0 mounting (cont'd), 4 mounting on a roof curb (cont'd), Duct furnace operation – Reznor RECC Unit Installation Manual User Manual

Page 24: Option jh30 duct furnace installation, Remote temperature controller, Form i-mapsiii&iv, page 24

Form I-MAPSIII&IV, Page 24

5.0 Mounting

(cont'd)

5.4.3 Duct Furnace Curb Sections, Option JH30 for Cabinet C and

Option JH25 for Cabinet B (cont'd)

Duct Furnace Operation

The duct furnace can only be energized after the main unit DSI control has enabled

operation of the integral heat section and the remote temperature controller's sensor

initiates a call for heat. When both of these conditions are met, the duct furnace will

be energized to operate at full fire only.

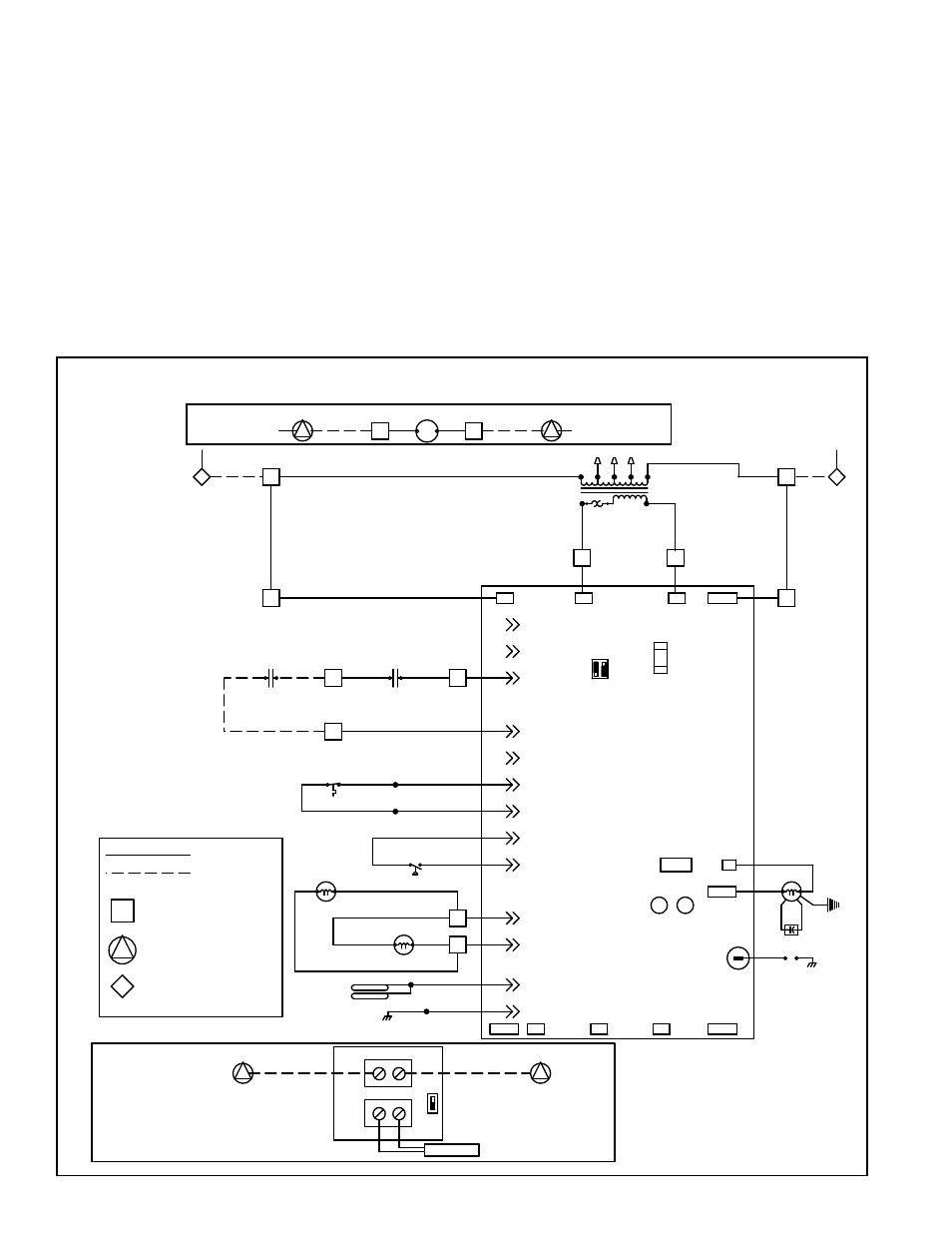

FIGURE 11C - Wiring Connections for Optional Curb Duct Furnace

41

FLAME

ELECTRODES

BR

BK OR R

FLAME GROUND

R

R

BR

R

NEUTRAL

P1-7

P1-9

BL

#2 GAS VALVE

BR

PRESSURE SWITCH

(PS3)

Y

Y

Y

R

P1-4

BL

64

63

BR P1-2

P1-5

P1-3

P1-6

REMOTE TEMPERATURE CONTROLLER

CONTROL TERMINAL IN T7079

DUCT FURNACE ENABLE

RELAY CONTACTS

BK OR R

NO

COM

J4

LIMIT CONTROL

34 R

R

33 R

4

6

R

Y

R

P3-1

P1-8

P3-4

32 Y

P3-2

P3-3

P3-5

DUCT FURNACE ENABLE

RELAY COIL (319)

40

40 BL

7

300

CR

8

BR

41

INTERNAL CONTROL FAULT OR NO POWER

STEADY OFF

(VM2)

MOTOR

VENTER

CAPACITOR

UNDESIRED FLAME (VALVE OPEN & NO CALL FOR HEAT)

(DS2)

WEAK FLAME

FLAME SENSED

DSI CONTROL

DUCT FURNACE

FAST FLASH

SLOW FLASH

STEADY ON

YELLOW LED

OK

LED

G

TRANSFORMER

SPARK

Y

LED

FLAME

TEST

NEUTRAL

IND

BR/W

SPARK GAP

BK

W

BR

BK

G

GRD

NORMAL OPERATION CALL FOR HEAT

NORMAL OPERATION NO CALL FOR HEAT

PRESSURE SWITCH DOES NOT CLOSE WITHIN 30

PRESSURE SWITCH IS CLOSED BEFORE VENTER IS

ENERGIZED

IN LOCKOUT FROM FAILED IGNITIONS OR FLAME LOSSES

SW1

LED FLASH CODES

LIMIT SWITCH OPEN

SECONDS OF VENTER ENERGIZED

2 FLASH

1 FLASH

3 FLASH

FAST FLASH

STEADY ON

4 FLASH

Y

R

C

W

G

GREEN LED

3.0 AMP

FUSE

AT

O

OR A

TC

SEC

COM

NEUTRAL

L1

BREAKER

96

Y

CIRCUIT

88

BK

W

(TX5)

97

Y/W

Y/W

24 V

TRANSFORMER

240V

O

GY

R

75 VA

DSI

O

89

BK

L1

L1

L1

SEC

NEUTRAL

COM

W

BL

BR

89

88

BK

BK

88

89

FACTORY WIRING

FIELD WIRING

TERMINAL BLOCK -- DUCT FURNACE

TERMINAL BLOCK -- HIGH VOLTAGE

TERMINAL BLOCK -- LOW VOLTAGE

COMPARTMENT

COMPARTMENT

(See below and unit diagram.)

#1 GAS VALVE

BL

BL

BR

(See unit wiring diagram.)

(See unit wiring diagram.)

SET ST1 SWITCH

TO HEAT POSITION

(MOUNT IN OUTSIDE AIRSTREAM)

TEMPERATURE SENSOR

T7079 REMOTE

TEMPERATURE

CONTROLLER

J1 SENSOR

J2

24VAC

ST1

21

20

Remote

Temperature

Controller

5.4 Mounting on a Roof Curb (cont'd)

The duct furnace requires a separate gas line; gas connection is 1/2". See gas sup-

ply entrance location in

the illustrations. Refer to Paragraph 9.2.1.2 for gas supply

piping and pressure requirements. The Size 300 duct furnace burner operates only at

high fire. Manifold pressure is 3.5" w.c.; see Paragraph 9.2. The high temperature limit

control functions the same as described in Paragraph 9.2.4.

Field wiring is required. Check the wiring diagram for requirements. Follow the wiring

diagram in

FIGURE 11C to connect the field-supplied wiring.

Option JH30 Duct

Furnace Installation

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual