Rockwell Automation 1746-HSRV SLC Servo Control Module User Manual User Manual

Page 71

Publication 1746-6.1.2 - July 2000

5-28 Wiring the SLC Servo Module

because it directly affects how the 1398 is wired to the SLC Servo

Module.

Wiring the SLC Servo Module when Homing to a Marker

Both the ULTRA 100 drive (using any divisible resolution) and the

ULTRA 200 drive (using any divisible resolution) require a breakout

board (P/N 9101-1392) to interface between the integral encoder

(inside the Y, F, or H-series motor) and the SLC Servo Module

termination panel.

The breakout board allows the SLC Servo Module to read the encoder

signals directly from the encoder, instead of from the gate array circuit

inside the ULTRA 100/200. If the encoder signals are read from the

ULTRA 100/200 (using the gate arrays), the marker signal shifts with

respect to the A and B channel on each successive power cycle to the

ULTRA 100/200.

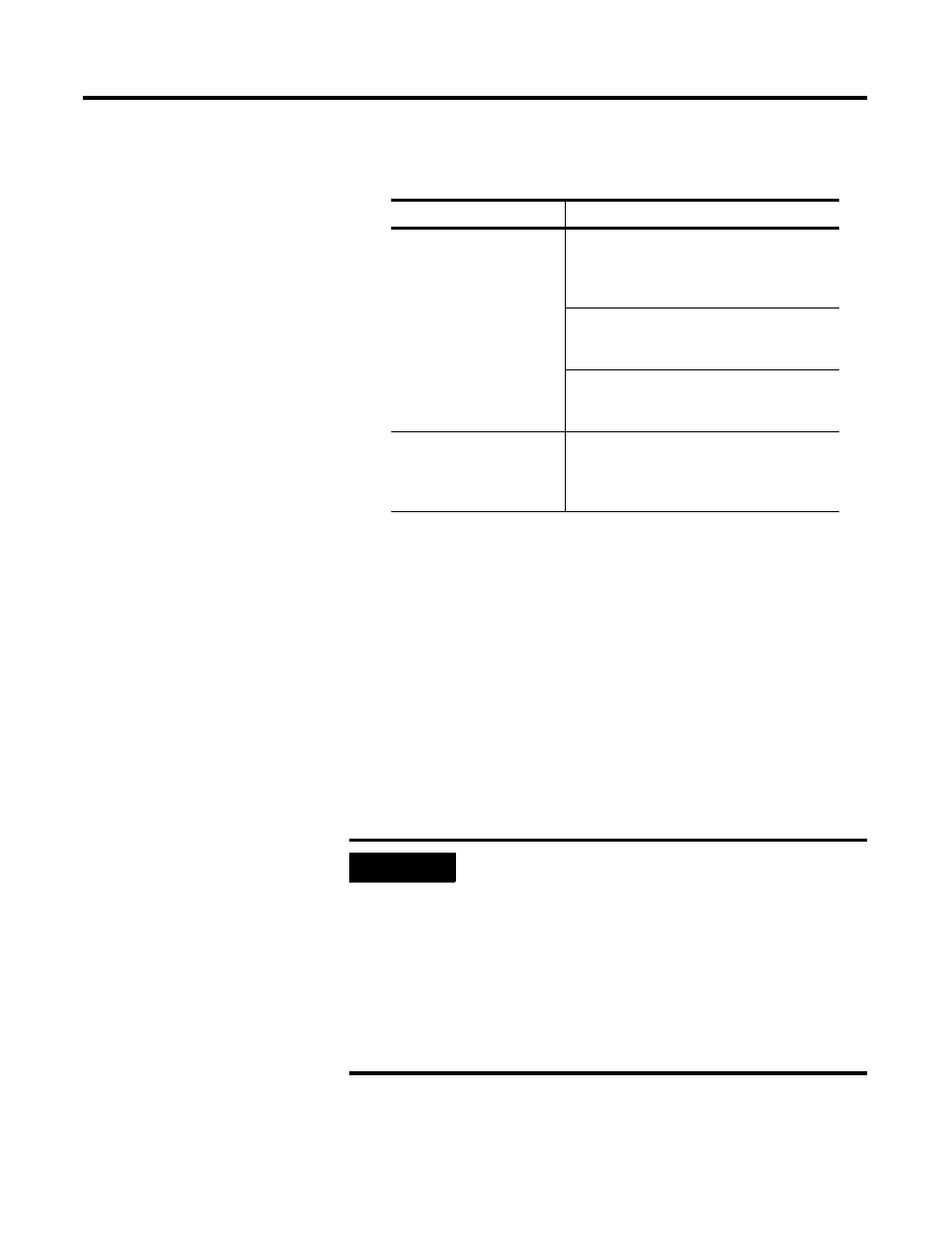

If Homing to a Marker is:

Go to:

Necessary

Figure 5.24,

Wiring Diagram for ULTRA 100

When Not Homing to a Marker and for ULTRA

200 (Manufactured After July 31, 1998) When

Homing to a Marker

Figure 5.25,

Wiring Diagram for F, H, and S

series ULTRA 100/200 (Manufactured Before

July 31, 1998) When Homing to a Marker

Figure 5.26,

Wiring Diagram for Y series

ULTRA 100/200 (Manufactured Before July 31,

1998) When Homing to a Marker

Not Necessary

Figure 5.24,

Wiring Diagram for ULTRA 100

When Not Homing to a Marker and for ULTRA

200 (Manufactured After July 31, 1998) When

Homing to a Marker

IMPORTANT

Since the ULTRA 100/200 drive can be configured to

use custom motors and custom encoders, the

guidelines stated above may not be true for other

manufacturers’ motor/encoder combinations.

ULTRA 200 drives manufactured after July 31, 1998

do not need the J2 breakout. Look for a mm/yy

date code stamped or printed on the Allen-Bradley

label, located on the side of each drive unit. For

example: Mfg. 1098 indicates the drive was

manufactured in October 1998.