0 controls, 1 cooling/dehumidification/heating control . 45, 1 cooling/dehumidification/heating control – Reznor RECC Unit Installation Manual User Manual

Page 45

Form I-MAPSIII&IV, P/N 222917R9, Page 45

FIGURE 23 - Optional

Hot Gas Bypass Valve

Check Hot Gas Bypass Valve Setting - On the circuit with a hot gas bypass valve,

connect a pressure gauge to the suction line and block the entering air to the evapora-

tor coil. Suction pressure will drop, and the hot gas bypass valve should begin to open

at approximately 115 psi and will be fully open at 95 psi. When the valve begins to

open, it will be hot to the touch (see caution below).

CAUTION: Do not touch the hot gas bypass valve when

operating. Use caution when checking and adjusting the

valve. Wear appropriate safety gear.

If pressure needs to be adjusted, remove the cap and turn the adjusting stem clock-

wise to increase the pressure setting or counterclockwise to decrease the pressure

setting. Make adjustments in small increments. Allow five minutes between adjust-

ments for the system to stabilize. When finished, replace the cap on the adjustment

stem and remove the pressure gauge.

Modulating Reheat,

Option AUR1

With modulating reheat, a sensor monitors the air temperature as it leaves the reheat

coil. Based on a potentiometer setpoint and the sensor signal, the board will open or

close a refrigerant bypass valve. Changing the amount of refrigerant hot gas being

added to the refrigerant liquid before it enters the pre-cool coil will “modulate” the func-

tion of the pre-cool and reheat coils to provide the desired leaving air temperature.

8.0 Controls

NOTE: See control details and instructions in

Form CP-MAPS-D15/D16 included with the unit and

available at www.RezSpec.com.

All systems have a unit-mounted, IQ controller that is pro-

grammed to control cooling, dehumidification, and/or heating

based on discharge air temperature, outdoor air temperature,

dewpoint, and/or enthalpy depending on which Model and

options were ordered. The system control option is identified

as either Option D15, programmed for neutral air/discharge

air control, or Option D16, programmed for space control with

discharge air reset.

The integrated LCD display (*BACview) will show the current

discharge air temperature, outdoor air temperature, dewpoint,

and enthalpy; which outputs are enabled; and the mode of

operation. The control allows the user to change setpoints,

change prop bands, and adjust the time clock.

Control Option D16 will also have a wall temperature sensor.

If ordered as Option CL77 with Option D15, it will also have a

wall temperature sensor. Or, if ordered with Option RB4, there

is a handheld display/control module with most of the same

functions as the unit-mounted display.

A brief description of control functions follows in this section.

For additional information and to make adjustments, see the

more detailed control instructions in Form CP-MAPS D15/

D16.

The IQ controller has an integral time clock for occupied/unoc-

cupied modes and supports BACnet (over MSTP or ARCnet)

and LonWorks protocols. The control also provides or moni-

tors the air proving switch, low limit protection, anti-cycle pro-

tection, minimum on/off times, phase loss protection, optional

dirty filter sensor, gas valve modulation on systems with a gas

heat section, and electric staging on systems with electric

heat.

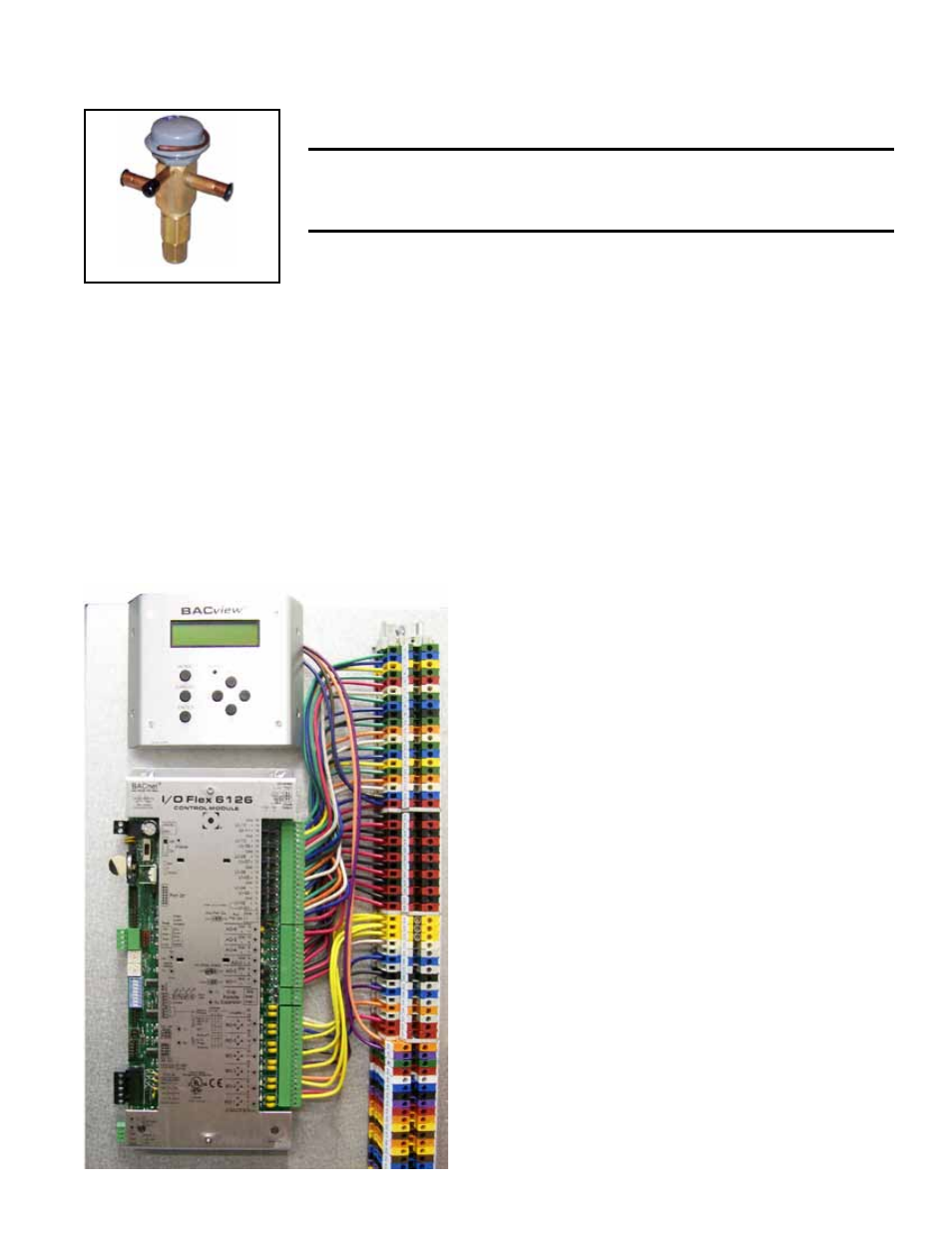

8.1 Cooling/Dehumidification/Heating Control

FIGURE 24 - Controller and BacView

Display in Electrical Compartment

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual