0 mounting (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 20

Form I-MAPSIII&IV, Page 20

Assembly and Installation Instructions for Option CJ54 & CJ53, Curbs

with Energy Recovery Module (cont'd)

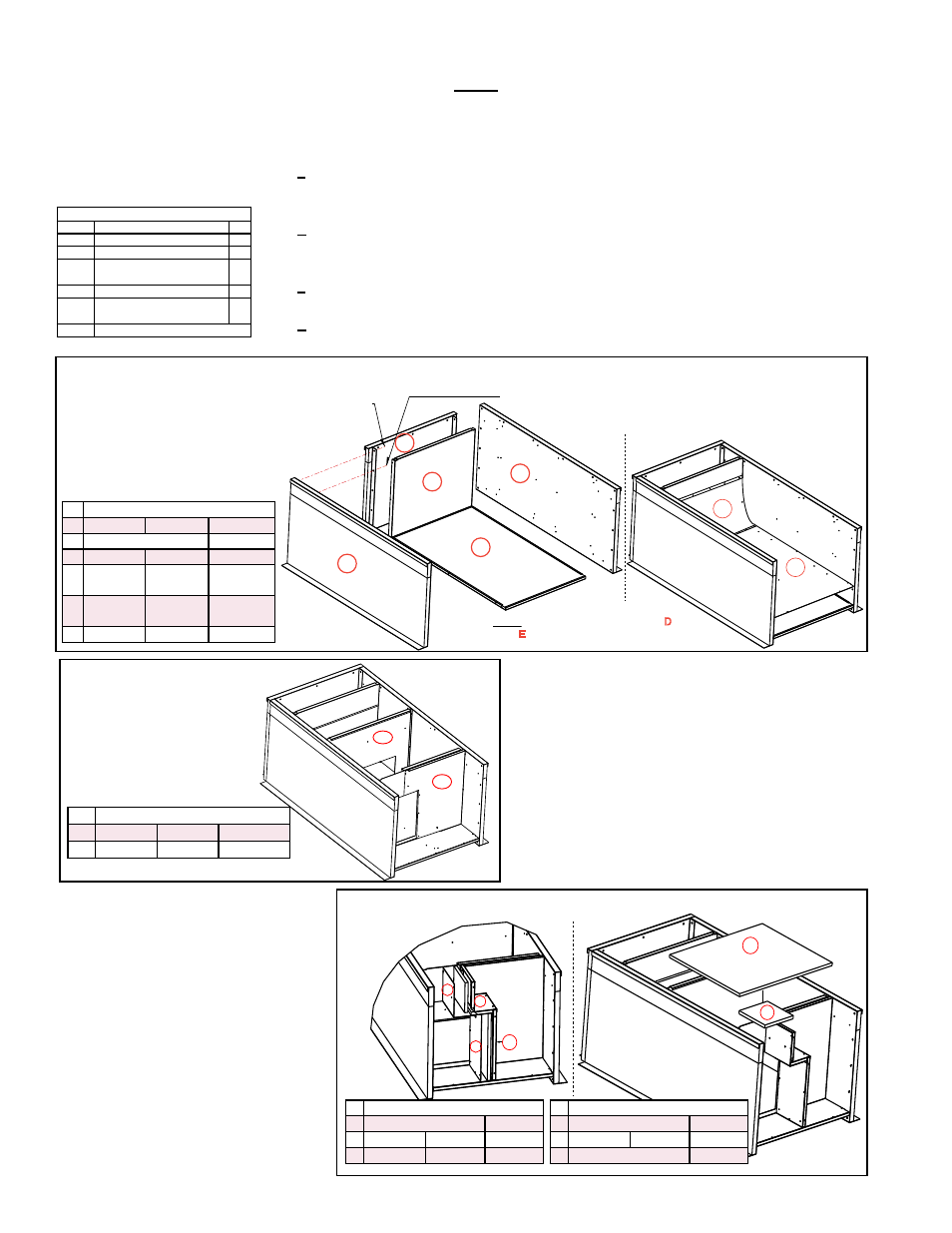

FIGURE 10A - Assemble Curb End (

A

), Curb Sides (

B&B

), Supply Duct End (

C

), Insulated Bottom

(

D

) Bottom Liner (

E

)

and Baffle (

F

)

FIGURE 10B - Install

Duct Partitions

G1

and

G2

Insulation NOTE: There is no

exposed insulation in the ducts.

All insulation in airflow paths is

covered with a liner.

FIGURE 10C - Install Smaller Duct Partitions, Liners, and Tops

5.0 Mounting

(cont'd)

5.4.2.2 Roof Curbs for Horizontal Airflow (Options CJ54 & CJ53) for

Cabinets A, B, and C WITH an Energy Recovery Module (cont'd)

5.4.2 Roof Curbs for

Horizontal Airflow

- Cabinets A, B, C

(cont'd)

A

B

B

C

D

E

B

B

D

A

C

(8 per corner) 3/4” Hex Head Cap Screws

with Lockwashers and Hex Nuts

2” Lag Screw

& Lockwasher

(1 per corner)

NOTE: Cabinet C - insulated bottom (D) and

liner (E) are both two pieces.

(insulation up)

(liner)

F

4. Install supply air duct partition (

Code G1

) and

return air duct partition (

Code

G2

) with sheet-

metal screws (

FIGURE 10B).

a) Position partition (

Code

G1

) in the orientation

illustrated. Align the holes and attach the

partition to curb sides (

B & B) and bottom liner

(

E).

b) Position partition (

Code

G2

) in the orientation

illustrated. Align the holes and attach the

partition to curb sides (

B & B) and bottom liner

(

E).

A

B

B

C

E

G1

G2

F

K

J

H

L

B

B

G2

E

G1

M

N

(Insulation

side up)

B

G2

B

L

E

A

C

G1

K

F

5. Install supply air and return air

insulated duct dividers (

Codes H

& J

)

; divider liners (

Codes K & L

);

and duct tops (

Codes M & N

) using

sheetmetal screws (

FIGURE 10C).

a) Position and attach duct dividers

(

Codes H & J

) as illustrated.

Cover the insulation with liners

(

Codes K & L

) and attach with

screws.

b) Position tops (

Codes M & N

)

with insulation side up. Align

the holes (push the insulation

out of the way) and attach the

perimeter.

Hardware Bag includes:

P/N Description

Qty

1035 Nut 5/16" Hex-18 Thread

48

1333 Lockwasher 5/16 In.

60

16243 Hex Hd Lag Bolt 5/16" x

1-1/4"

12

16247 Cap Screw 5/16 x 3/4"

48

11813 S/M Screw #10-16x1/2 Ab

Stalgd

210

66302 1-1/4 x 1/4 x 50 ft Sealant Tape

ID

P/N by Cabinet Size

A

A-261653 B-261654 C-261670

B

A&B-261655

C-261671

C

A-261658 B-261659 C-261673

D

A-261660 B-261661 C-261674

& 261428

E

A-261394 B-261395 C-261418

& 261429

F

A-268604 B-268605 C-268606

ID

P/N by Cabinet Size

G1

A-261396 B-261663 C-261419

G2

A-261662 B-261663 C-261675

ID

P/N by Cabinet Size

H

A&B - 261666

C-261677

J A-261667 B-261668 C-261678

K A-261408 B-261409 C-261426

ID

P/N by Cabinet Size

L

A&B-261405

C-261424

M A-261664 B-261665 C-261676

N

A&B-261669

C-261679

3. Install supply duct end (

Code

C

) and bottom (

Codes D &

E

).

a) Position the solid partition (

Code C

) with insulation side toward the solid end of

the curb. Align the holes (push the insulation out of the way) and attach partition

to curb sides (

B & B).

b) Position the duct bottom (

Code

D

) in the curb with insulation side up. Align the

holes (push the insulation out of the way) and attach partition to curb sides (

B &

B). Attach the bottom (

Code

D

) to the partition (

C).

c) Position the bottom liner (

Code

E

) over the insulation in the bottom of the curb.

Align the holes and attach around the perimeter.

d) Position the air baffle (

Code F

) against the partition (

C). Align the holes and

attach. Align the air baffle with the holes in the bottom liner (

E) and attach.

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual