Classifying your conductors, Placing your slc servo module – Rockwell Automation 1746-HSRV SLC Servo Control Module User Manual User Manual

Page 34

Publication 1746-6.1.2 - July 2000

Planning Hardware Installation 3-3

Classifying Your

Conductors

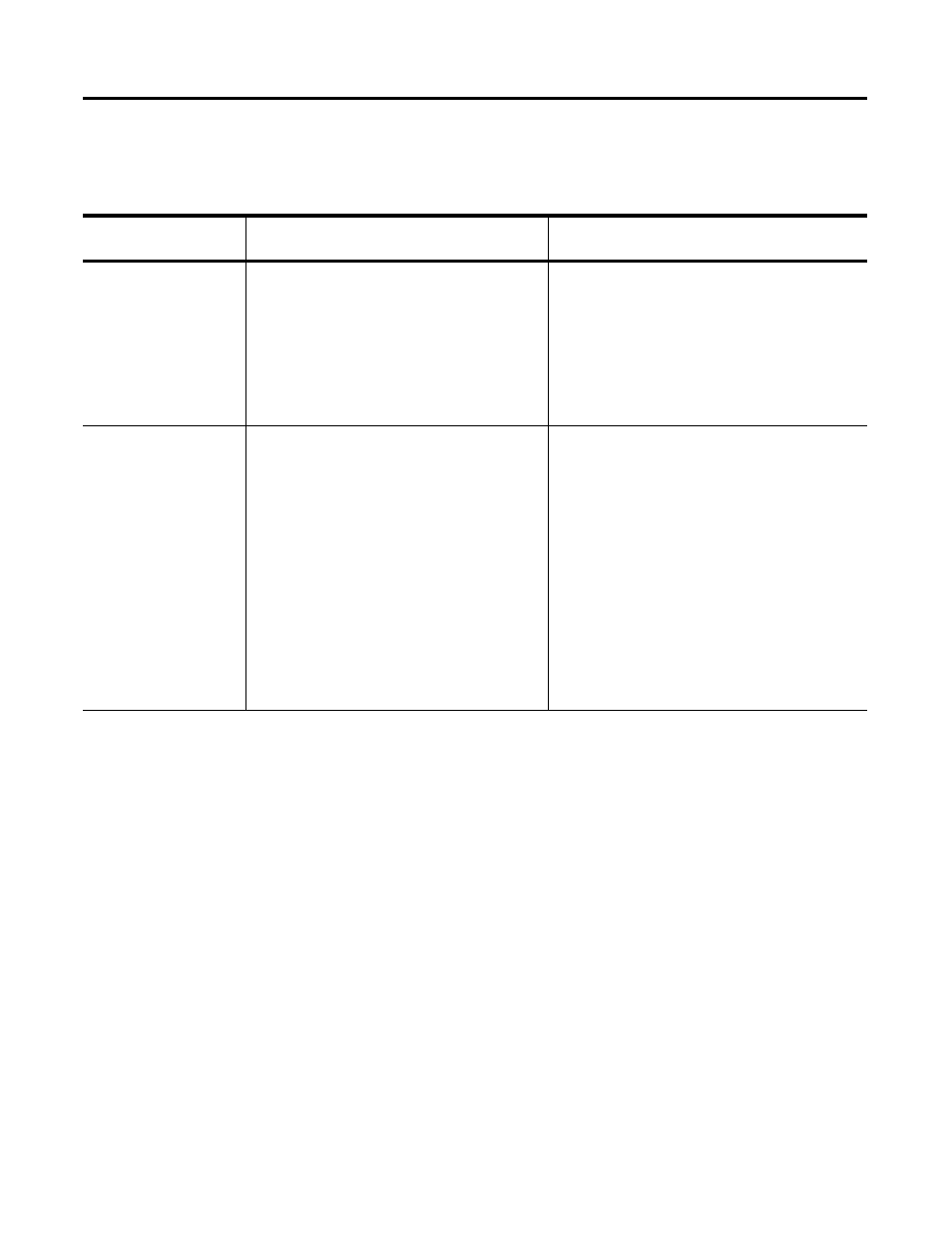

Use the table below for cable routing guidelines and determining wire

and cable functions.

Placing Your SLC Servo

Module

When you plan your SLC Servo Module placement:

•

Divide modules, as much as possible, into the following types:

•

AC

•

High-level DC

•

Low-level digital DC (TTL, encoder, pulse output)

•

Analog I/O

•

Intelligent I/O modules (for example, the SLC Servo Module)

•

Place the SLC Servo Module as close to the SLC processor as

possible.

•

Keep your SLC Servo Module as far away as possible from DC

and AC I/O modules. Distance protects the intelligent

(CPU-based) modules from the heat and electrical noise of the

DC and AC I/O modules.

For these wires

and cables:

To:

Follow these guidelines for routing inside or

outside an enclosure:

AC power lines

•

Connect high-power AC I/O lines to AC I/O

modules that are rated for high power and

high noise immunity.

•

Connect high-power DC I/O lines to DC I/O

modules that are rated for high power or

have input circuits with long time constant

filters for high noise rejection. They typically

connect to devices such as hard-contact

switches, relays, and solenoids.

•

Route these high-power AC lines with machine

power conductors of up to 600V AC (feeding up

to 100 hp devices) if this does not violate local

codes.

•

Article 300-3 of the National Electrical Code

requires that all conductors (AC and/or DC) in

the same raceway are insulated for the highest

voltage applied to any one of the conductors in

the raceway.

SLC Servo Module cable

(1746-HCA) and

termination panel wiring

•

Connect serial communication cables to

programming terminals or data terminals,

and connect them from the scanner to

remote I/O adapter modules or PLC

processors.

•

Connect low-power AC/DC I/O lines to I/O

modules that are rated for low power such

as low-power contact-output modules.

•

Connect low-power DC I/O lines to DC I/O

modules that are rated for low power and

have input circuits with short time constant

filters to detect short pulses. They typically

connect to devices such as proximity

switches, photo-electric sensors, TTL

devices, encoders, motion control devices,

and analog devices.

•

Properly shield conductors, where applicable,

and route them in separate raceways. If

conductors must cross power feed lines, they

should do so at right angles.

•

Route these lines at least 1 foot from 110V AC

power lines, 2 feet from 240V AC power lines,

and 3 feet from 480V AC power lines.

•

Route these lines at least 3 feet from any

electric motors, transformers, rectifiers,

generators, arc welders, induction furnaces, or

sources of microwave radiation.

•

If the conductor is in a metal raceway or

conduit, that raceway or conduit must be

grounded along its entire length.