Rockwell Automation 198x Modular DeviceNet Starter Auxiliary I/O User Manual

Page 41

3-21

Publication 198-UM001B-EN-P September 2001

Since this information is dynamically established during the power-up sequence, these

parameters can not be accessed through the standard EDS. There are two basic steps to set

these parameters. First, map your particular configuration of modules, then use the

&ODVV

,QVWDQFH (GLWRU under the 'HYLFH menu.

1. To begin configuring the parameters, you must determine the instance number of the

I/O points for your particular configuration. The instance number for any system

begins counting from the left to the right. An example of determining instance

numbers is found below.

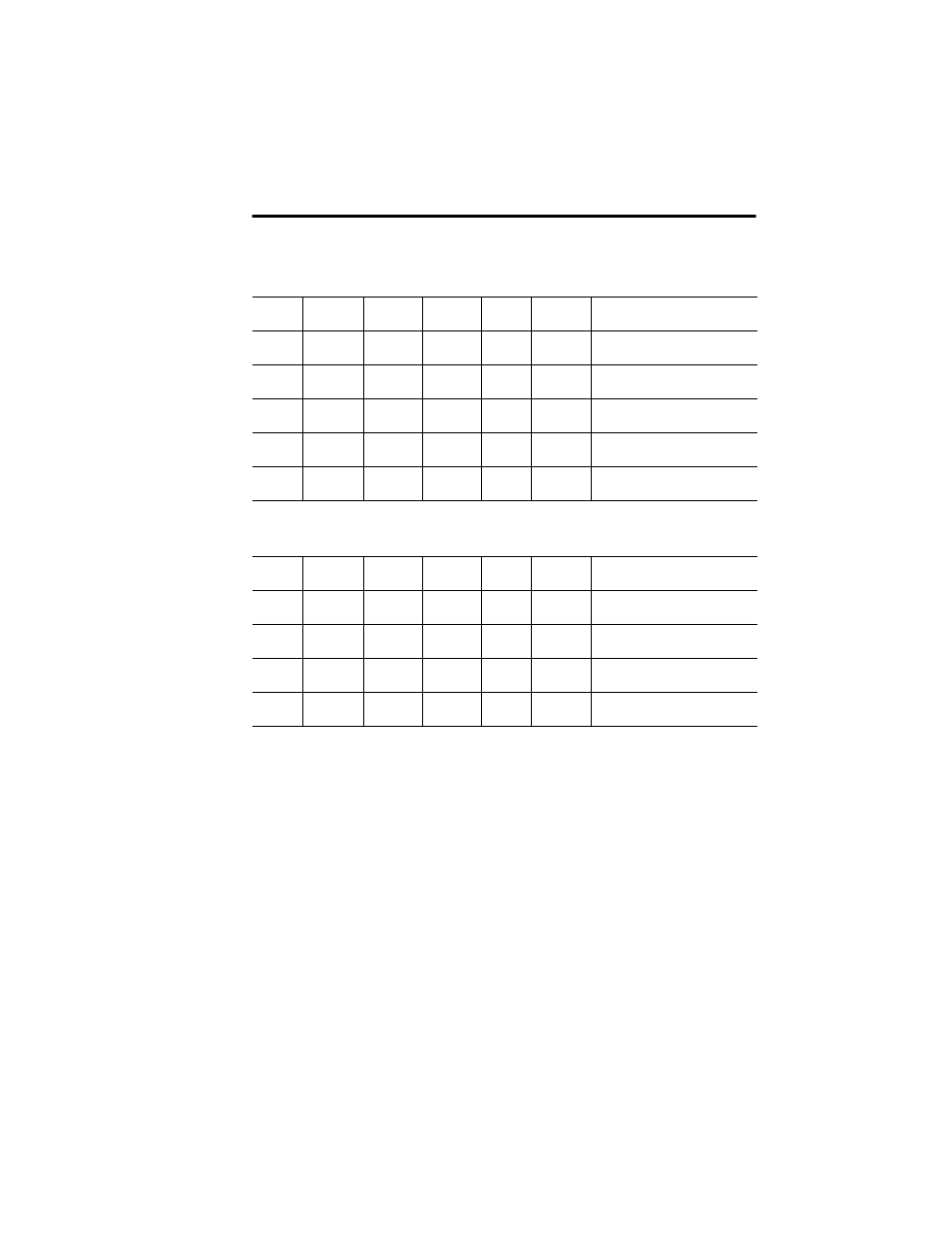

Table 3.B Discrete Output Point Object

Class ID Instance

ID

Attribute

ID

Access

Rule

Name

Data Type Value

9

1 or 2

3

Get/Set

Value

BOOL

0 = Off

1 = On

9

1 or 2

5

Get/Set

Fault

Action

BOOL

0 = Go to Fault value

1 = Hold Lasts State

9

1 or 2

6

Get/Set

Fault

Value

BOOL

0 = Off

1 = On

9

1 or 2

7

Get/Set

Idle

Action

BOOL

0 = Got to Idle State

1 = Hold Last State

9

1 or 2

8

Get/Set

Idle

Value

BOOL

0 = Off

1 = On

Table 3.C Presence Sensing Object

Class ID Instance

ID

Attribute

ID

Access

Rule

Name

Data Type Value

14

1 or 2

1

Get

Output

BOOL

0 = No signal present

1 = Signal present

14

1 or 2

8

Get/Set

Operate

Mode

BOOL

0 = Output attribute as specified

1 = Output Attribute inverted

14

1 or 2

122

Get

Open

BOOL

0 = No open condition

1 = Open condition detected

14

1 or 2

123

Get

Short

BOOL

0 = No short condition

1 = Short condition detected