3 combustion air requirements - model pdh – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 21

Form I-PDH/SDH/PEH/SHH/PXH, Page 21

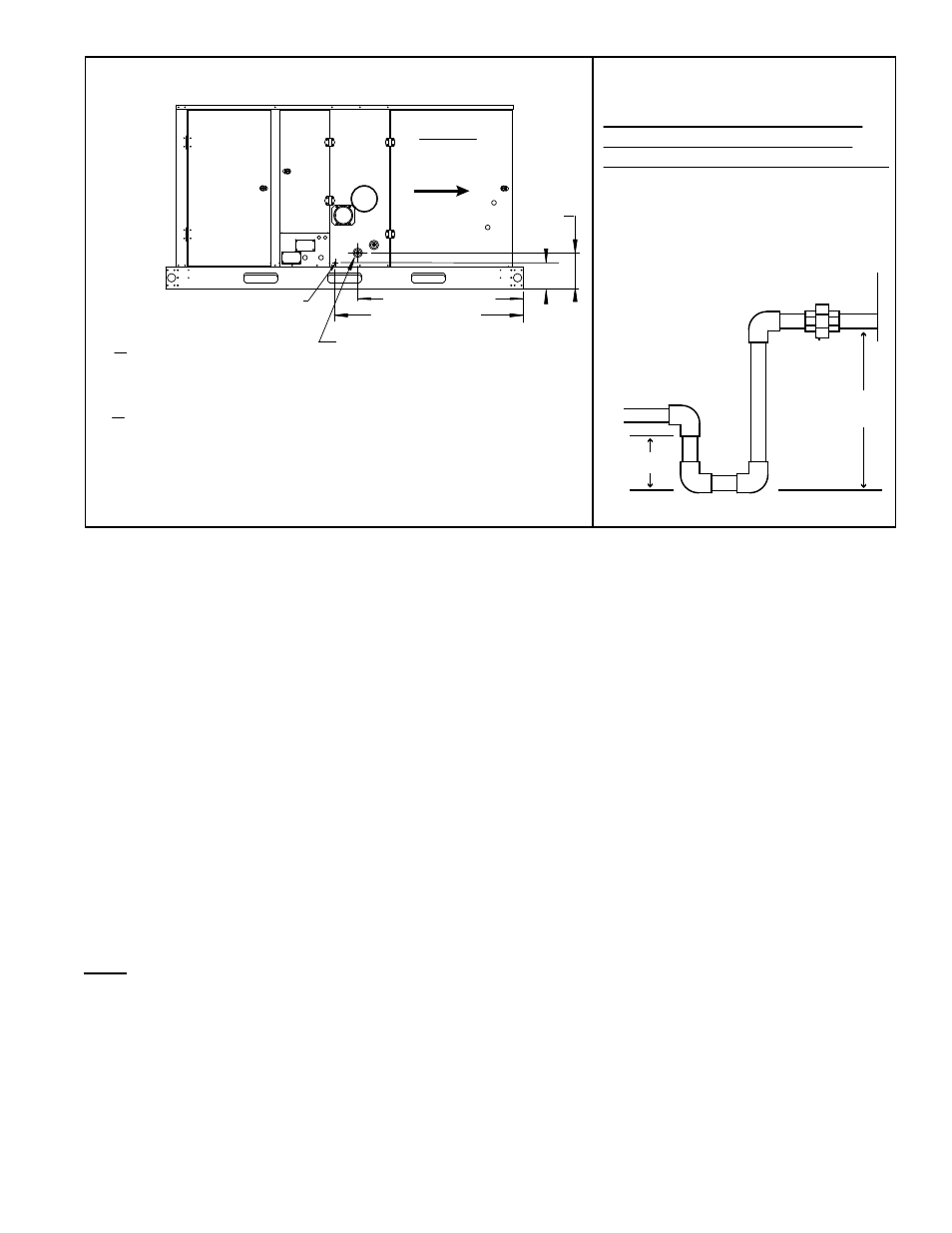

FIGURE 12 - Location of Condensate Drain Connections on a

Model SHH heat section

Minimum Dimensions for Secondary

Heat Exchanger Condensate Drain

Trap Required on all Model SHH Heaters

“A” = 3 inches (76mm) minimum

“B” = “A” plus at least 5 inches

(127mm)

Use 1/2” PVC pipe or larger

for condensate drain.

Drain Trap

Continue into

sanitary drain.

“A”

“B”

39-1/2” (1003mm)

44-5/8” (1133mm)

Secondary Heat Exchanger

Condensate Drain with 1/2” PVC

connection on all Model SHH units -

All Model SHH units require a

condensate drain with a trap as

illustrated in

FIGURE 13.

Burner Condensate Drain

with 1/2” NPT connection

on all Model SHH heaters

-- IF the system includes a cooling

module, Option AU, install a

drain line with a trap as

illustrated in

FIGURE 11.

-- IF the system does not include a

cooling module, cap this connection.

Side View

Model SHH

Airflow

8-13/16”

(224mm)

6-7/8”

(175mm)

FIGURE 13 - Secondary Heat

Exchanger Drain Trap - Model SHH

NOTES: See Vent Manual, Form I-SHH-V, for detailed information on

installing the vent pipe condensate drain.

If the system includes a cooling coil cabinet, the cooling coil cabinet also

requires a condensate drain. See Paragraph 6.6.3

Condensate Drain

Traps

A condensate drain trap is required for

each condensate drain line.

•

FIGURE 11 illustrates the trap in the drain attached to the burner and lists the

minimum required leg dimensions for that trap.

•

FIGURE 13 illustrates the secondary heat exchanger drain trap and lists the

required length difference for the trap legs.

The most important part of fabricating and assembling the traps is the length of the

individual legs of the traps. If the difference in the lengths of the legs of the traps is not

as illustrated, it could prevent proper drainage of the condensate and possibly permit

vent gas to enter the building. (The length difference is also what provides a “water

seal” that prevents leakage of vent gas into the sanitary drain.) The two traps may be

drained into a common pipe that is connected to the sanitary drain.

The orientation of the piping is not critical and may be arranged to suit the installation.

Unions are recommended to permit maintenance of the drains and to facilitate service

of the heater. A union is shown in both of the traps and a third union is recommended

in the drain pipe. If pipe insulation or heat tapes are required to prevent freezing, use

should be in accordance with generally accepted plumbing practices.

NOTES:

If the system has a cooling

coil, the cooling coil

cabinet will also require

a condensate drain;

see Paragraph 6.6.3 for

requirements.

A Model SHH has a

condensate drain on the

vent pipe; see Form

I-SHH-V for details.

6.3 Combustion Air

Requirements -

Model PDH

A Model PDH heater must be supplied with the air that enters into the combustion

process and is then vented to the outdoors. Combustion air enters through the com-

bustion air opening on the side of the unit and comes from the equipment location.

Sufficient air must enter the equipment location to replace that exhausted through

the heater vent system. In the past, the infiltration of outside air assumed in heat loss

calculations (one air change per hour) was assumed to be sufficient. However, current

construction methods using more insulation, vapor barriers, tighter fitting and gasketed

doors and windows, weather-stripping, and/or mechanical exhaust fans may require

the introduction of outside air through wall openings or ducts.

The requirements for combustion and ventilation air depend upon whether the unit

is located in a confined or unconfined space. An “unconfined space” is defined as a

space whose volume is not less than 50 cubic feet per 1000 BTUH of the installed

appliance.

Under ALL conditions, enough air must be provided to ensure there will

not be a negative pressure condition within the equipment room or space.

NOTE: For both Model

SDH and SHH, combustion

air must be ducted from

outside through the vent/

combustion air terminal

kit shipped with the unit.

See the Venting Manual,

Form I-SDH-V or Form

I-SHH-V, for combustion air

requirements.