Appendix, Startup form – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 67

Form I-PDH/SDH/PEH/SHH/PXH, Page 67

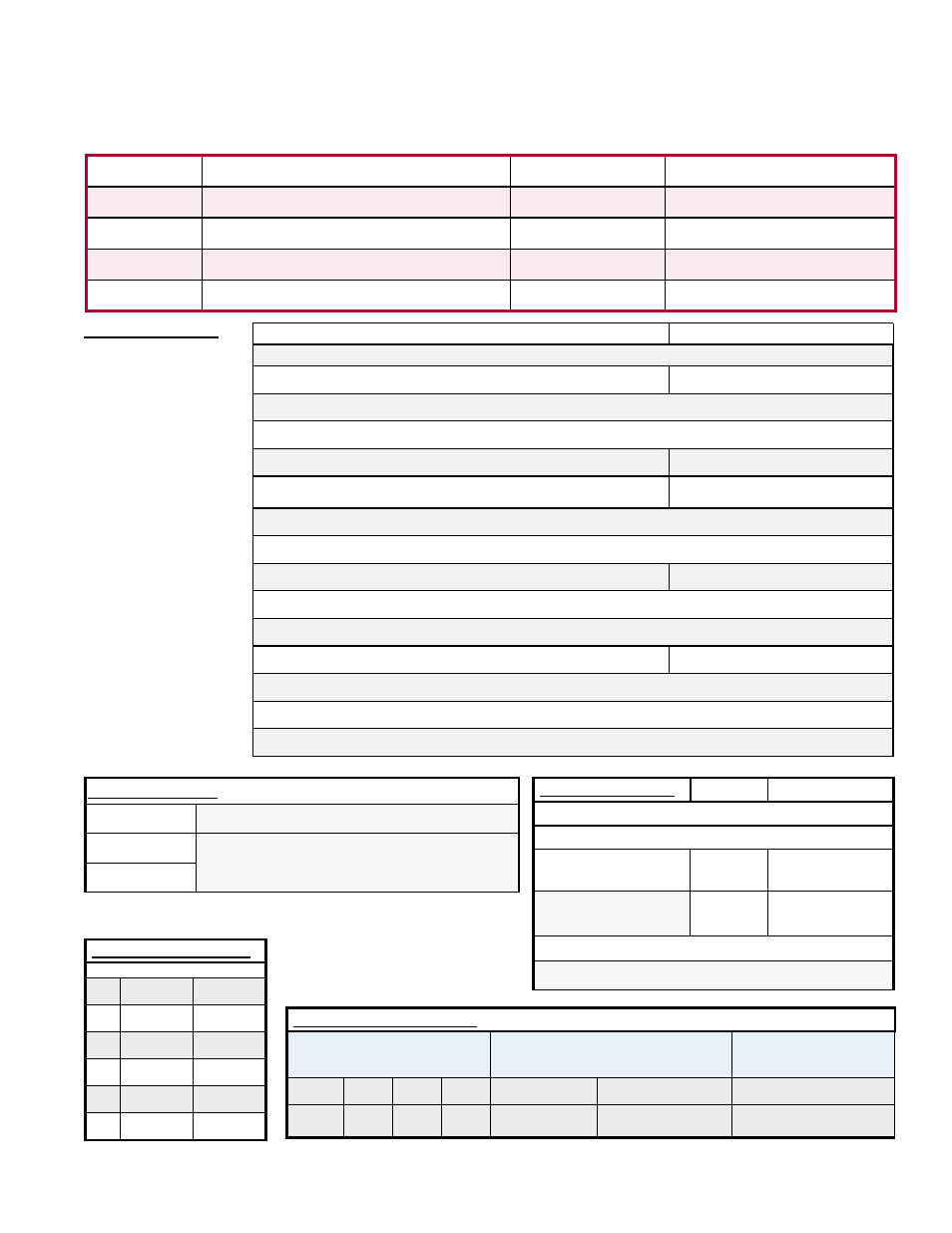

APPENDIX

Job Name:

Contractor Contact:

Street Address

Contractor Phone:

City, State, Zip

Model #

Date:

Serial #

Contractor:

Tag:

General Checks

Reference

NOTE: Checks may not apply depending on option selection.

□ Inspect unit for damage.

Paragraph 3.0

□ Verify shipping brackets are removed.

□ Check fuses/breakers for correct sizing. (Check rating plate for electrical requirements.)

□ Check clearances.

Paragraph 4.1

□ Check condensate connections. Fill traps.

Paragraphs 6.2 & 6.6

□ Verify air filters are installed.

□ Inspect dampers.

□ Tighten all screws on pulleys and fans.

Paragraph 6.8

□ Check and tighten all electrical terminals.

□ Seal electrical entrances.

□ Check optional dirty filter switch.

Paragraph 7.6.2

□ Check for manual resets (firestat, high gas pressure switch)

□ Verify all copper tubing is isolated and does not rub.

□ Verify crankcase heater (reheat compressor) is energized 24 hrs before startup.

Blower Assembly

□

Fan alignment Motor HP: ________ Name Plate Amps: ______

□

Belt tension

Motor Make/Amps: L1 L2 L3

______________ ______ ______ ______

□

VAV controls

Reheat Compressor Data

Outdoor Air Conditions:

Dry Bulb: _______________

Wet Bulb: __________

Circuit

L1

L2

L3

Name Plate RLA Head Pressure PSIG

Suction Pressure PSIG

Reheat

Gas Heating Section

□

LP

□

Natural Gas

□

Leak test gas piping

□

Purge air from lines

□

Check Inlet Gas

Pressure

Maximum: 14” w.c. for both

natural gas and LP

Actual Gas Inlet

Pressure: _________

Minimum: As listed on the

unit rating plate

□

Check Manifold Pressure (As listed on the rating plate.)

Actual Manifold Gas Pressure:____________

Electric Heating Section

Heater Number and Amps:

1

2

3

4

5

6

Start-Up Checklist

NOTE: See

Paragraph 9.0 for

a complete list.

STARTUP FORM

Fill out the applicable sections and keep for future reference.