0 controls (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 50

Form I-MAPSIII&IV, Page 50

Senses

Option Components

Installation and Function

External DDC Controller, 0-5V

VFC2

Requires a field supplied input source.

Duct Static Pressure (0 to 2.5"

w.c.)

VFC3

Transducer, P/N

234818; Probe

P/N 234821

Factory installed to monitor duct pressure. Requires field installation

of sensor in the supply duct. See instructions below and in the

sensor manufacturer's installation form.

Building Static Pressure

(-0.5 to 0.5" w.c.)

VFC4

Transducer, P/N

234819

Field installed sensor to monitor building pressure. Requires field

installation of tubing and sensor. See instructions below and in the

sensor manufacturer's installation form.

CO2 Sensor (0-2000 ppm)

VFC5

P/N 234820

Field installed in the building to monitor the carbon dioxide level. See

instructions below and in the sensor manufacturer's instructions.

Wall Stat for Low/Medium/High

Speed Control

VFC7

Requires CL77

wall sensor.

Wall temperature sensor, P/N 222756, must be installed. See the

wiring connections below and on the unit wiring diagram.

Four speed fan control

VFC8

Factory installed relay. Two hardware inputs and four setpoints

provide 4-speed control through IQ controller.

Adjustable Constant Volume

Control

VFC9

Adjustable constant speed controlled by the IQ controller through an

adjustable setpoint.

8.0 Controls

(cont'd)

Sensors for Optional Variable Frequency Drive

8.1.2 Optional Unit Monitoring Sensors (cont'd)

8.1 Cooling/ Dehumidification/Heating Control (cont'd)

Field-installed Sensors

for VFC Options.

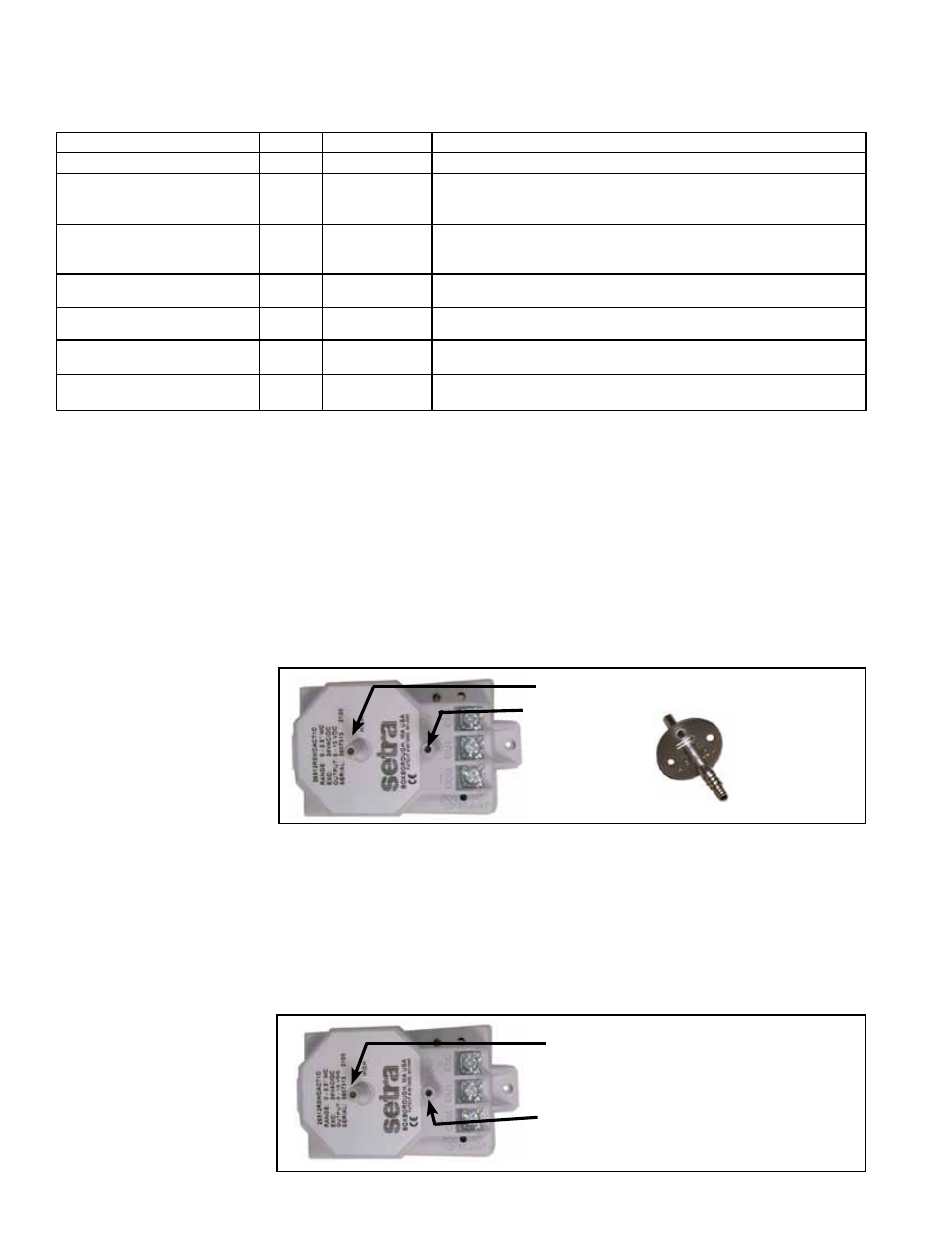

Option VFC3, Duct Static Pressure Sensor

The differential pressure transducer (

P/N 234818) is mounted in the low voltage com-

partment. A data sensor pickup is shipped loose to be attached to the side of the duct-

work. To install the duct sensor port, locate a position about 2/3 the distance of the duct

run (minimum of 10 duct lengths). Drill a hole in the side of the duct, insert the sensor

tube and attach with sheetmetal screws. The transducer has a high and a low tubing

port. In most installations, the low tubing port will be sensing atmospheric pressure so it

can be left open. If a different reference point is needed, attach 1/4" tubing and extend

to that location. Connect 1/4" field-supplied tubing to the high pressure port and to the

field-installed sensor port. The transducer has a range of 0 to 2.5" w.c. and was cali-

brated at the factory; it should not need field adjustment. Refer to the manufacturer's

instructions in the owner's envelope for additional information.

FIGURE 29A -

Tubing Ports on the

Transducer in Option

VFC3 and Ductwork

Sensor Port

High Pressure Port - Attach tubing.

Low Pressure

Port -

Leave open.

or attach

tubing.

High Pressure

Data Sensor Port

- Attach to duct-

work. Slide tubing

on barb.

Option VFC4, Building

Static Pressure Sensor

FIGURE 29B -

Electrical Connections

and Tubing Ports on

Option VFC4, Building

Static Pressure Sensor

High Pressure Port - Connect to the

high pressure reference point.

Low Pressure Port - Connect to the

low pressure reference point.

The differential pressure transducer (

P/N 234819) used in Option VFC4 is mounted

in the low voltage compartment. The transducer has a high and a low tubing port.

Depending on the application, attach tubing to both ports or leave one open to atmo-

spheric pressure. Connect 1/4" field-supplied tubing to the port(s) and run it to the

pressure reference point(s). Cut the end of the tubing at a 45° angle to minimize the

affect of air movement and attach it to a wall or in a ceiling. The transducer has a range

of -0.5 to .5" w.c. and was calibrated at the factory; it should not need field adjustment.

Refer to the manufacturer's instructions in the owner's envelope for additional informa-

tion.

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual