0 controls (cont'd) – Reznor RECC Unit Installation Manual User Manual

Page 48

Form I-MAPSIII&IV, Page 48

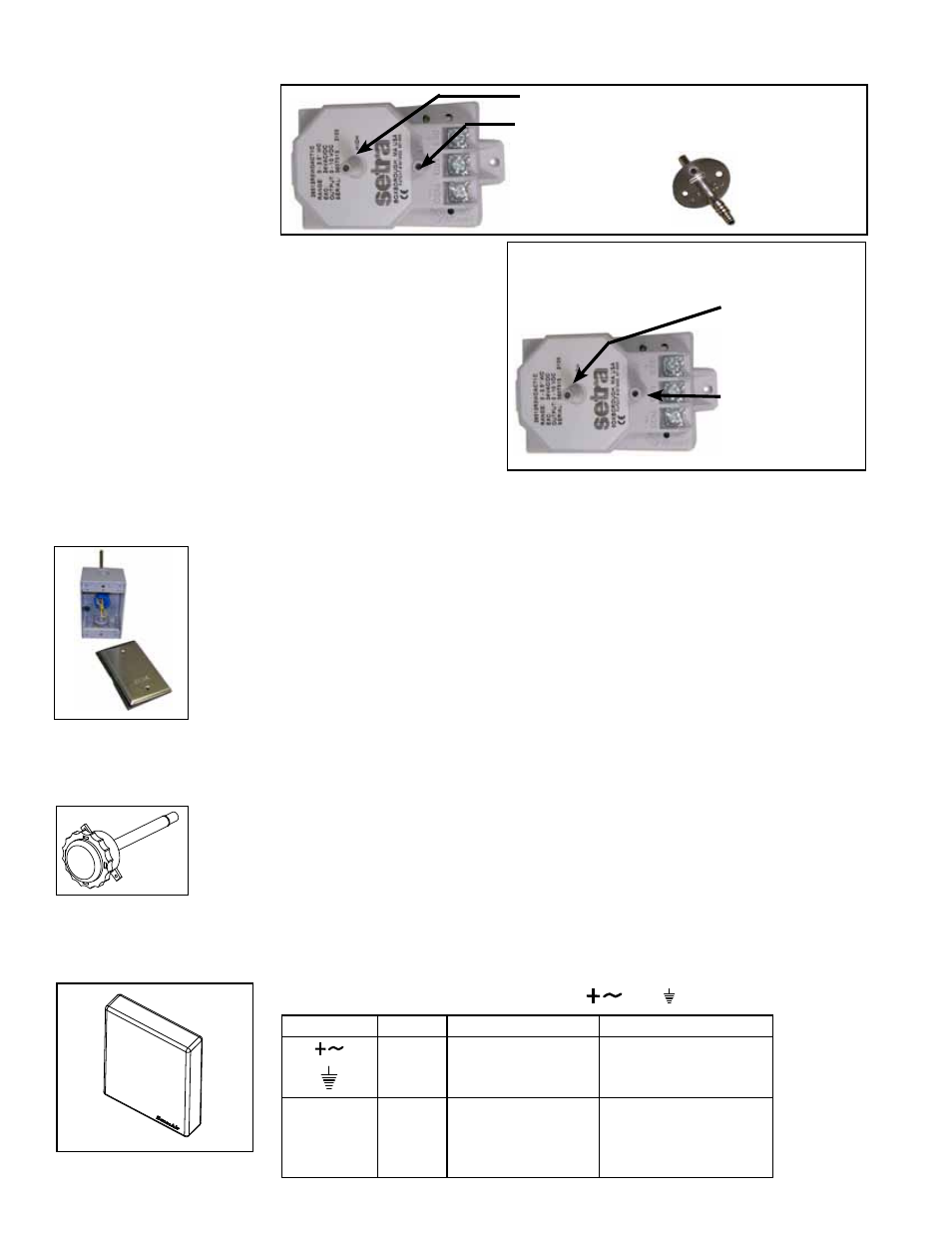

FIGURE 28A -

Tubing Ports on the

Transducer in Option

BE11 and Ductwork

Sensor Port

High Pressure Port - Attach tubing.

Low Pressure Port -

Leave open.

or attach

tubing.

High Pressure

Data Sensor

Port - Attach to

ductwork. Slide

tubing on barb.

Option BE12, Building Static Pressure Sensor

The differential pressure transducer (

P/N 234819) used in

Option BE12 is mounted in the low voltage compartment. The

transducer has a high and a low tubing port. Depending on the

application, attach tubing to both ports or leave one open to

atmospheric pressure. Connect 1/4" field-supplied tubing to the

port(s) and run it to the pressure reference point(s). Cut the end

of the tubing at a 45° angle to minimize the affect of air move-

ment and attach it to a wall or in a ceiling. The transducer has

a range of -0.5 to .5" w.c. and was calibrated at the factory; it

should not need field adjustment. Refer to the manufacturer's

instructions in the owner's envelope for additional information.

High Pressure

Port - Connect to

the high pressure

reference point.

Low Pressure

Port - Connect to

the low pressure

reference point.

FIGURE 28B - Tubing Ports on Option

BE12, Building Static Pressure Sensor

8.1 Cooling/ Dehumidification/Heating Control (cont'd)

8.0 Controls

(cont'd)

Option BE13, Return Air Temperature Sensor

The return air temperature sensor (

P/N 222753) is shipped loose for field installation

in the return air ductwork. The position of the sensor is important. In a horizontal return

air ductwork, locate the sensor assembly in the top, middle of the duct with the sensor

probe extending vertically down into the center of the airstream. In vertical return air

ductwork, locate the sensor assembly in the middle of the side of the duct that corre-

sponds with the middle of the discharge outlet.

Mark the location and drill a 7/16" hole. Insert the probe in the hole. With the probe

centered in the hole, attach with two #8 sheetmetal screws. Be sure the hole is sealed.

Refer to Paragraph 8.1.1 and follow the same guidelines for the sensor wire. Wires

will attach to the sensor and to the controller expansion board. Refer to the unit wiring

diagram.

Option BE14, Return Air Humidity Sensor

The return air humidity sensor (

P/N 234907) is shipped loose for field installation in the

return air ductwork. The sensor must be located away from areas of excessive mois-

ture, corrosive fumes, vibration, or extremely high temperature.

To install, mark the selected location and drill a 3/4" hole. Insert the stainless steel

probe into the hole until the foam is in direct contact with the duct. Attach the RH trans-

mitter using two #8 x 3/4" self-tapping screws.

Follow the requirements in Paragraph 8.1.1 to run the sensor wire. To connect the wire

to the sensor, remove the cover and install conduit connectors.

Wires will connect to the controller expansion board. Refer to the unit wiring diagram.

FIGURE 28C - Return

Air Temperature

Sensor, P/N 222753

Option BE15, Building CO

2

Sensor

The sensor (

P/N 234820) used in Option BE15 must be field mounted in the building

and electrically connected to the I/Q controller expansion board (Option BHB6). Follow

the manufacturer's instructions to mount the sensor. Connect the wires as instructed

below. Power supply must be connected to

and

FIGURE 28D -

Return Air Humidity

Sensor, P/N 234907

Sensor Terminal

Function

Electrical Data

Remarks / Standard Settings

Power (+)

Power

ground (-)

24 VAC/DC+ (±10%), 2W

24 VAC/DC -

System voltage reference

OUT 1

OUT 2

Analogue

output 1 (+)

Analogue

output 2 (+)

0-10 VDC

2.0-10.0 VDC or 4.0-20.0 mA

0.9 - 1.6 VDC or 1.5-2.5mA

0 VDC or 0 mA

0-2000 ppm CO2

0-2000 ppm CO2

Status = ERROR

Status = NOT READY

FIGURE 28E - CO2

Sensor, P/N 234820

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual