Warning, Danger – MacDon M100 SP Operators Manual User Manual

Page 154

MAINTENANCE/SERVICE

169304

152

Rev. C

57.9 HYDRAULIC SYSTEM

The M100 Windrower hydraulic system provides

oil for the windrower drive system, and header

lift and drive systems.

Hydraulic schematics are placed at the back of

this manual.

WARNING

Avoid high pressure fluids. Escaping fluid

can penetrate the skin causing serious

injury. Relieve pressure before

disconnecting hydraulic lines. Tighten all

connections

before applying

pressure. Keep

hands and body

away from pin-

holes and nozzles

which eject fluids

under high

pressure. Use a

piece of

cardboard or

paper to search

for leaks. If ANY

fluid is injected

into the skin, it

must be surgically removed within a few

hours by a doctor familiar with this type of

injury or gangrene may result.

IMPORTANT

Dirt, dust, water and foreign material are

the major causes of trouble developing in

the hydraulic system. If the hydraulic

system should be disconnected for

service, protect the ends of hoses, tubing

and ports of components from

contamination with clean, lint-free towels

or clean plastic bags. Before installing

any replacement hose, flush the inside of

it with unused diesel fuel or unused

commercial petroleum cleaning solvent for

ten seconds minimum. Do not use water,

water soluble cleaners or compressed air.

IMPORTANT

The components in this system are built to

very close tolerances and have been

adjusted at the factory. Do not attempt to

service these components except to

maintain proper oil level, change oil and

filters and to adjust relief pressures as

described in this manual. See your

Windrower Dealer for all other service.

57.9.1 Oil Level

Check hydraulic oil level when oil is cold for

most accurate reading:

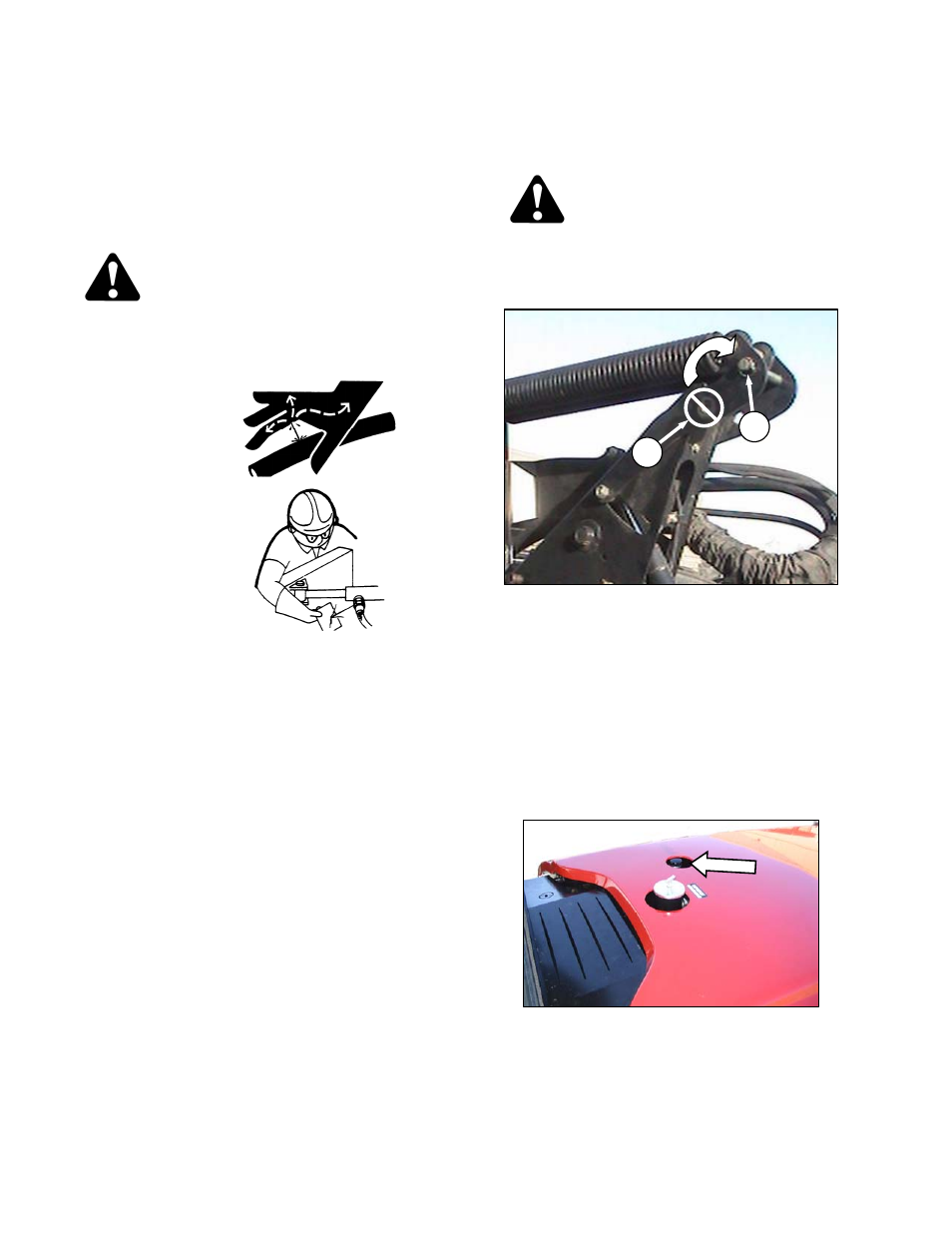

DANGER

Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could engage

an idling machine.

IMPORTANT

To prevent damage to the lift system when

lowering header lift linkages without a

header or weight box attached to

windrower, ensure that float engagement

pin is installed in storage location (A), and

not installed at hole location (B).

a. Park windrower on level ground and lower

header and reel so that lift cylinders are fully

retracted.

b. Stop engine and remove key.

c. Stand on platform to access the filler pipe.

d. Turn filler cap counterclockwise to loosen bung,

and remove dipstick.

(continued next page)

B

A