5 condensate drains, 0 mechanical (cont'd), Ba a/2 – Reznor RECC Unit Installation Manual User Manual

Page 38: Lunit, 4 duct connections and ductwork (cont'd)

Form I-MAPSIII&IV, Page 38

All systems require a condensate drain on the cooling section and all "D" cabinet mod-

els with gas heat require a drain on the heat section.

ALL Models - A slide-out, removable drain pan with a 1 or 1-1/2" male NPT

condensate drain connection is located below the coil cabinet. When connecting

the drain line, provide a means of disconnecting the line at or near the cabinet

connection to allow the drain pan to be removed for cleaning.

D Cabinet Models RDDB and RDCB - Below the gas heat section that is closest

to the blower, there is 1/2" male NPT connection for a condensate drain line.

Follow the instructions below to install a trap in each drain.

Do not reduce the drain

diameter. Pitch the drain line at least 1/2" (13mm) for every 10 feet (3M) of horizontal

run. Drain lines must not interfere with drain pan or access panels.

An obstruction in the drain or a poorly designed drain can cause the condensate pan to

over flow. Overflow could result in damage to the unit and/or the building.

If the installation or local code requires, run drain into a waste water system.

6.5 Condensate

Drains

NOTE: Do not reduce

the diameter of the

condensate drain

piping.

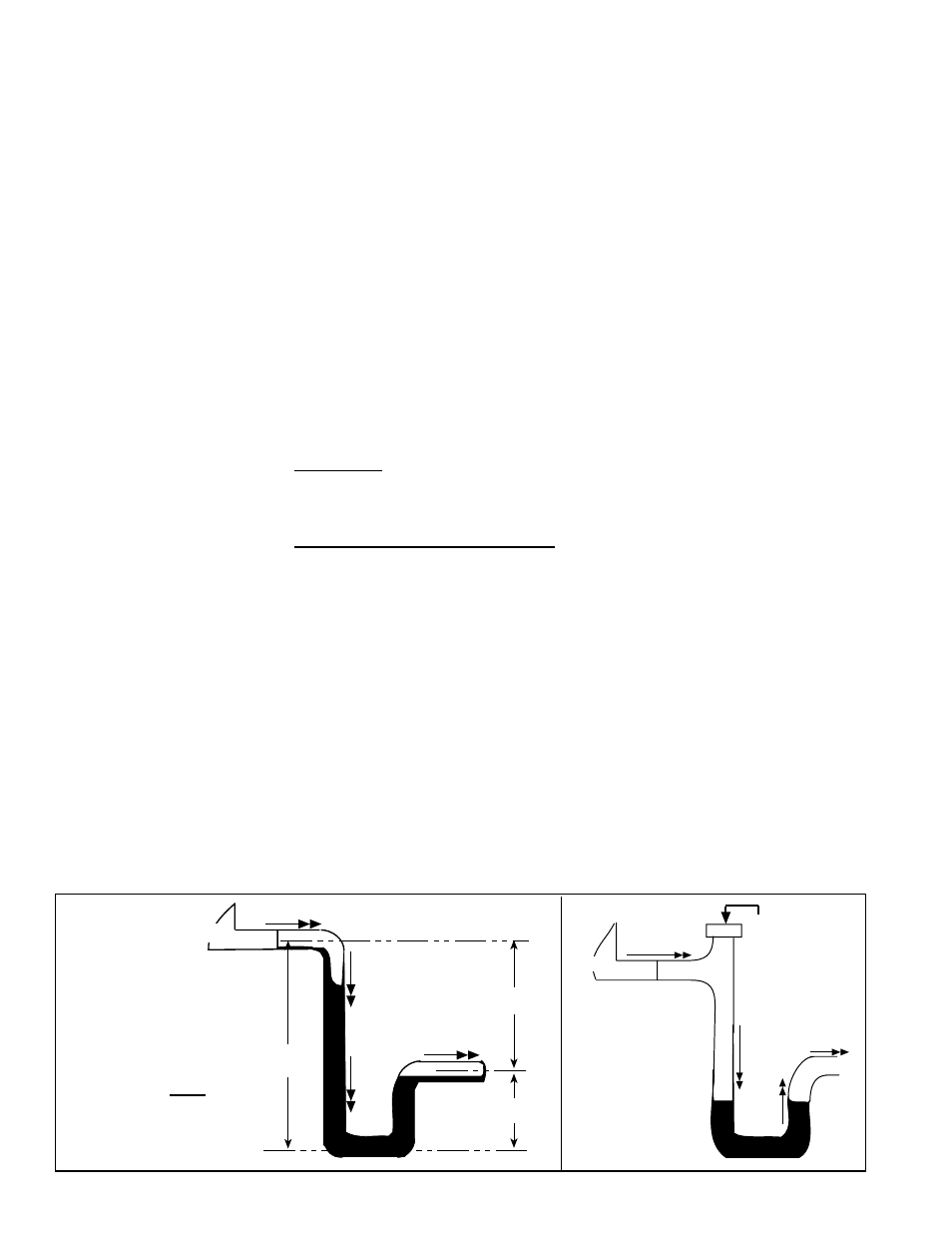

The design of the drain trap is important. Since the condensate drain pan is on the

blower inlet side, there is a negative pressure at the drain relative to the ambient. The

trap height must account for this static pressure difference. Maximum negative static

can be determined by reading the negative pressure at the blower inlet and adding .2”

w.c. to allow for dirty filters.

If dimension "B" in

FIGURE 19A is not tall enough, the water seal will not hold, and air

will be drawn through the drain pipe into the system. If the outlet leg of the trap is too

tall, water will back up into the drain pan. As condensate forms during normal opera-

tion, the water level in the trap rises until there is a constant outflow.

FIGURE 19A

illustrates the appropriate dimensions for trapping a negative pressure system.

Condensate Drain Trap

6.0 Mechanical

(cont'd)

To prevent air

from entering

always close

the cleanout.

Water Flow

Unit

FIGURE 19B -

Drain Trap with

Cleanout

B

A

A/2

C

L

C

L

C

L

Unit

Water Flow

Water Flow

A = 1" (25mm) for

each 1" (25mm) of

maximum static

pressure plus 1"

(25mm)

B = A + A/2

FIGURE 19A -

Condensate

Drain Trap

Dimensions

• Through Masonry Walls - No supply air duct should come in contact with

masonry walls. Insulate around all air ducts through masonry walls with not less

than 1/2" (13mm) of insulation. 1" (25mm) is recommended.

• Through Uncooled/Unheated Space - Insulate all exposed supply air ducts

passing through an uncooled or unheated space with at least 1/2" (1" is

recommended) of insulation.

• Duct Supports - Suspend all ducts securely from buildings members. Do not

support ducts solely by the unit duct connections.

• Duct Sizing - Proper sizing of the supply air ductwork is necessary to ensure a

satisfactory installation. The recognized authority for such information is the Air

Conditioning Contractors Association, 2800 Shirlington Road, Suite 300, Arlington,

VA 22206 (www.acca.org). A manual covering duct sizing in detail may be

purchased directly from them.

• Duct Connections - To minimize sound and vibration transmission, use

flexible duct connections. Ducts must be attached and sealed to provide airtight

connections.

• Return Air Duct/Grill Size - Make certain that return air ducting or grill has a free

area equal to the return duct size connection.

6.4 Duct

Connections

and Ductwork

(cont'd)

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual