0 optional equipment (cont'd), 1 inlet air options (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 54

Form I-MAPSIII&IV, Page 54

NOTE: To verify control

option selection, check the

option listing on the wiring

diagram and the option list

in the

APPENDIX, page 73.

Damper Linkage

Outside Air & Return Air Dampers, Option AR25, AR2G, AR2H, or

AR2K

- If outside and return air motorized dampers were ordered, there are a variety

of damper control options (Option GF). Some require field installation. If the damper

control sensing option requires field installation of components, the components are

shipped with the unit and include the manufacturer's instructions. Install according to

the instructions and connect the wires according to the unit diagram. Follow the same

wiring recommendations as in Paragraph 8.1.1 for the discharge air temperature sen-

sor.

When a system has both an outside air and a return air damper, both dampers are

closed for shipping. The linkage of the return air damper must be adjusted prior to use.

Follow instructions to adjust damper linkage.

1. Open the damper access door.

2. Loosen the setscrew on the return air damper rod at the damper arm.

3. Manually open the return air dampers. While the dampers are opening, the

damper rod and arm will automatically move to its correct position.

4. Tighten the setscrew.

5. Close the door.

9.0 Optional

Equipment

(cont'd)

9.1 Inlet Air Options (cont'd)

Senses

Option

Parts

Installation and Function

Remote Damper Control,

DDC

GF1 (requires

BHB6 Board)

Damper position is adjusted by the IQ controller in response to a field-

supplied remote 0-5V input signal. The I/Q controller limits the drive

speed between 25% to 100%.

Two Position Damper

Control (open/closed), DDC

GF2

Sends message to open or close dampers as required. Damper

opens to a fixed setpoint during occupied mode and closes during

unoccupied mode.

Four-Position Damper

Control

GF4 (requires

BHB6 Board)

Factory installed to provide four damper settings from two switches.

Each input represents a position. As the input changes, the I/Q

controller changes the damper position

Building Static Pressure

GF5 (requires

BHB6 Board)

Sensor, P/N

234819

Factory installed to monitor building pressure for damper operation.

Requires field-installation of sensor. See instructions below.

Mixed Air Controlled by

CO2 level

GF6 (requires

BHB6 Board)

Sensor, P/N

234820

Field installed in the building to monitor the carbon dioxide level. See

instructions below and in the sensor manufacturer's installation form

Outside Air Damper, 2-

Position Enthalpy Control

GF7

Factory installed to monitor the humidity of outside air entering the

unit.

Mixed Air Dampers, Dual

Reference Enthalpy Control

GF8 (requires

BHB6 Board

P/N 234907 Factory installed to measure enthalpy and provide information for

control of outside and return dampers.

Dry Bulb Mixed Air

Economizer

GF9

P/N 222753

and 223111

Factory installed to measure dry bulb temperature and provide

information for control of outside and return dampers.

Damper Control Options

Instructions for Field-

Installed Sensors in

Table Above

Option GF5, Building Static Pressure Sensor

The differential pressure transducer (

P/N 234819) used in Option GF5 is mounted in

the low voltage compartment. The transducer has a high and a low tubing port. The

low tubing port will remain open to measure atmospheric pressure. Connect 1/4" field-

supplied tubing to the high pressure port and run it to a common area in the building.

Cut the end of the tubing at a 45° angle to minimize the affect of air movement and

attach it to a wall or in a ceiling. The transducer has a range of 0 to .5" w.c. and was

calibrated at the factory; it should not need field adjustment.

Refer to the manufacturer's instructions in the owner's envelope for additional informa-

tion.

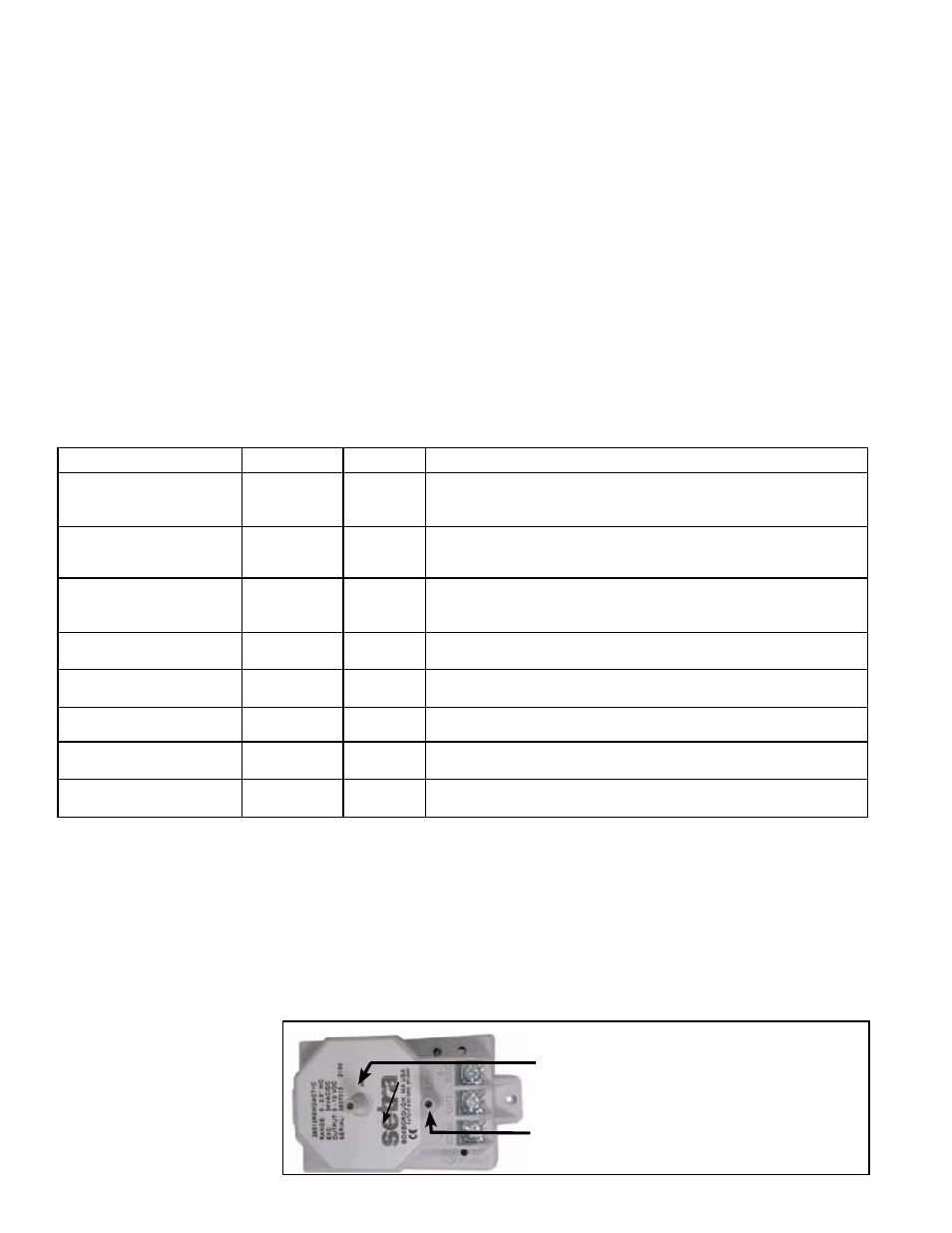

FIGURE 35A -

Electrical Connections

and Tubing Ports on

Option GF5, Building

Static Pressure Sensor

High Pressure Port - Attach tubing.

Low Pressure Port - Leave open.

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual