MacDon M100 SP Operators Manual User Manual

Page 116

MAINTENANCE/SERVICE

169304

114

Rev. C

2. Move pintle arm a small amount forward and

hold so that LH wheel rotates forward for 2

or 3 seconds.

3. Move pintle arm a small amount rearward

and hold so that LH wheel rotates backward

for 2 or 3 seconds.

4. Position pintle arm so that the LH wheel

remains stationary and the pump is the

quietest to obtain the exact neutral position.

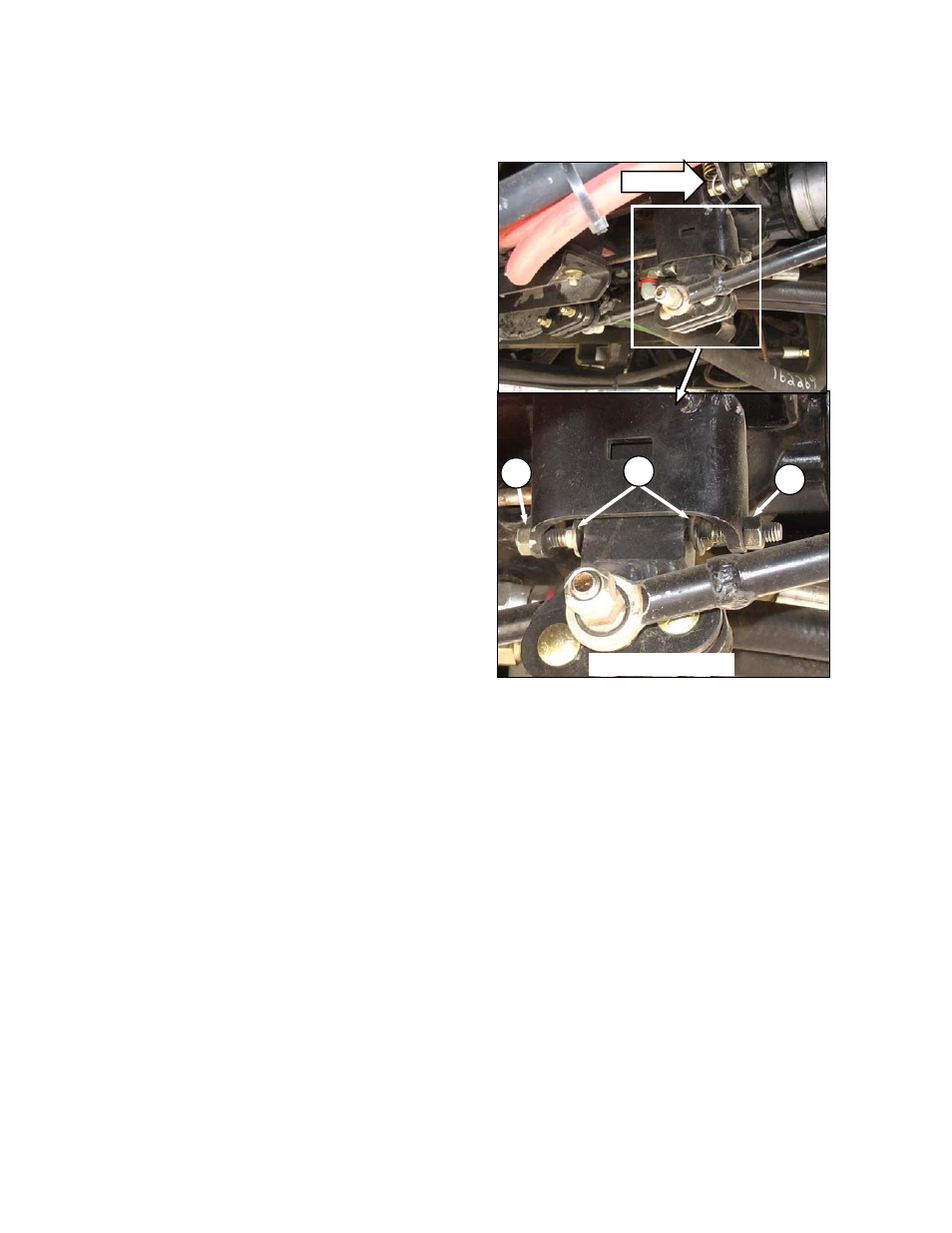

5. Turn the forward adjusting bolt (E) by hand

until it contacts the pintle arm.

6. Move the pintle arm firmly against the

adjusting bolt to check the setting – it’s

acceptable for the LH wheel to just begin to

creep forward. Hand tighten the jam-nut (D)

at the forward adjusting bolt.

7. Return pintle arm to the neutral position.

8. Turn the rear adjusting bolt (E) by hand until

it contacts the pintle arm.

9. Move the pintle arm firmly against the rear

adjusting bolt to check the setting – it’s

acceptable for the LH wheel to just begin to

creep backward. Hand tighten the jam-nut

(D) at the rear adjusting bolt.

10. Verify the adjusting bolt setting by again

moving the pintle arm forward, then

rearward to check that the LH wheel just

begins to creep in both cases.

11. Fully tighten jam-nuts on both adjusting

bolts. Ensure that the bolts do not rotate as

the jam-nuts are tightened.

12. Check that the rear interlock engages and

disengages freely onto the pintle arm in the

neutral position.

h. Adjust FRONT pintle interlock (actuates RH

wheel) using same procedure for the REAR

pintle:

i. Apply a small amount of grease to the head of

the adjusting bolts.

j. Shut-off

engine.

k. Check GSL position in N-DETENT and adjust as

necessary. See 7.7.3.3.

l.

Reconnect connector V3 at brake solenoid 3.

m. Close maintenance platform.

n. Lower machine to ground.

D

FWD

FRONT PINTLE

D

E