Rockwell Automation 1746-HSRV SLC Servo Control Module User Manual User Manual

Page 94

Publication 1746-6.1.2 - July 2000

Setting Up Your SLC Servo Module 7-15

AC line conditions. If you don’t meet these conditions, you experience

excessive error faults during high speed operation. You must select

the proper motor, drive, and gearing to satisfy the above requirement

for the application. AC power to the motor drive can go as low as 85%

of the nominal input voltage. To allow for axis operation at low line

conditions, use a power line factor between 0.85 and 1.0. Select a

power line factor based on motor and drive vendor specification.

The maximum low line operating speed (from the motor data sheet

plus gearing) can be calculated by performing the following:

Operating at maximum speed that you want, select a DAC output

saturation speed greater than the operation speed that you want. A

reasonable percentage of maximum is approximately 105%. The DAC

output saturation speed is the maximum speed for the axis, and we

calculate it as follows:

In the example below, select a 3000 rpm motor for use with the

previous example in this section. Compute the maximum operating

speed using the following equation:

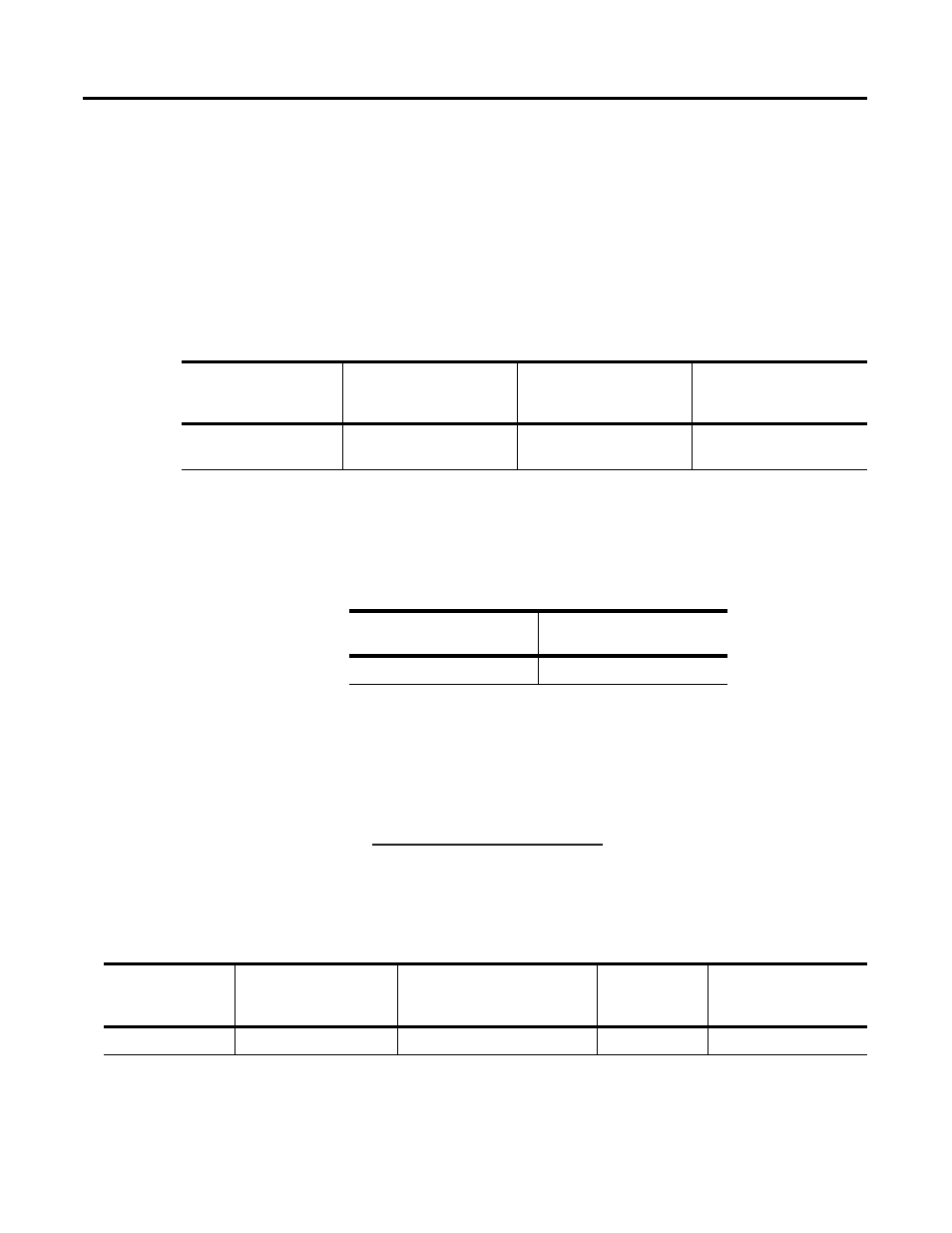

Maximum operating

speed for the axis is

equal to:

Multiplied by:

Multiplied by:

Multiplied by:

Power line factor

Maximum motor rpm

Output revolutions/

input revolutions

1/pitch

Maximum operating speed

is equal to:

Multiplied by:

1.05

Maximum speed that you want

(Power Factor)

*

(RPM

*

(Encoder lines

*

4)

Counts per Position Units

=

Maximum Operating Speed

Power factor:

Multiplied by:

revolutions per minute

(RPM)

Multiplied by:

Encoder lines * 4

Divided by:

Counts per

position units

Equals maximum

operating speed:

0.85

3000

4000

60000

170 (ipm)