Siemens S5-135U/155U User Manual

Page 40

3-14

System Manual

C79000-G8576-C199-06

3.3.2

Equipotential Bonding

Between separate sections of an installation, potential differences can

develop if

S

programmable controllers and I/O devices are connected via a

non-floating link, or

S

cable shields are connected at both ends and are grounded at different

parts of the system.

Different AC supplies, for example, can cause potential differences. These

differences must be reduced by installing equipotential bonding conductors to

ensure functioning of the electronic components.

The following points must be observed for equipotential bonding:

S

The lower the impedance of the equipotential bonding conductor, the

greater is the effectiveness of equipotential bonding.

S

Where shielded signal lines are laid between the relevant sections of the

system and connected at both ends to the ground/protective conductor, the

impedance of the additional equipotential bonding conductor must not

exceed 10 % of the shield impedance.

S

The cross-section of the equipotential bonding conductor must be rated

for the maximum circulating current. The following cross-sections of

copper have proved to be satisfactory in practice:

–16 mm

@ of copper for equipotential bonding conductors

of up to 200 m in length

–25 mm

@ of copper for equipotential bonding conductors

of more than 200 m in length.

S

Use copper or zinc-plated steel for equipotential bonding conductors.

They must be given a large-area connection to the ground/protective

conductor and protect it from corrosion.

S

The equipotential bonding conductor should be laid so that the smallest

possible areas are enclosed between the equipotential bonding conductor

and signal lines.

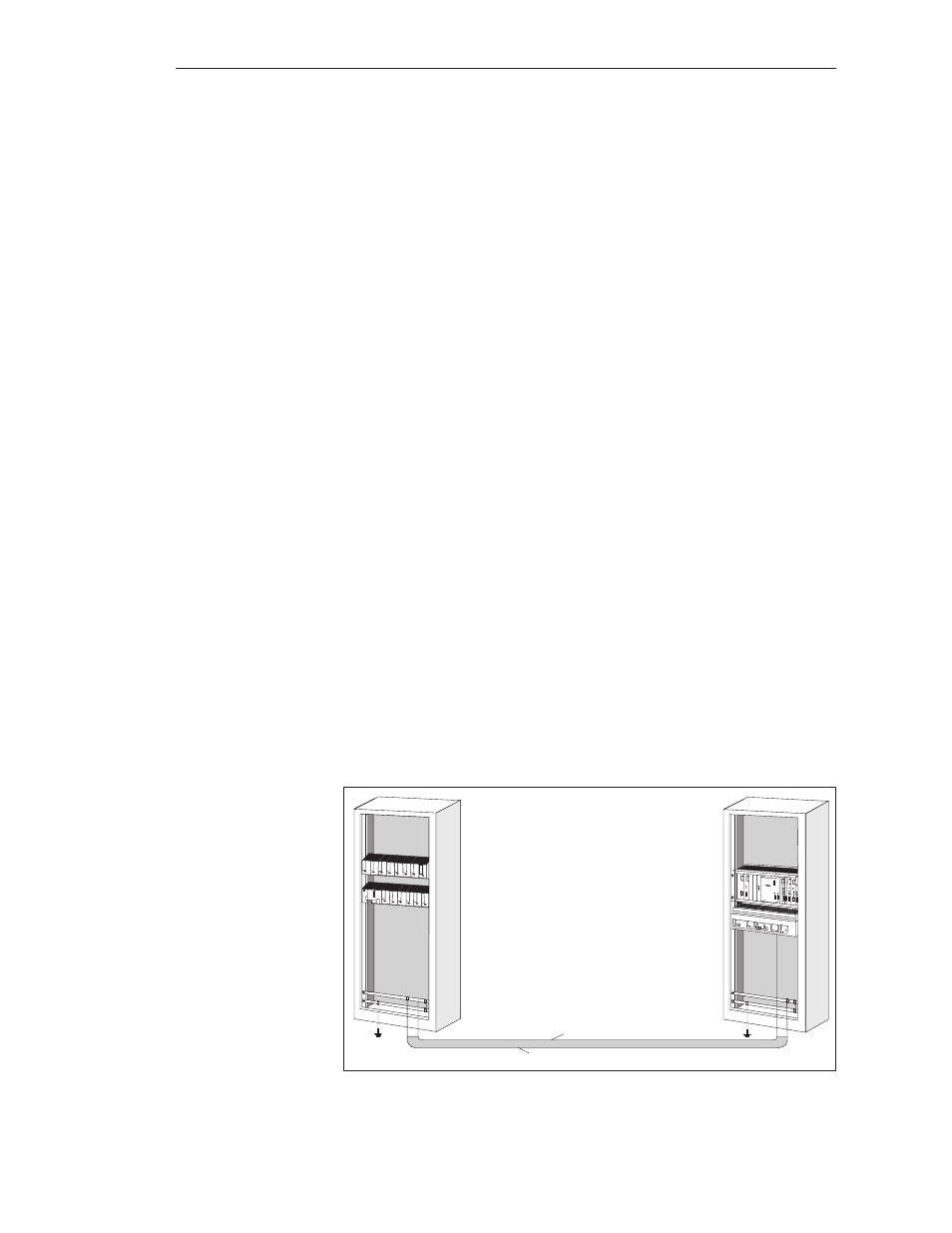

Equipotential Bonding Conductor

Signal Line

Figure 3-4

Routing of Equipotential Bonding Conductor and Signal Line

Installation Guidelines