8 blowers, belts, and drives, 0 mechanical (cont’d) – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 42

Form I-PDH/SDH/PEH/SHH/PXH, Page 42

6.8.4 Optional

Variable Frequency

Drive (VFD)

6.8 Blowers, Belts,

and Drives

6.8.1 Belts and Belt Tension

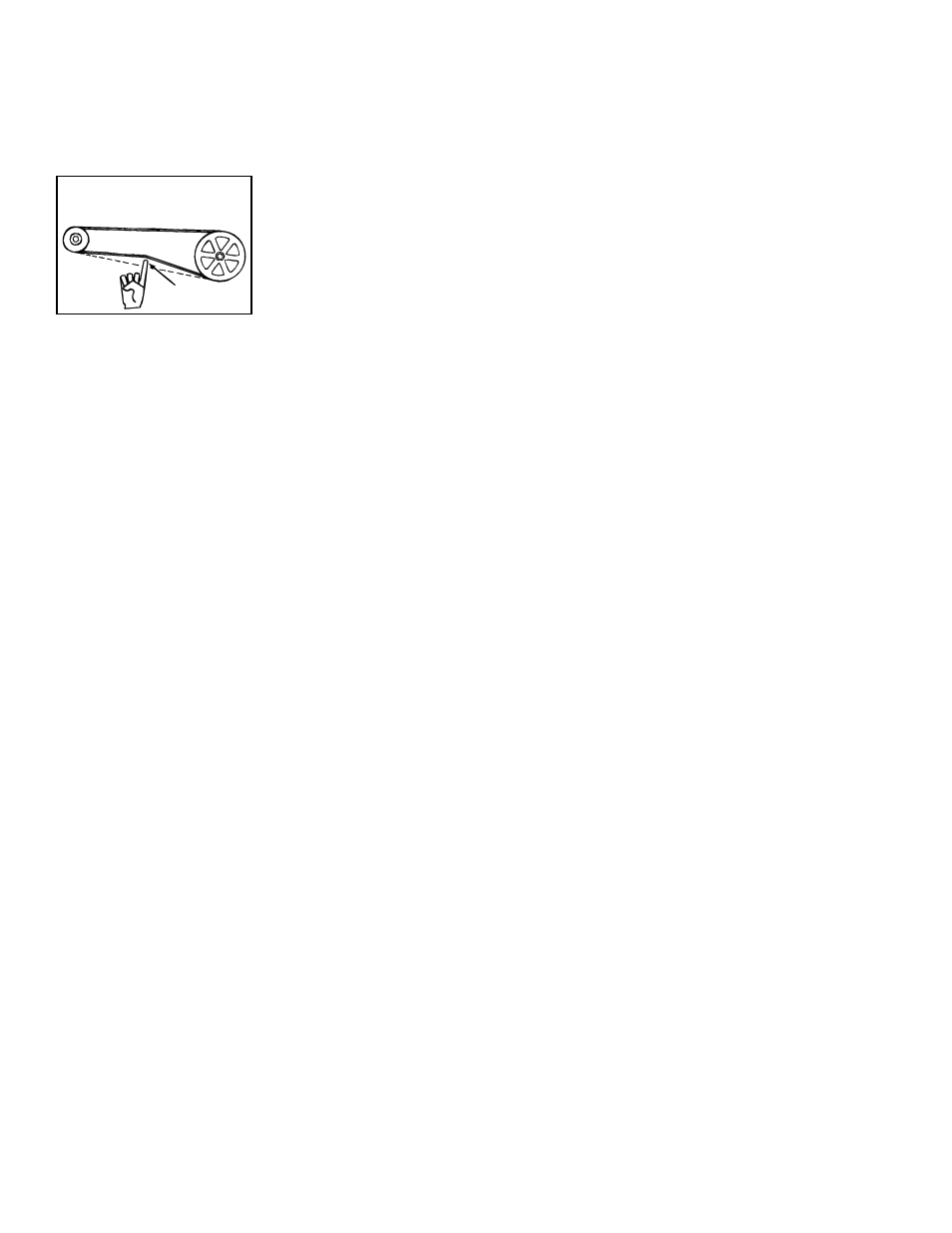

Check belt tension. Proper belt tension is important to the long life of the belt and

motor. A loose belt will cause wear and slippage. Too much tension will cause exces-

sive motor and blower bearing wear. Adjust the belt tension by turning the adjusting

screw on the motor base until the belt can be depressed 3/4” (19mm). (See

FIGURE

36.) After correct tension is achieved, re-tighten the locknut on the adjustment screw.

Be sure that the belt is aligned in pulleys.

3/4 (19mm)

FIGURE 36 - Check

Belt Tension

Linked Belts - If the belt needs tightening, the recommended method of tightening the

belt length is to count the number of links and remove one link for every 24. (A link is

made up of two joining sections of belt. For easier removal of links, turn the belt inside

out. But be sure to turn it back before installing. If belt is removed or replaced, be sure

to align directional arrows on the belt to the proper drive rotation.) After the first 24

hours of running at full load and at regular maintenance inspections, check the tension

of the belt. Be sure that the belt is aligned in the pulleys.

Solid Belts - Adjust the belt tension by turning the adjusting screw on the motor base

until the belt can be depressed 3/4” (19mm). (See

FIGURE 36.) After correct tension

is achieved, re-tighten the locknut on the adjustment screw. Be sure that the belt is

aligned in the pulleys.

6.0 Mechanical

(cont’d)

If ordered with a VFD, it may be either factory or field installed. If field-installed, follow

the manufacturer’s instructions and refer to the wiring diagram on the unit. Minimum

ambient temperature for a VFD is 18°F. Maximum distance from the unit is 50 feet.

When an optional VFD is ordered, the motor operates on two speeds as determined

by the electrical frequency. High speed is used for cooling and low speed for heating.

6.8.2 Adjusting

Blower Speed

The blower speed may be adjusted to achieve the desired outlet temperature, as long

as the adjustment is within the temperature rise and the static pressure limits shown

on the furnace rating plate. Motors are factory set between maximum and minimum

blower speeds.

If the duct resistance is low, the blower may deliver too high an air volume. If the resis-

tance is very low, the blower may deliver excess air to overload the motor, causing the

overload protector to cycle the motor. Reducing the blower speed will correct these

conditions. If ductwork is added to an installation, it may be necessary to increase the

blower speed. Decreasing blower speed will increase outlet temperature; increasing

blower speed will decrease outlet temperature.

At final adjustment, amperes should not exceed motor nameplate amp rating.

The installation must be adjusted to obtain a temperature rise within the range

specified on the furnace rating plate.

The belt drive on these units is equipped with an adjustable pulley which permits

adjustment of the blower speed. Follow these instructions to adjust the blower speed.

1. Turn off the gas (SDH/PDH/SHH) and the electric power (all models).

2. Loosen belt tension and remove the belt.

3. Loosen the set screw on the side of the pulley away from the motor.

4. To increase the blower speed, decreasing outlet temperature, turn the

adjustable half of the pulley inward.

To decrease the blower speed, increasing

the outlet temperature, turn the adjustable half of the pulley outward. One turn of

the pulley will change the speed 8-10%.

5. Tighten the set screw on the flat portion of the pulley shaft.

6. Replace the belt and adjust the belt tension. Adjust tension by turning the adjusting

screw on the motor base until the belt can be depressed 3/4”. (See

FIGURE 36.)

Re-tighten the lock nut on the adjusting screw. Be sure that the belts are aligned in

the pulley grooves properly and are not angled from pulley to pulley.

7. Turn on the power (PDH/SDH/PEH/SHH) and the gas (PDH/SDH/SHH). Set the

control to call for heat.

8. Check the motor amps with an ammeter. The maximum motor amp rating on the

motor nameplate must not be exceeded.

When service is complete, check for proper operation.

6.8.3 Blower Rotation

Rotation may be changed on single-phase motors by re-wiring in the motor terminal

box. Three-phase motors may be reversed by interchanging two wires on the 3-phase

supply connections.