Major fault messages – Rockwell Automation 1746-HSRV SLC Servo Control Module User Manual User Manual

Page 171

Publication 1746-6.1.2 - July 2000

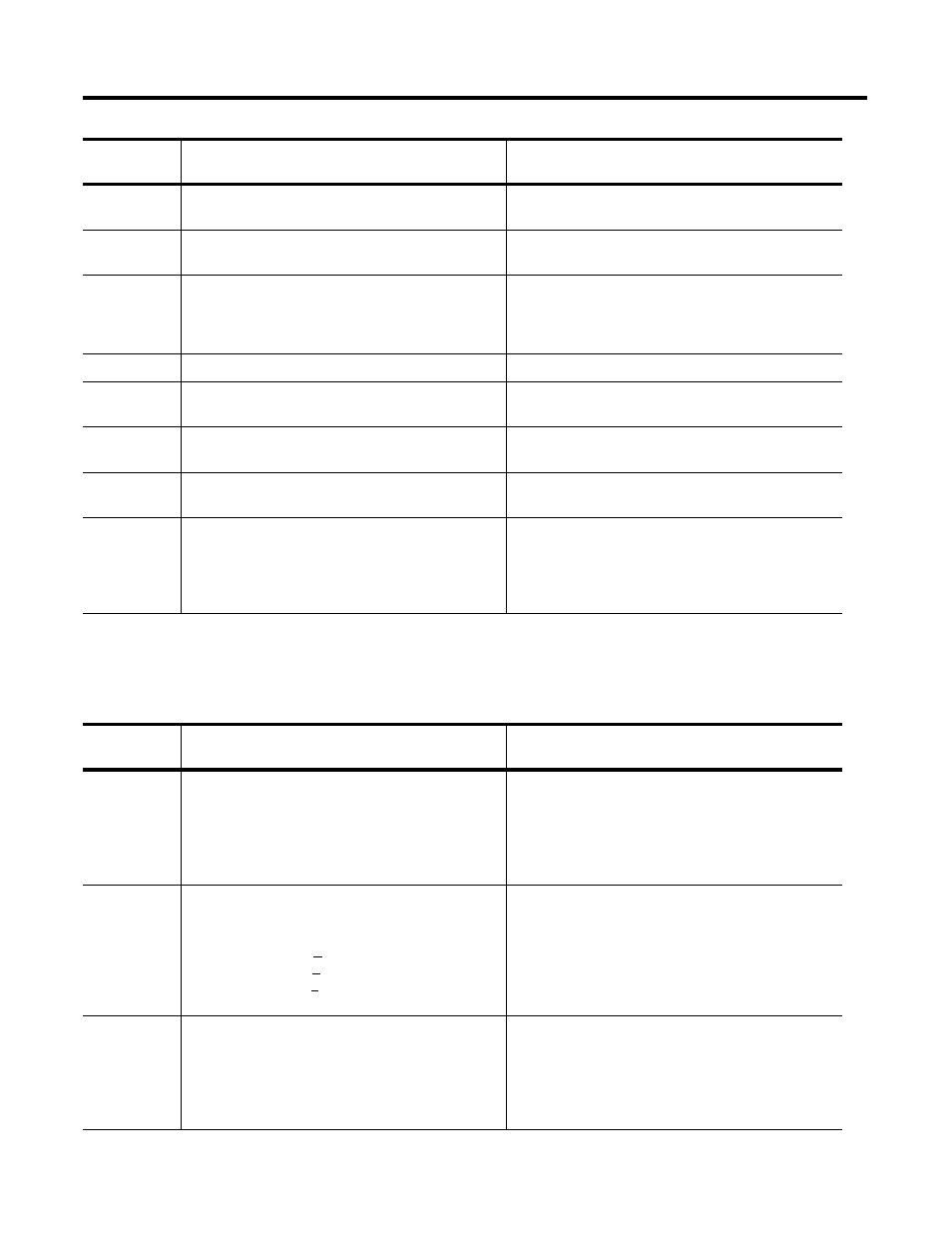

10-12 Troubleshooting

Major Fault Messages

1063

The excess follower error is out of range.

If the excess FE is too big or too small, change the

parameter.

1064

The in position band is out of range.

If the in position band is too big or too small, change the

parameter.

1065

The loop type specified is out of range.

Valid loop types for the two bit field are:

00 - Open Loop

10 - FE Loop

01 - ZFE Loop (VFF)

1066

The home type specified is out of range.

Change the parameter.

1067

The positive overtravel limit specified is out of range.

The specified value caused an overflow error when

converting the parameter to internal resolution units.

1068

The negative overtravel limit specified is out of range.

The specified value caused an overflow error when

converting the parameter to internal resolution units.

1069

The counts per position unit specified is out of range.

The specified value caused an overflow error when

converting the parameter to internal resolution units.

1070

The fits per CIT is out of range.

The valid values are:

3 = 4.8 msec

4 = 6.4 msec

5 = 8.0 msec

6 = 9.6 msec

Minor Fault

Message No.

Potential Cause

Possible Resolution

Major Fault

Message No.

Potential Cause

Possible Resolution

2048

Quadrature fault: simultaneous transitions on the A and

B channels of the encoder detected. This error causes

an Estop state.

Because this fault is typically due to electrical noise

coupling onto the feedback lines:

1. Check to make sure the feedback cable is isolated

from electrical fields; and all relays, contactors,

and solenoids are adequately suppressed.

2. Rehome the system.

2049

The SLC Servo Module detected a feedback fault that

causes an Estop state. This occurs if the SLC Servo

Module detects one of the following in the same

electrical state:

•

channel

A and A

•

channel

B and B

•

channel

Z and Z

Because this fault is typically due to electrical noise

coupling onto the feedback lines:

1. Check to make sure the feedback cable is isolated

from electrical fields; and all relays, contactors,

and solenoids are adequately suppressed.

2. Rehome the system.

2050

The value of the axis following error exceeded the limit

established in the configuration file. This can be caused

by an obstruction to axis motion, servo wiring error, or

loss of feedback channel. This error causes Estop.

Reversal error is greater than maximum position

following error.

1. Reset from Estop.

2. If the problem persists, check axis mechanics,

wiring, and feedback devices.

3. Make reversal error smaller than maximum

position

following error.