Danger – MacDon M100 SP Operators Manual User Manual

Page 167

MAINTENANCE/SERVICE

169304

165

Rev. C

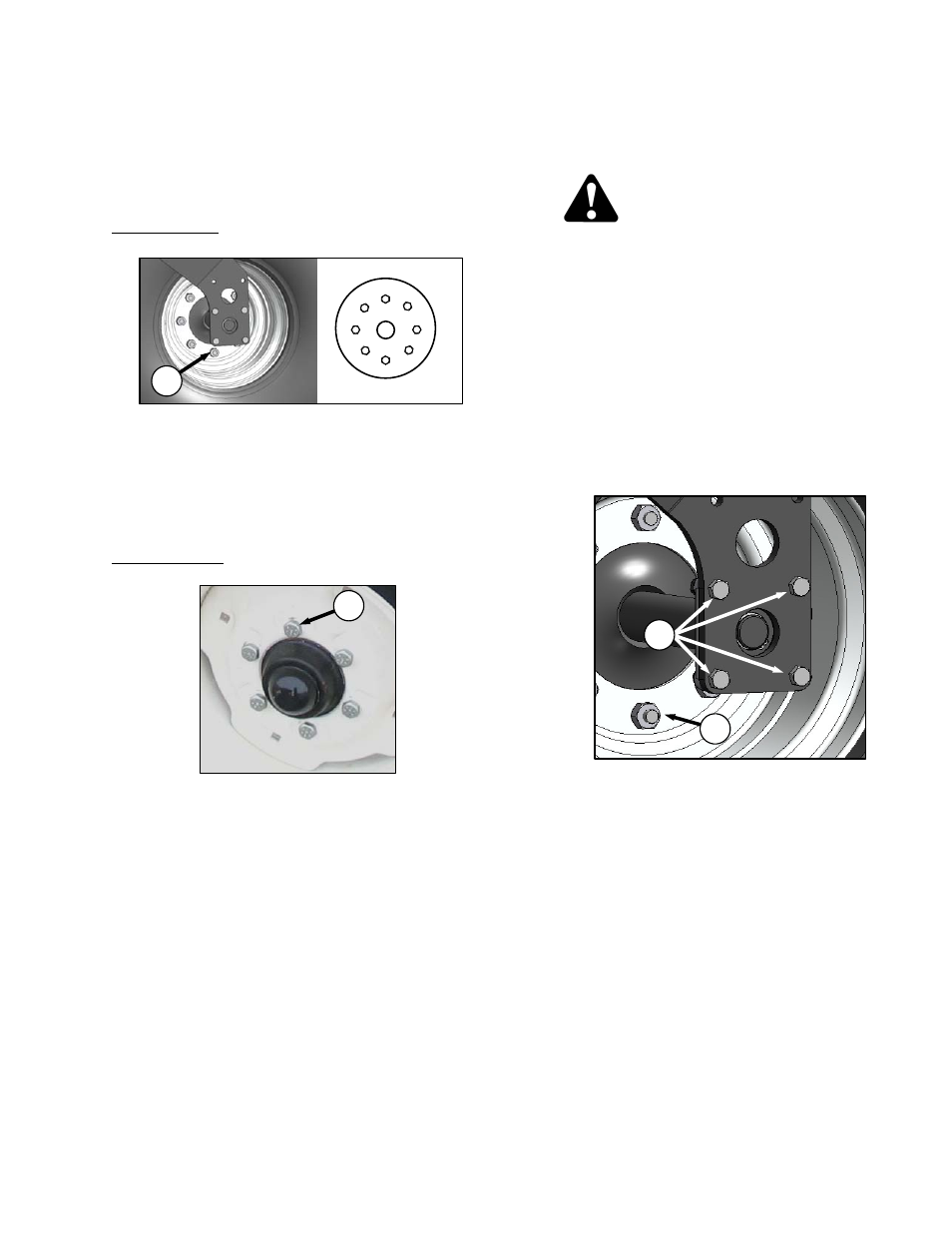

57.10.2.3 Wheel Nut Torque

At first use, or when a wheel is removed, check

caster wheel bolt torque as follows after 5 hours

and then at 200 hour intervals:

Forked Casters

a. Tighten nuts (A) to 120 ft·lbf (163 N·m) using the

tightening sequence as shown.

NOTE

To avoid damage to wheel disks, do not

over-tighten wheel nuts.

b. Repeat sequence three times.

Formed Casters

a. Tighten bolts (B) to 120 ft·lbf (163 N·m) using

the tightening sequence as shown.

NOTE

To avoid damage to wheel disks, do not

over-tighten wheel bolts.

b. Repeat sequence three times.

57.10.2.4 Forked Caster Wheel

Removal/Installation

DANGER

To avoid severe personal injury or death

caused by machine runaway, shut off engine

and remove key before performing any of the

following checks and/or adjustments.

a. Remove the caster wheel as follows:

1. Park windrower on level ground and block

all wheels.

2. Place GSL in N-DETENT, shutdown engine

and remove key.

3. Raise end of walking beam using a 2000 lb

(908 kg) capacity jack or other suitable lifting

device until the wheel is slightly off the

ground.

4. Remove the eight bolts (C) attaching axle to

forked caster and remove wheel assembly

from caster.

5. Undo the eight wheel nuts (D) and remove

wheel from axle.

b. Install the caster wheel as follows:

1. Position wheel on axle and install wheel nuts

(D).

2. Torque nuts (D) as specified in previous

section.

3. Position wheel assembly in forked caster

and install with bolts (C). Torque bolts to

75-79 ft·lbf (97-107 N·m).

4. Lower windrower and remove jack.

D

C

1

5

3

2

4

6

B

A

1

5

3

7

8

2

4

6