0 dimensions and clearances, 1 clearances, Minimum clearances from combustible material – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 7: Recommended service clearances by model and size

Form I-PDH/SDH/PEH/SHH/PXH, Page 7

Other Field-Installed Accessories

4.1 Clearances

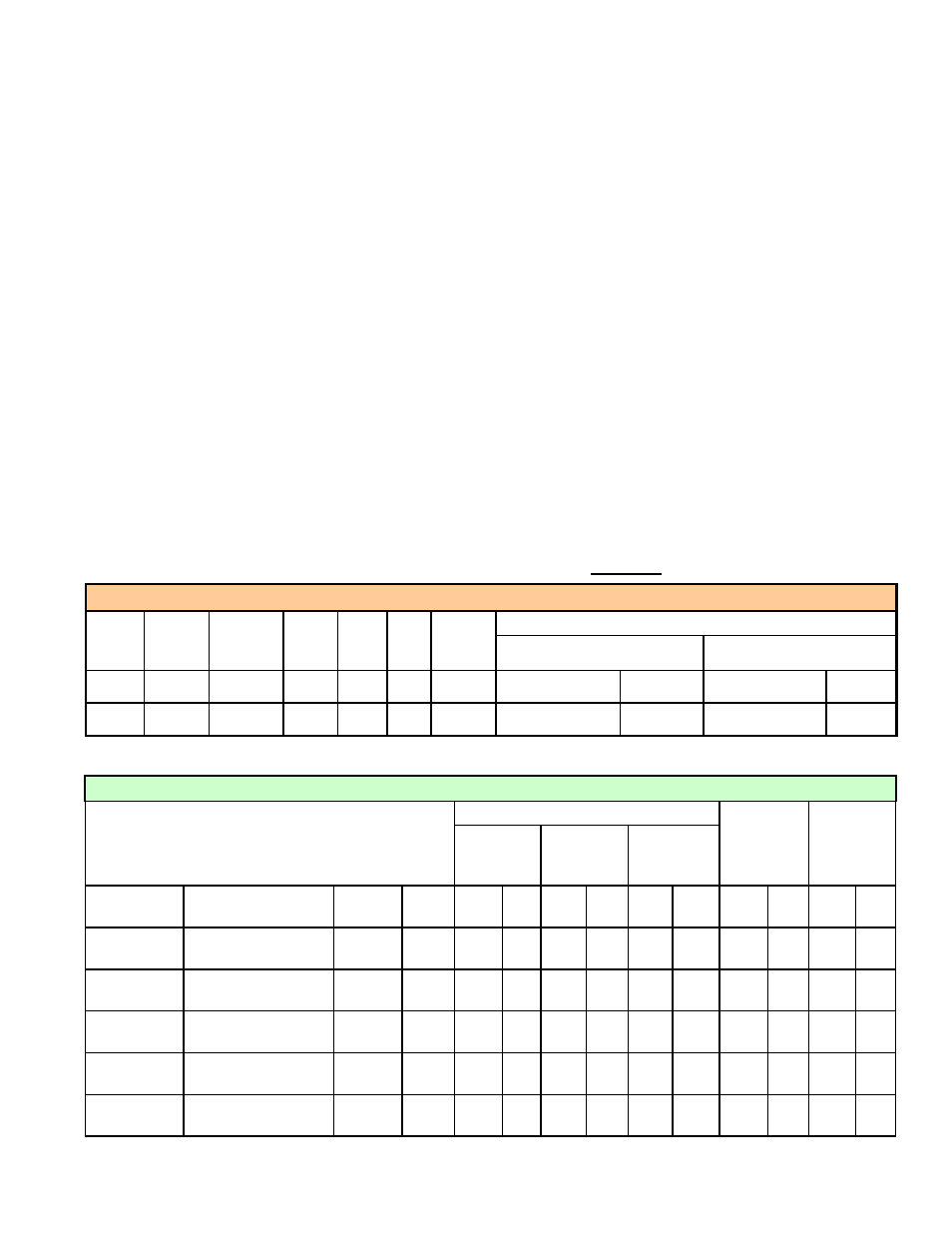

For safety and convenience, provide clearances as shown in

TABLE 2 and TABLE 3.

Clearance to combustibles is defined as the minimum distance from the heater to a

surface or object that is necessary to ensure that a surface temperature of 90°F above

the surrounding ambient temperature is not exceeded. Minimum clearances are also

listed on the heater rating plate.

Minimum Clearances from Combustible Material

Control

Side

Opposite

Control

Side

Front Rear Top Bottom

Gas-Fired Models

Vent Connector at Unit

Vent Pipe

inches

20

6

48

18

6

0

PDH/SDH - 18

SHH - 6

PDH/SDH - 6

SHH - 0

mm

508

152

1219

457

152

0

PDH/SDH - 457 SHH - 152 PDH/SDH -152 SHH - 0

TABLE 2 - Minimum Clearance from Combustibles - applies to All Sizes

Recommended Service Clearances by Model and Size

Model and Size

Control Side

Side

Opposite

Controls

Top

Control Side

(Basic)

Control Side

with Mixing

Box

Control Side

with Cooling

Coil*

SDH and PDH

PEH

SHH

PXH

inches mm inches mm inches mm

inches mm inches mm

75, 100

10A, 20A, 40A

N/A

000A

30

762

30

762

42

1067

6

152

18

457

125, 150

15B, 30B, 60B

N/A

000B

34

864

34

864

52

1321

6

152

18

457

175, 200, 225

N/A

130, 180 000C

30

762

30

762

42

1067

6

152

24

610

250, 300

30D, 60D, 90D, 120D

260

000D

42

1067 42

1067

58

1473

6

152

24

610

350, 400A

40E, 80E, 120E

350

000E

52

1321 52

1321

66

1676

6

152

24

610

TABLE 3 - Service Clearances

4.0 Dimensions

and Clearances

Storage and Startup

If this system is going to be stored, take precautions to prevent condensate formation

inside the electrical compartments and motors. To prevent damage to the unit, do not

store sitting on the ground.

After the system has been moved to its installation site, remove all of the shipping

brackets and check all of the fans for free movement. See the check lists in Paragraph

9.0 before starting the unit and completing the Startup Form.

* Clearance is required to remove slide out drain pan.

If your unit was ordered with Option UV2, UVC lights in the cooling coil module, the

bulbs and a box of parts are shipped in the blower compartment for field installation.

Being careful not to touch the bulbs, verify the components with the instruction sheet

included with the parts.

Before beginning installation, be sure that all shipped-separate options ordered are

available at the site. In addition to the vent/combustion air kit, field-installed, shipped-

separate options could include an energy recovery unit, a downturn nozzle, VFD, a

thermostat or other wall-mounted control, a remote console, a disconnect switch, fill

and drain kit, water hammer arrestor, firestat, a vent cap, and/or a smoke detector.