Danger – MacDon M100 SP Operators Manual User Manual

Page 92

HEADER OPERATION – A SERIES

169304

90

Rev. C

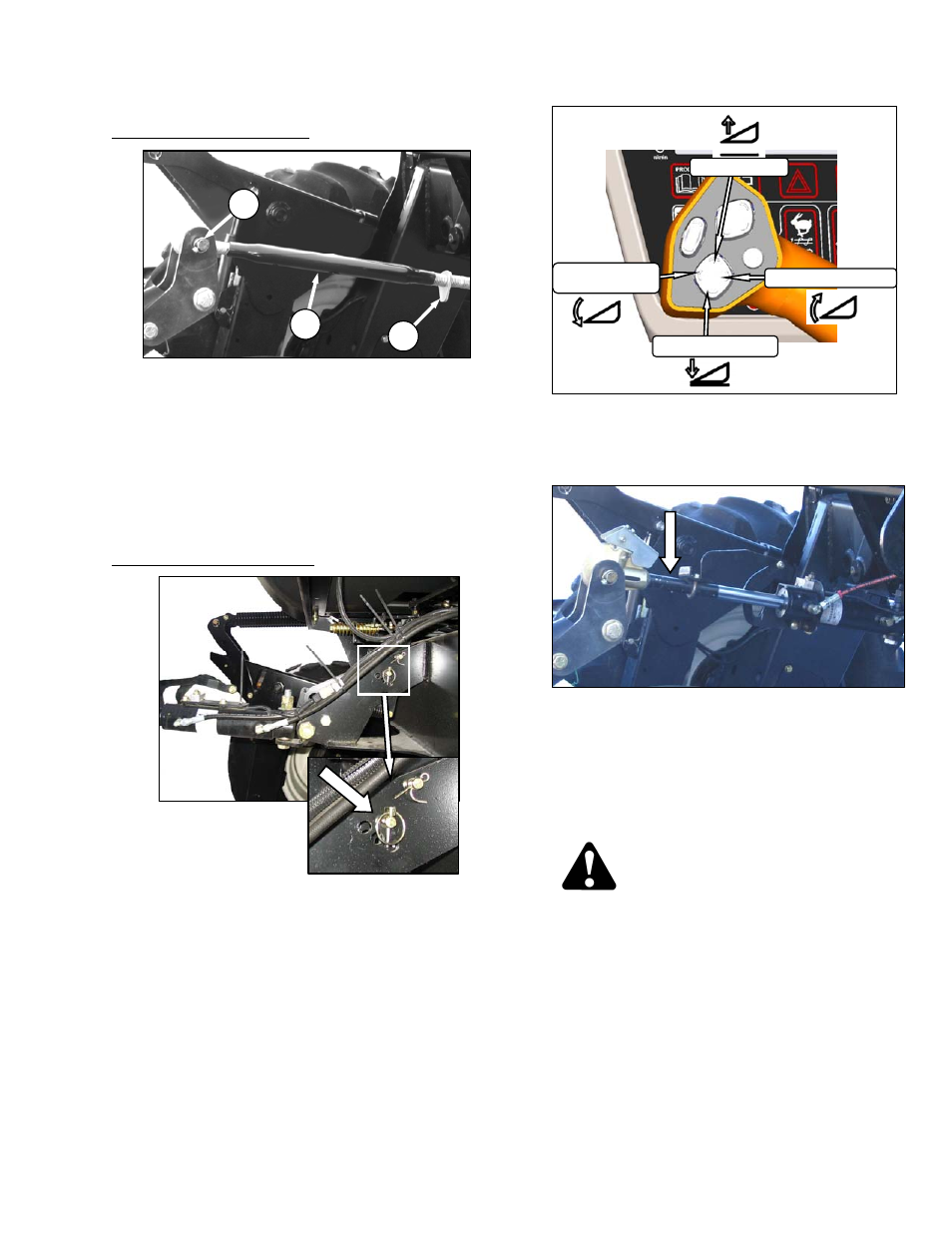

d. Connect center link as follows:

MECHANICAL LINK – M150

1. Loosen nut (F) and rotate barrel (G) to

adjust length so that other end lines up with

header bracket.

2. Install pin (H) and secure with cotter pins.

3. Adjust link to required length for proper

header angle by rotating barrel (G). Tighten

nut (F) against barrel. A slight tap with a

hammer is sufficient.

4. Proceed to step e.

HYDRAULIC LINK - OPTION

1. Re-locate the pin at the frame linkage as

required to position the hook over the

header pin.

2. Activate HEADER TILT cylinder switches on

GSL to extend or retract center link cylinder

so that the hook lines up with the header

attachment pin.

3. Push down on rod end of link cylinder until

hook engages pin on header and is locked.

4. Check that center link is locked onto header

by pulling upward on rod end of cylinder.

e. Raise the header fully with THE HEADER UP

switch on the GSL. Stop engine and remove

key.

DANGER

To avoid bodily injury from fall of raised

header, always engage header lift cylinder

stops when working on or around raised

header.

f. Engage lift cylinder stops on both lift cylinders.

Refer to Section 6.4.1 Header Lift Cylinder

Stops.

(continued next page)

G

F

H

HEADER UP

HEADER TILT UP

HEADER DOWN

HEADER

TILT DOWN