2 gas heat - rdcb, rddb, rdcc, rddc, Sensor and for the control system, 2 gas heat - models rdcb, rddb, rdcc, rddc – Reznor RECC Unit Installation Manual User Manual

Page 55: 1 gas heat module - mechanical

Form I-MAPSIII&IV, P/N 222917R9, Page 55

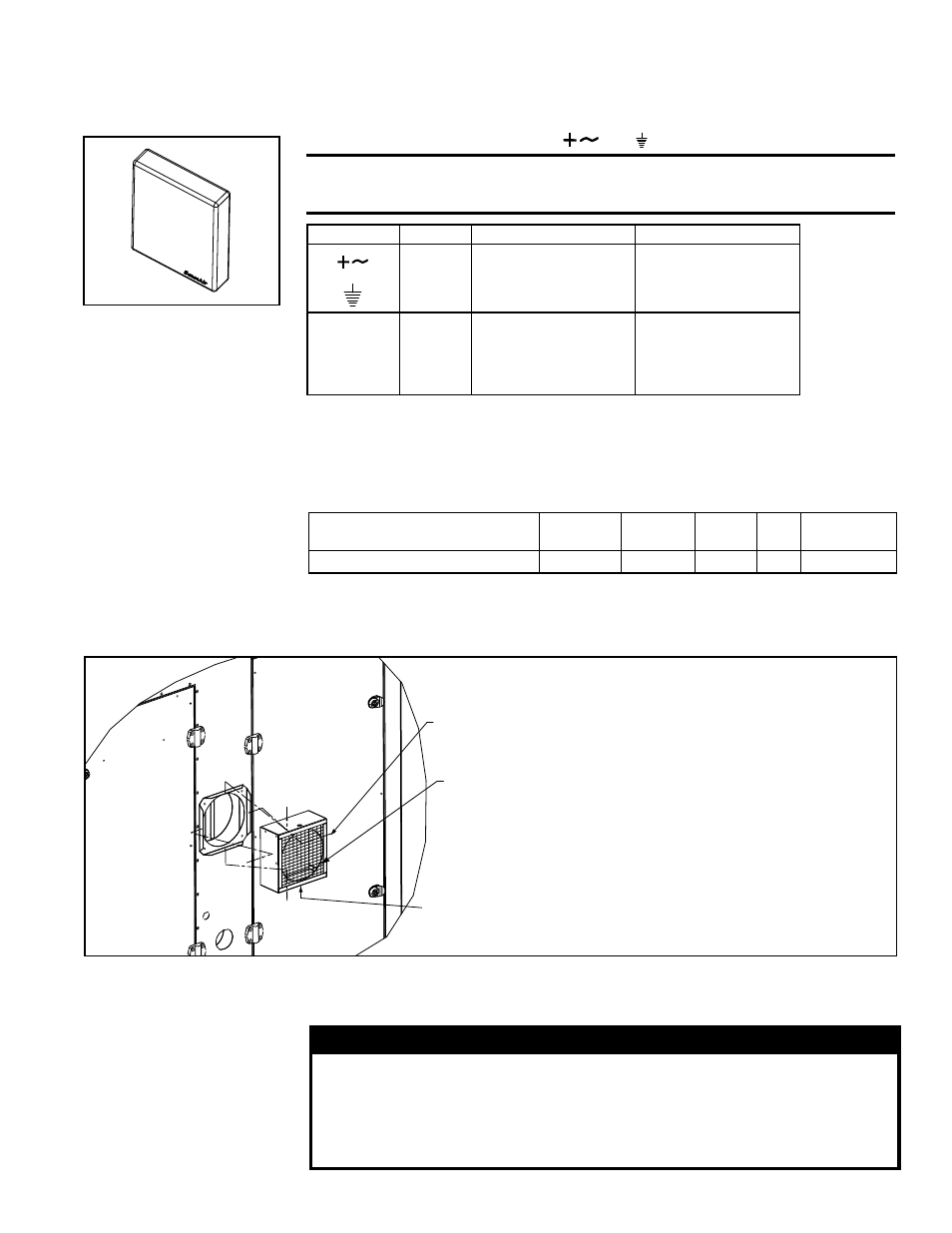

Option GF6, Building CO

2

Sensor

The sensor (

P/N 234820) used in Option GF6 must be field mounted in the building

and electrically connected to the I/Q controller expansion board (Option BHB6). Follow

the manufacturer's instructions to mount the sensor. Connect the wires as instructed.

Power supply must be connected to

and

CAUTION: The same ground reference has to be used for the

CO

2

sensor and for the control system.

FIGURE 35B - CO2

Sensor, P/N 234820

Sensor Terminal

Function

Electrical Data

Remarks /Standard Settings

Power (+)

Power

ground (-)

24 VAC/DC+ (±10%), 2W

24 VAC/DC -

System voltage reference

OUT 1

OUT 2

Analogue

output 1 (+)

Analogue

output 2 (+)

0-10 VDC

2.0-10.0 VDC or 4.0-20.0 mA

0.9 - 1.6 VDC or 1.5-2.5mA

0 VDC or 0 mA

0-2000 ppm CO2

0-2000 ppm CO2

Status = ERROR

Status = NOT READY

9.2 Gas Heat -

Models RDCB,

RDDB, RDCC,

RDDC

A system with a gas heat section is equipped with a Reznor

®

T

CORE

2

®

combustion sys-

tem from 100 to 1,600 MBH input. The 80% thermal efficient furnace is power vented

and has either a staged gas control or depending on size either a 8:1 or 16:1 turndown

modulating gas capacity control.

Temperature Guidelines

for Gas Heat Section

Minimum Circulating Discharge

Air Temperature (°F)

80

75

70

65

60

Minimum Design Ambient (°F)

-30 to - 21 -20 to - 11 -10 to -1 0 to 9 10 and above

9.2.1 Gas Heat

Module - Mechanical

9.2.1.1 Screened Vent Cover - MAPS

®

III "D" Cabinet

The vent cover is shipped with the unit for field installation. Each package includes the

assembled vent cover,

P/N 222614, and four sheetmetal screws, P/N 11813.

FIGURE 36 - Install a Vent Cover on

Each Gas Furnace - D Cabinet Sizes

Vent Cover Assembly,

P/N 222614

(1 for Sizes 500,

600, 700, 800;

2 for Sizes 1000,

1200, 1400, 1600)

Sheetmetal Screws,

P/N 11813 (4 for each

vent box assembly)

Drain hole MUST be

on the bottom.

Instructions

1. Position the cover over the vent

being sure that the drain hole in

the box is toward the bottom.

2. Attach the vent cover with the four

screws as illustrated.

3. On heat sections with two

furnaces (Cabinet D Sizes 1000,

1200, 1400, and 1600), install a

vent cover on each furnace.

9.2.1.2 Gas Piping and

Pressures

All piping must be in accordance with requirements outlined in the National Fuel Gas

Code ANSI/Z223.1a (latest edition) or CSA-B149.1 and B149.2. Gas supply piping

installation should conform with good practice and with local codes.

WARNING: PRESSURE TESTING SUPPLY PIPING

Test pressures ABOVE 1/2 psi (3.5kPa): Disconnect the heater

and the manual valve from the gas supply line which is to be

tested. Cap or plug the supply line. Test pressure EQUAL TO or

BELOW 1/2 psi (3.5kPa): Before testing, close the manual valve

at the heater.

- REDB Unit Installation Manual RECB Unit Installation Manual RDDC Unit Installation Manual RDCC Unit Installation Manual RDDB Unit Installation Manual RDCB Unit Installation Manual RDC Unit Installation Manual RCC Unit Installation Manual RDB Unit Installation Manual RCB Unit Installation Manual REDC Unit Installation Manual MAPSIV Unit Installation Manual MAPSIII Unit Installation Manual