Before programming the slc servo module, Data type conversions – Rockwell Automation 1746-HSRV SLC Servo Control Module User Manual User Manual

Page 91

Publication 1746-6.1.2 - July 2000

7-12 Setting Up Your SLC Servo Module

resume until the SLC processor has transferred the information to the

M0 file of the SLC Servo Module.

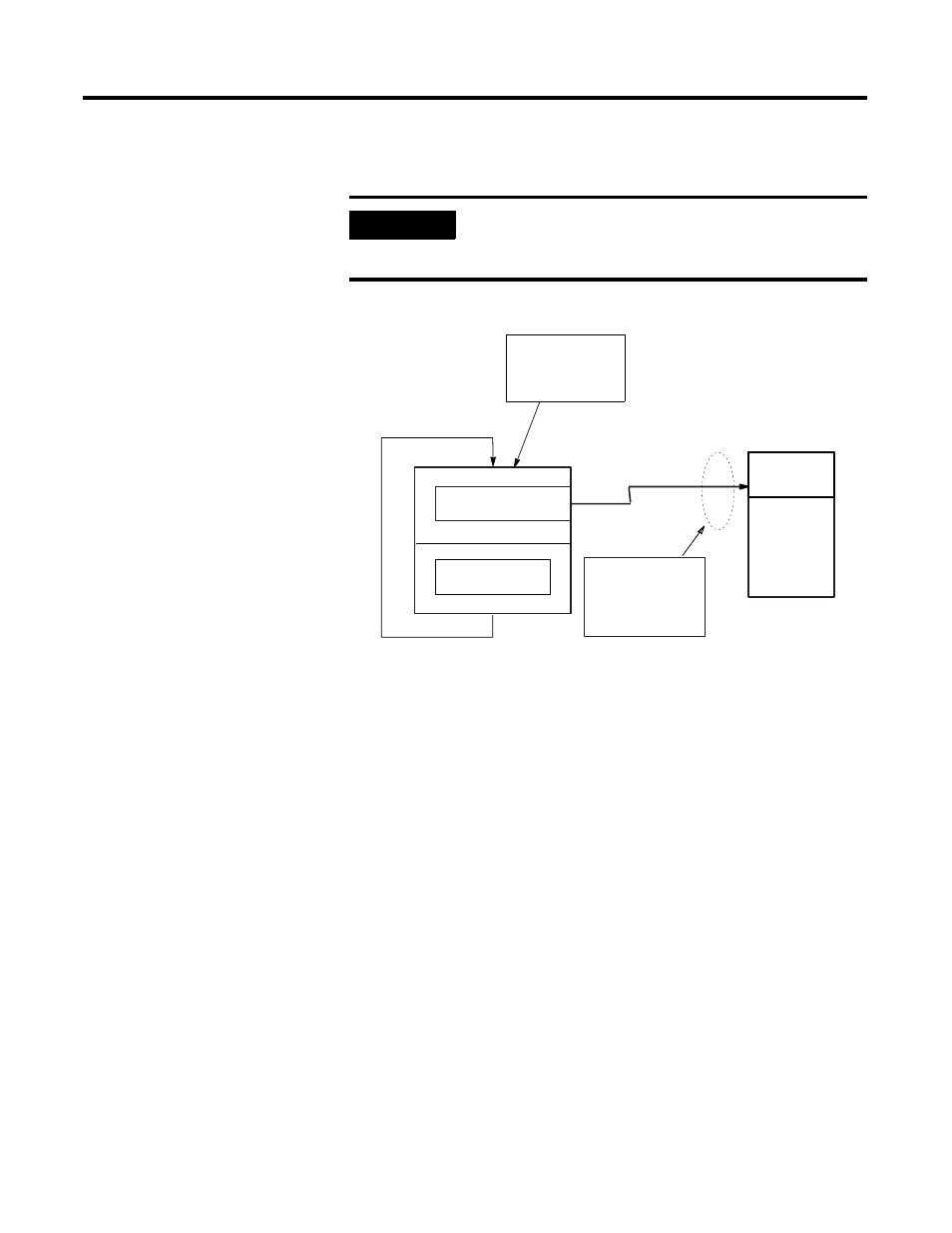

Figure 7.1 Relationship Between Ladder Scan Time and Repeated Execution

Data Type Conversions

The SLC Servo Module uses floating-point values to configure and

operate. However, I/O files do not allow floating-point numbers. To

use floating-point values in I/O files, you must execute a COP (or

copy) instruction.

When you use a COP command you have to determine the number of

words in the destination file. I/O file words are 16 bits in length.

Floating-point values are 32 bits, or two words, in length. If you copy

a floating-point value to an I/O file, it occupies two words. If you

copy two I/O words to a floating-point value, they occupy one

floating-point value. Floating-point values are 32 bits.

Before Programming the

SLC Servo Module

Before programming your SLC Servo Module:

1. Power-up the SLC Servo Module to initialize the default

configuration.

IMPORTANT

Repeatedly executing the copy file instruction when

you download the configuration increases the ladder

scan time as shown in Figure 7.1.

Copy File to M0

I/O SCAN

Configuration

Data

Transferred

Immediately

M0 File

SLC

Servo

Module

SLC LADDER

EXECUTION