Optional equipment (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 62

Form I-MAPSIII&IV, Page 62

9. Optional

Equipment

(cont'd)

9.2.2 Gas Heat Module Ignition Systems (cont'd)

9.2 Gas Heat -

Models RDCB,

RDDB, RDCC,

RDDC (cont'd)

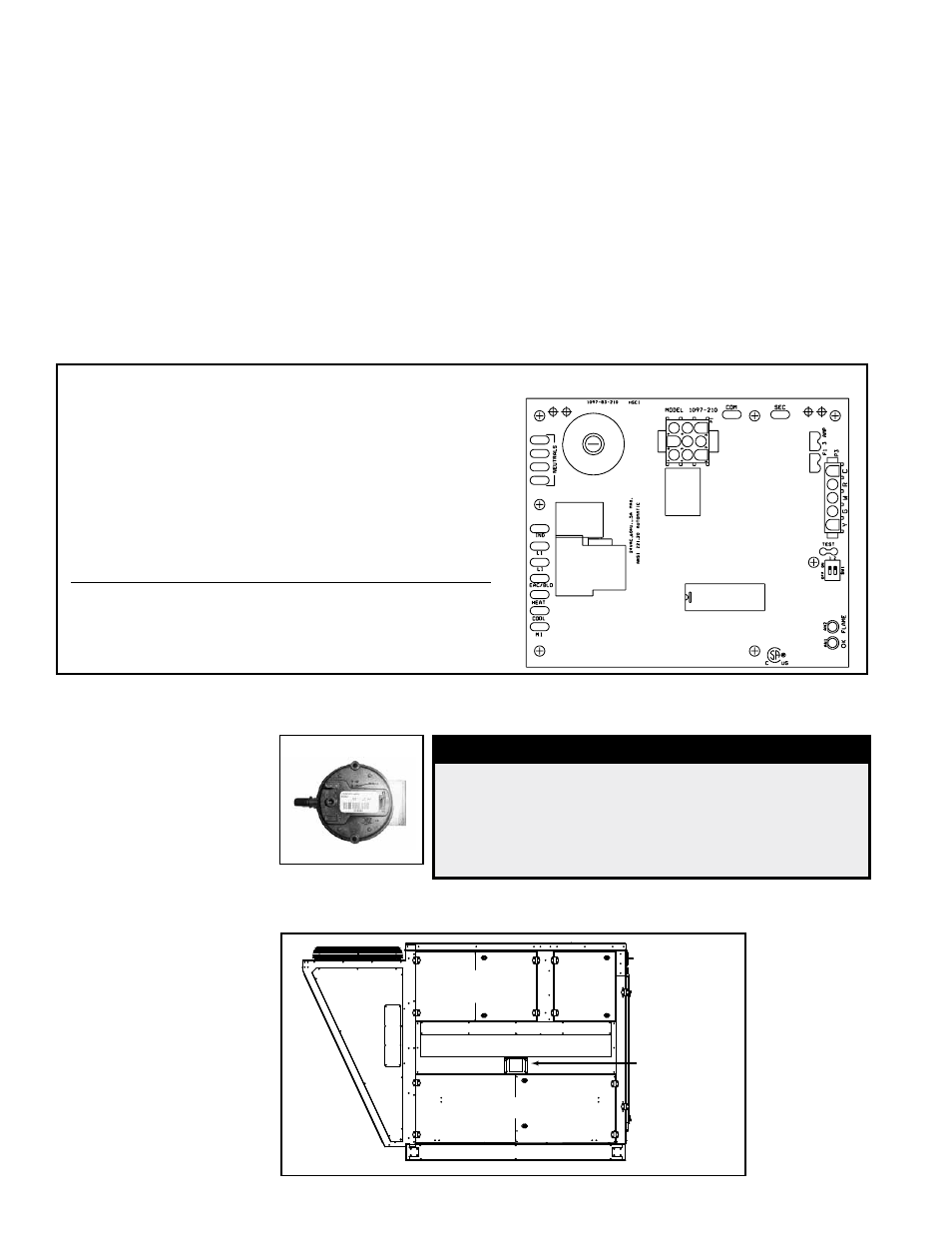

FIGURE 43B – DSI Integrated Control Module on Downstream Furnace - "D" Cabinet only

Spark

Transformer

Control

Plug

Fuse

Thermostat

Connections

Status

Lights

x

Control Status - Green LED Codes

Steady ON ......Normal Operation, No call for heat

Fast Flash .......Normal Operation, Call for heat

1 Flash ............System Lockout, Failed to detect or sustain flame

2 Flashes ........Pressure switch did not close within 30 seconds of

venter motor

3 Flashes ........High limit switch open

4 Flashes ........Pressure switch is closed before venter motor is

energized

Steady OFF ....Blown Fuse, No Power, or Defective Board

Flame Status - Yellow LED Codes

Steady ON ......Flame is sensed

Slow Flash ......Weak flame (current below 1.0 microamps ±50%)

Fast Flash .......Undesired Flame (valve open and no call for heat)

9.2.3 Venting and

Combustion Air

FIGURE 45 - Heat

Section Showing

Location of Flue

Exhaust (vent) and

Combustion Air Hood

- Cabinet A, B, and C

Sizes

Tubing

Access

Control

Panel

Combustion Air Intake Panel

Compressor

Access

Gas Heat Section

Screened

Flue

(Vent)

Outlet

The gas heat section is power vented. Presence of combustion air pressure is moni-

tored by a combustion air proving switch.

2) Prepurge - The circuit board energizes the venter motor and waits for the pressure

switch to close. When the pressure switch is proven closed, the circuit board begins

the prepurge time. The ignition system circuit board runs the venter motor for a 30

second prepurge time, then proceeds to the ignition trial period.

3) Ignition Trial Period - The ignition system circuit board energizes the spark and

main gas valve. The venter remains energized. If flame is sensed at the burner during

the first 6 seconds, the spark is de-energized. The circuit board proceeds to steady

heat.

4) Steady Heat - Circuit board inputs are continuously monitored to ensure limit and

pressure switches are closed, flame is established, and the system controller call for

heat remains. When the call for heat is removed, the ignition system circuit board de-

energizes the gas valve and begins postpurge timing.

5) Post Purge - The venter motor output remains on for a 45-second postpurge period

after the system controller is satisfied.

FIGURE 44 -

Combustion Air

Proving Switch

DANGER

Safe operation requires proper venting flow.

Never bypass the combustion air proving switch

or attempt to operate the heat section without

the venter running and proper flow in the vent

system. Hazardous condition could result.

9.2.3.1 Venting and

Combustion Air -

MAPS

®

Cabinets A, B,

and C

The combustion air inlet hood is located on the side of the unit near the compressor

compartment. See

FIGURE 45. The flue outlet is also located on this side.

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual