Installation, 8 wall support for the remote version – KROHNE OPTIFLEX 2200 C_F EN User Manual

Page 42

3

INSTALLATION

42

OPTIFLEX 2200 C/F

www.krohne.com

07/2013 - 4000668002 - HB OPTIFLEX 2200 R02 en

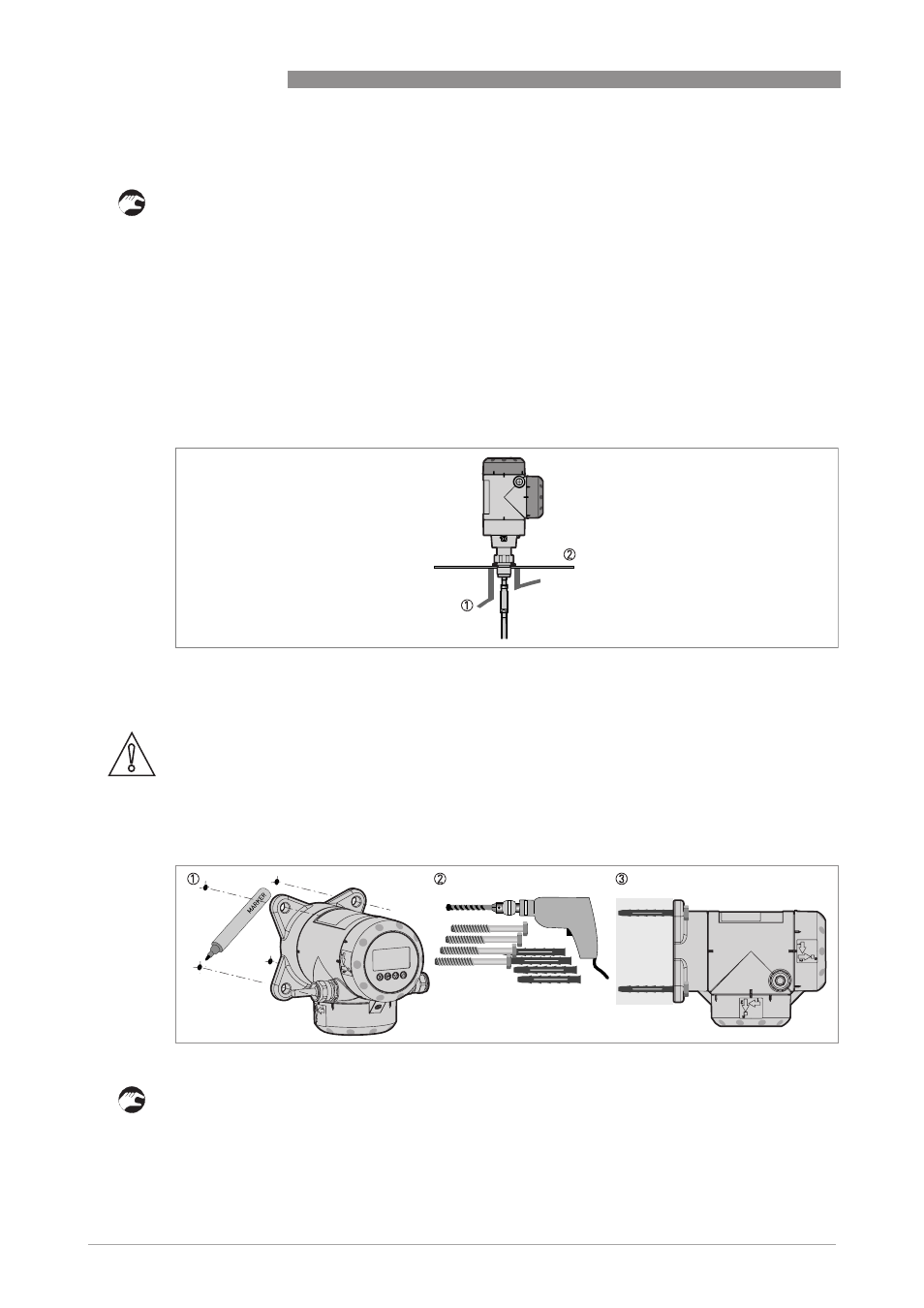

3.8.7 Recommendations for pits and tanks made of non-conductive materials

If you have a device with a single rod or a single cable probe and a thread connection,

obey these instructions:

• Put a metal sheet between the device and the process connection.

i

It must have a diameter greater than 200 mm / 8¨.

• Make sure that the metal sheet is in contact with the thread stop on the device.

We recommend that you use DN≥200 / ≥8¨ for flange connections.

If you have a device with a double rod, double cable or coaxial probe, you can ignore these

instructions.

3.8.8 Wall support for the remote version

1 Use marks on the wall to help you put the wall support in the correct position. For more data,

refer to

Dimensions and weights

on page 128.

2 Use equipement and tools that agree with health and safety regulations and good engineering

practice.

Figure 3-37: Installation in a non-metallic tank or pit with a thread connection

1 Non-metallic (plastic...) tank or pit

2 Metal sheet, Ø ≥200 mm / 8¨

CAUTION!

When the device is installed, make sure that the tank roof has no deformation.

Figure 3-38: Wall support for the remote version (attached to the remote converter)