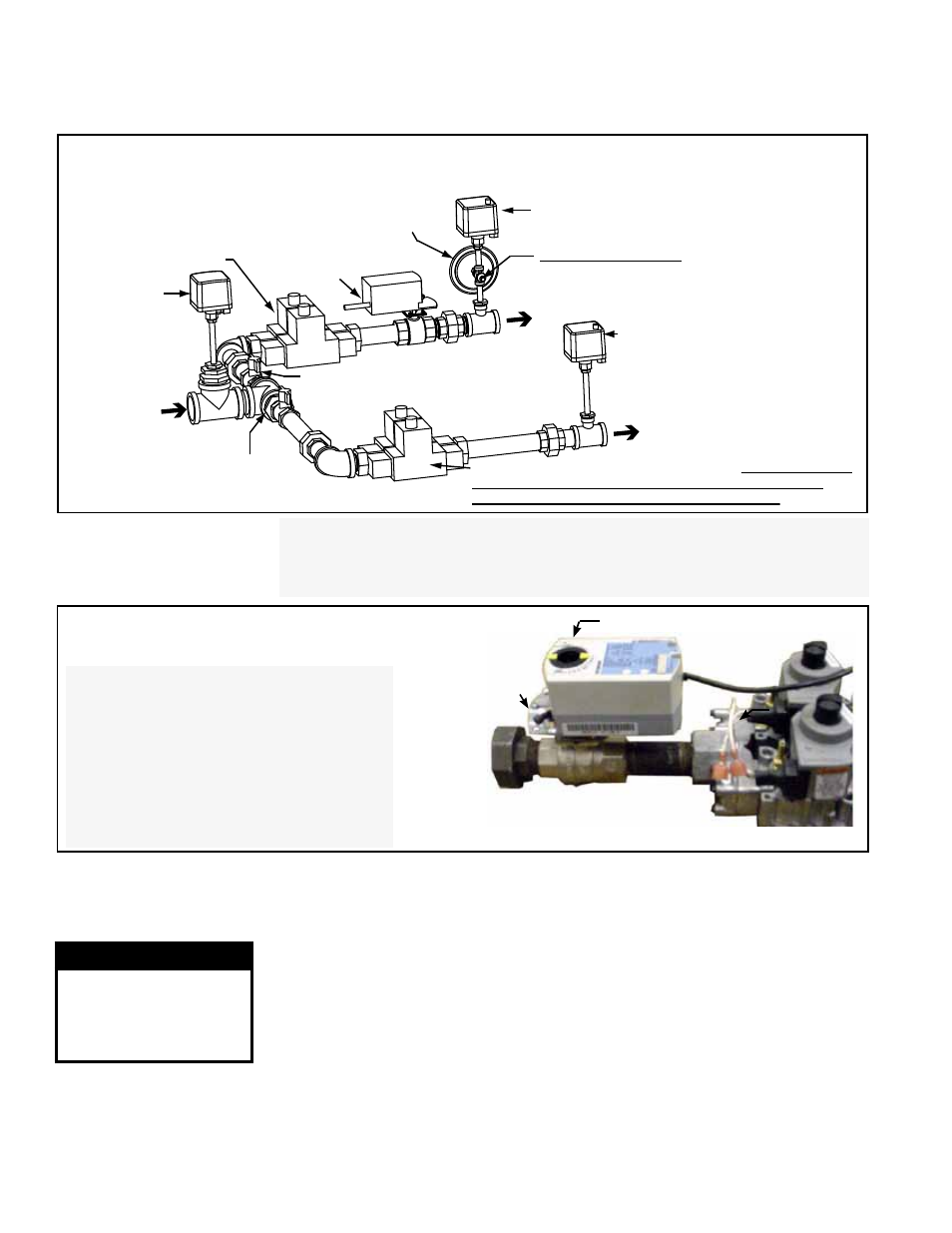

FIGURE 39 - Modulating Gas Control Manifold showing Two Furnaces - D Cabinet Sizes 1000,

1200, 1400, 1600 (See NOTE below.)

Optional Low

Gas Pressure

Switch

Manual Shutoff Valve

(2nd furnace)

Manual Shutoff Valve

(1st furnace)

Dual,

Single-Stage

Gas Valve

(1st furnace)

Dual, Single-Stage Gas Valve (2nd furnace) Measure manifold

pressure at the outlet taps in this valve; see FIGURE 41B,

page 40, and follow instructions beginning below.

Optional High Gas Pressure

Switch (1st furnace)

Manifold Pressure TAP

(1st furnace)

Optional High Gas

Pressure Switch

(2nd furnace)

To burner on

1st furnace

To burner on

2nd furnace

Gas

Supply

Ball Valve

with Actuator

(1st furnace)

(See FIGURE 31.)

Pressure Switch

(1st furnace)

NOTE: "D" Cabinets with Heat section Sizes 500, 600, 700, and 800 with

one furnace have the manifold for "1st furnace" only. "D" Cabinets with

two furnaces (Heat Section Sizes 1000, 1200, 1400, and 1600) have two

manifolds as shown in FIGURE 39.

9.2 Gas Heat - Models RDCB, RDDB, RDCC, RDDC (cont'd)

9.0 Optional

Equipment

(cont'd)

9.2.1.2 Gas Piping and Pressures (cont'd)

9.2.1 Gas Heat Module - Mechanical (cont'd)

FIGURE 40 - Actuator and Ball Valve in

Modulating Gas Control Option AG70

Single-Stage or Dual Single-Stage

Valve

If manifold pressure adjustment is

required, outlet pressure of the single-

stage gas valve (either regular or dual)

must be adjusted. See

FIGURE 41A or

41B and follow instructions for adjusting

the single stage valve

.

Ball Valve Actuator

Setscrew

Ball Valve

Manifold Pressure

Measuring and

Adjustment

The valves are normally set at the factory to provide 3.5" w.c. manifold pressure on a

demand for high fire.

Measuring manifold gas pressure cannot be done until the heat section is in operation.

It is included in the steps of the "Check-Test-Start" procedure in Paragraph 10. The

following warnings and instructions apply.

NOTE: Manifold pressure is checked at high fire. If the heat section has two furnaces,

measure manifold pressure of both furnaces at the same time.

WARNING

Manifold gas

pressure must never

exceed 3.5" w.c. for

natural gas.

CAUTION: DO NOT bottom out the gas valve regulator adjusting

screw. This can result in unregulated manifold pressure causing

excess overfire and heat exchanger failure.

Instructions for Measuring High Fire Manifold Pressure (can only be

done after the heater is operating)

1) Turn the manual valve in the gas line off. Locate the tap(s) for testing pressure.

See

FIGURES 38 A, B, C or 39.)

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual