Operation – KROHNE OPTIFLEX 1300C EN User Manual

Page 90

6

OPERATION

90

OPTIFLEX 1300 C

www.krohne.com

03/2014 - 4000172306 - HB OPTIFLEX 1300 R07 en

6.4.7 How to make the device follow the correct level or interface signal

If the distance measurement stays on one value when the level of the product changes, the

device has probably selected a parasitic signal as the level signal. You can set the device to the

correct value with the Distance Input

Distance Input

Distance Input

Distance Input function.

The Distance Input

Distance Input

Distance Input

Distance Input function, used with the signal screen, makes the device look for the level or

the interface (if the device is configured for interface applications) at the correct point along the

probe. A distance value must be given by the supervisor. The distance is measured from the

flange facing or thread stop to the surface of the product.

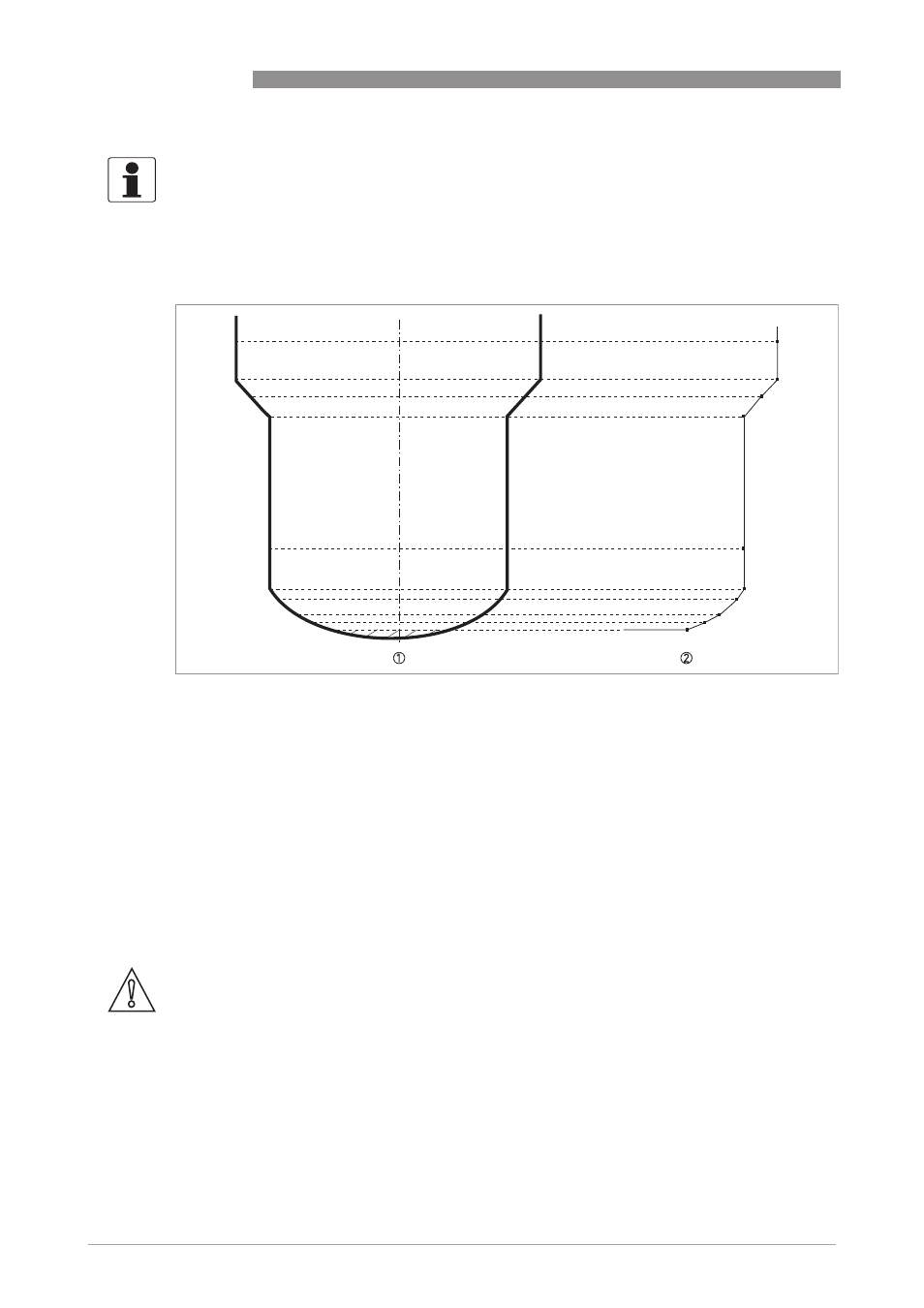

The signal screen is divided into 4 areas, as shown in the illustration that follows:

INFORMATION!

When you create a table, get more conversion data for parts of the tank where there are:

•

Surfaces with curves.

•

Sudden changes in the cross section.

This will make volume measurement more accurate.

Figure 6-6: A plot of points for a volume or mass table

1 Tank with reference points

2 Tank model with plotted points

CAUTION!

Do not give a distance value that is in the dead zones of the device. For more data, refer to

Measurement limits on page 141

.