Logix system reaction time, Configuring the sil 2 task period and watchdog, Sil task/program instructions – Rockwell Automation 1715-OF8I Redundant I/O System User Manual User Manual

Page 220

220

Rockwell Automation Publication 1715-UM001C-EN-P - March 2014

Chapter 6

1715 Redundant I/O System in SIL 2 Safety Applications

Logix System Reaction Time

The following sections provide information on calculating the Logix System

Reaction Time for a simple input-logic-output chain and for a more complex

application using produced/consumed safety tags in the logic chain.

Simple Input-logic-output Chain

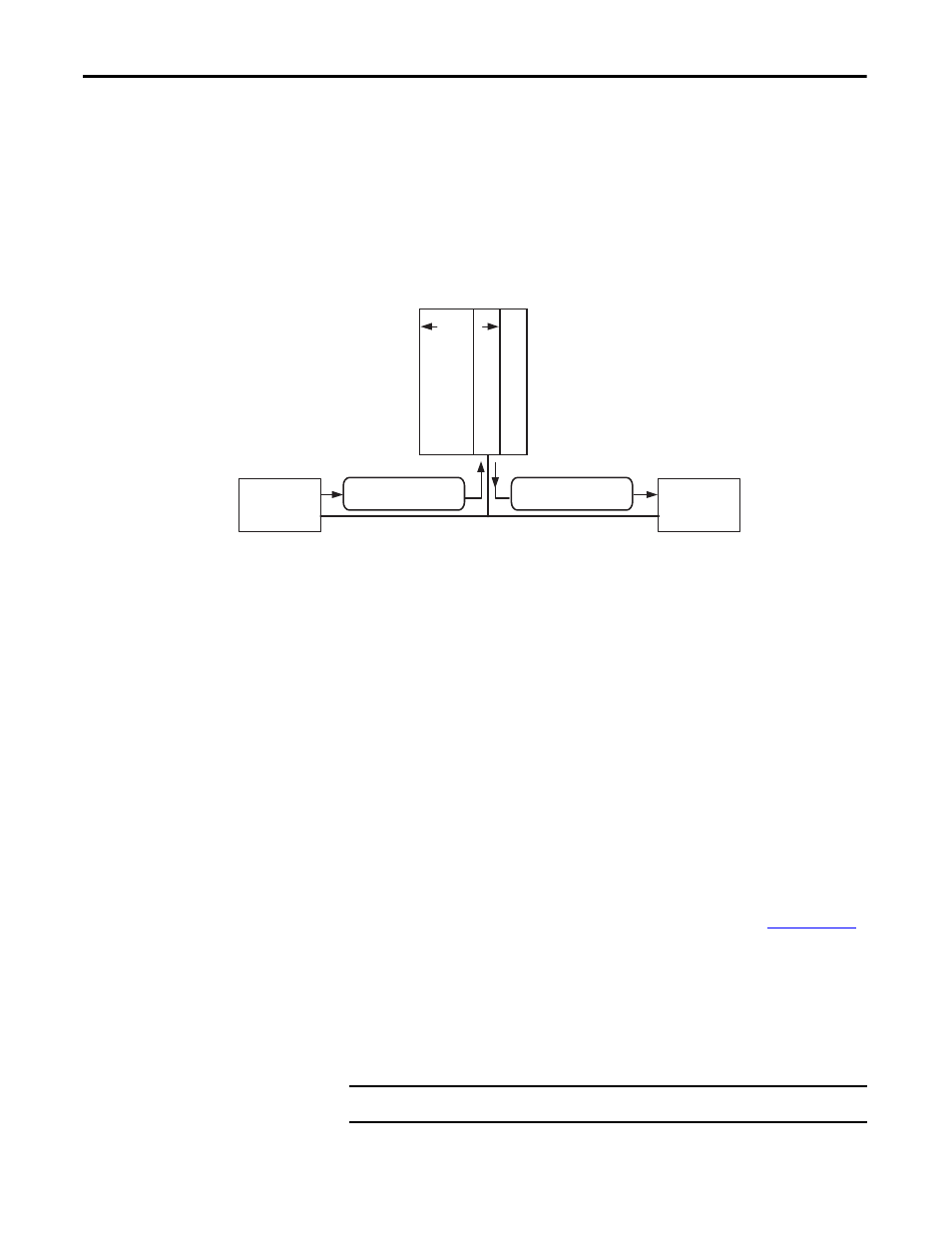

Figure 64 - Logix System Worst-case Reaction Time for Simple Input to Logic to Output

The Logix System Reaction Time for any simple input to logic to output chain

consists of these five components.

1. Safety input module reaction time plus input delay time

2. Safety Input Connection Reaction Time Limit

(Read from the Module Properties dialog box in RSLogix 5000 software.)

3. Safety Task Period plus Safety Task Watchdog time

4. Safety Output Connection Reaction Time Limit

(Read from the Module Properties dialog box in RSLogix 5000 software.)

5. Safety output module reaction time

Configuring the SIL 2 Task

Period and Watchdog

This SIL 2 task is a periodic task with priority (1). Refer to the Using

ControlLogix SIL 2 Applications Reference Manual, publication

1756-RM001

.

SIL Task/Program Instructions

The user application must contain a single SIL task composed of programs and

routines. The SIL 2 task must be the controller’s top priority task and the user-

defined watchdog must be set to accommodate the SIL 2 task.

1. Safety Input

Module Delay

5. Safety Output

Module Delay

2. Safety Input Connection

Reaction Time Limit

4. Safety Output Connection

Reaction Time Limit

CIP Safety Network

Co

m

m

un

ica

tio

n M

od

ul

e

Gu

ar

dL

og

ix

Co

nt

ro

ller

3. Safety Task Period +

Safety Task Watchdog

IMPORTANT

Motion-related functions are not allowed and must not be used.