Pressure depth measurement, Flow velocity measurement – ADS Environmental Services FlowShark Pulse QR 775004 A1 User Manual

Page 33

System Overview and Operation

4-3

Adding the sensor offset to the measured depth value (h

1

) determines the depth total

(h). The sensor offset represents the distance from the bottom of the pipe to the

sensor crystal position. The measured depth value represents the distance from the

crystal to the flow surface.

Pressure Depth Measurement

The combi sensor may have an integrated hydrostatic depth measurement device.

This piezoresistive pressure sensor operates according to the relative pressure

principle, where the pressure of the standing water column above the sensor is

directly proportional to the depth level. This device can measure depth levels even

when the combi sensor is installed away from the bottom center of the pipe.

During installation, this sensor must be calibrated based on a manual depth

measurement and the position of the sensor in the pipe.

Flow Velocity Measurement

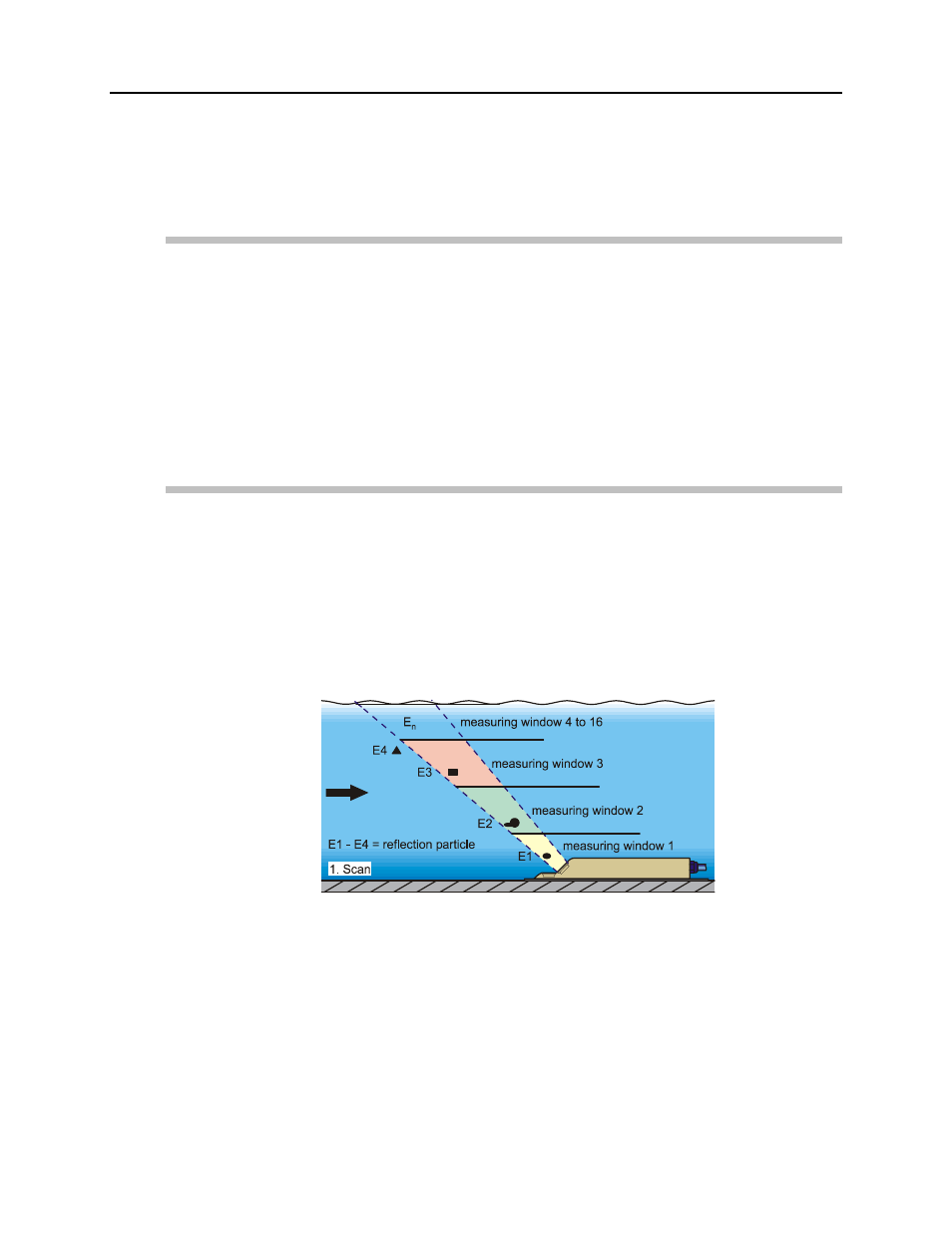

The combi sensor has a piezo crystal for measuring flow velocity. This crystal sends

an ultrasonic pulse at a defined angle into the oncoming flow. All air and/or dirt

particles in the path of the pulse reflect a small amount of the ultrasonic signal. The

size and shape of a particle determines the result of the reflected signal. Together, the

returned signals produce a reflection pattern (Figure 4-2) received by the piezo

crystal. This pattern is converted into electric signals that are loaded into a digital

signal processor (DSP) housed in the sensor.

Fig. 4-2: Conditions at first signal detection

After a certain period, the sensor sends a second ultrasonic pulse into the flow. The

DSP also saves the new reflected signal.

Flow velocities differ at varying depth levels, creating a velocity profile. Therefore,

the distances (or movement) between reflective particles’ initial and subsequent

positions also vary at different depth levels, resulting in a distorted reflection pattern

(Figure 4-3). Several other factors also influence particle reflection and velocity

profile measurement. Rotating particles may exhibit multiple shapes for reflection;