0 mechanical (cont’d), 7 unit discharge (cont’d), 5 hot water heat module, option hw2 - pxh only – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

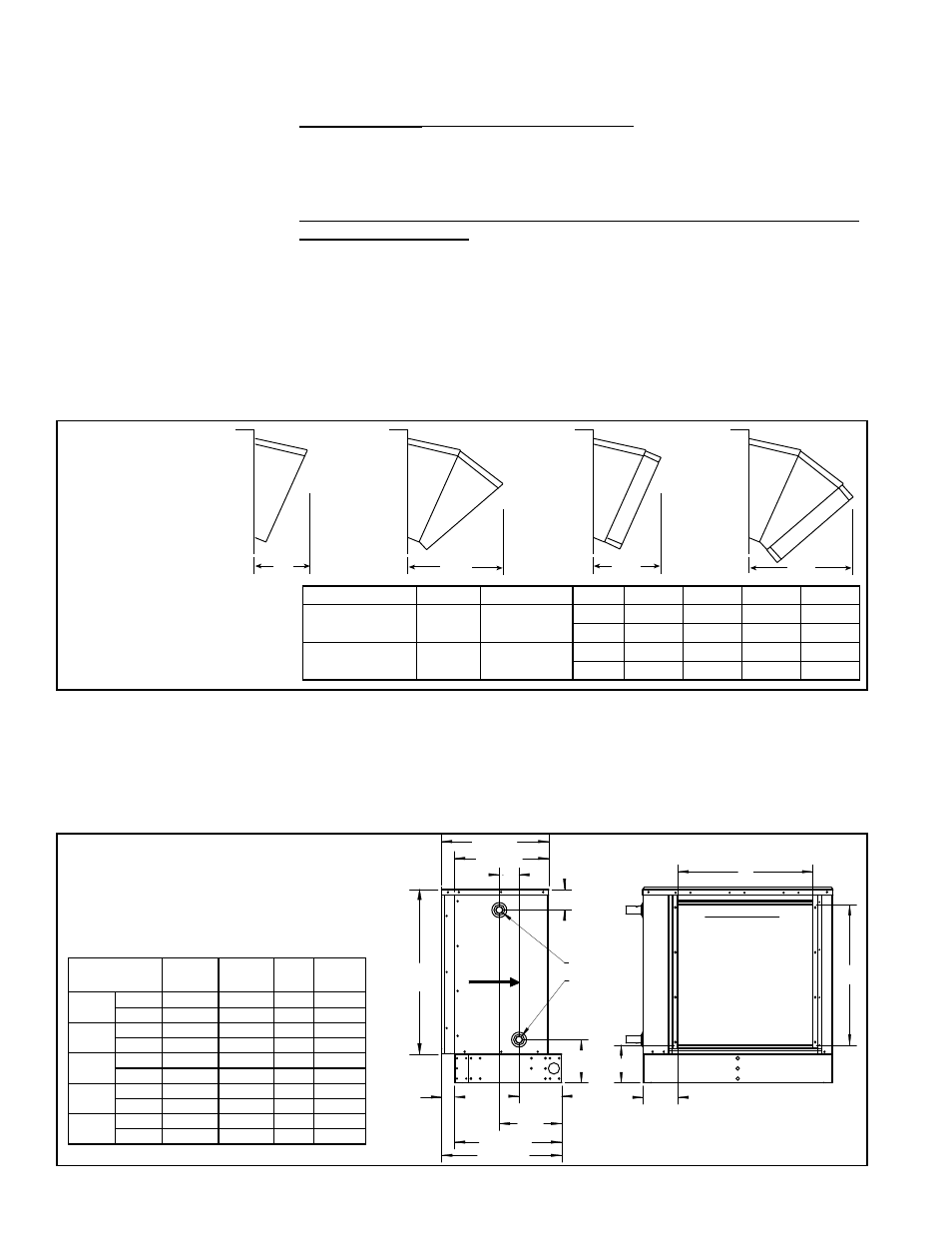

Page 40: Figure 34 - field- installed optional nozzles, Table 26a - dimensions

Form I-PDH/SDH/PEH/SHH/PXH, Page 40

6.7.4 Optional

Discharge Nozzles

with Horizontal

Louvers - Models

PDH, SDH, & SHH

Follow the illustrated instructions shipped with the option package to install

the nozzle options. Depending on which option was ordered, the nozzle will

have the downturn range shown in

FIGURE 34, with or without vertical louvers.

NOTES: Discharge nozzle options do not apply to electric heat Model PEH or to “no

heat” Model PXH. See Paragraph 6.7.5 for optional nozzles for Model PXH with hot

water heat.

FIGURE 34 -

Field-

Installed

Optional

Nozzles

Z

With 25-65°

downturn

nozzle with

horizontal

louvers

(Option

CD2)

With 50-90°

downturn

nozzle with

horizontal

louvers

(Option

CD3)

Z

Z

With 25-65°

downturn

nozzle with

horizontal

and vertical

louvers

(Option

CD4)

With 50-90°

downturn

nozzle with

horizontal

and vertical

louvers

(Option

CD5)

Z

TABLE 25 - Additional

Length of Optional

Discharge Nozzles,

Dimension Z (inches & mm)

PDH/SDH Sizes

SHH Size PXH (no heat) Option

CD2

CD3

CD4

CD5

75, 100, 125, 150

N/A

000A, 000B

inches

9

15-11/16

12-1/2

17-3/4

mm

229

398

318

481

175, 200, 225, 250,

300, 350, 400A

130, 180,

260, 350

000C, 000D,

000E

inches

13-9/16

23-5/8

17-1/8

25-11/16

mm

345

600

435

652

6.7.5 Hot Water Heat

Module, Option HW2 -

PXH only

Airflow

19-1/8 (486)

16-3/4 (425)

3-1/2

(89)

A

Water Inlet

Water Outlet

7-11/16

(195)

2-5/16

(59)

7-9/16

(192)

11-1/8

(282)

19-1/8 (485)

21-3/8 (543)

6-3/4

(171)

6-1/4

(159)

D

C

B

Discharge Opening

(Standard opening;

with factory-installed Option

AX2, Horizontal Louvers,

Option AX3, Horizontal and

Vertical Louvers, or

Option AX4, Duct Flange;

or field-installed Option CD2

or CD3, Discharge Nozzles,

or Option CD3 or CD4,

Discharge Nozzles with

Horizontal and Vertical

Louvers

The optional hot water heat module is factory-installed on the unit base at the dis-

charge end of a Model PXH. The module was either ordered with a factory-installed

coil or the coil is field-supplied for installation at the job site.

Dimensions

FIGURE 35A - Dimensions

of Hot Water Heat Module,

Option HW2 - inches (mm)

The cabinet height and width are the same as the PXH; see Paragraph 4.2. See

FIG-

URE 35A for length and connection dimensions. Add the length of the module to the

PXH length in Paragraph 4.2.

PXH with HW2

A

B

C

D

000A

inches 29-3/8

3-3/4

25

24

mm

746

95

635

610

000B

inches 29-3/8

3-3/4

25

34

mm

746

95

635

864

000C

inches 35-9/16 2-15/16

35

24

mm

903

75

889

610

000D

inches 35-9/16 2-15/16

35

40-1/4

mm

903

75

889

1022

000E

inches 35-9/16 2-15/16

35

48-1/4

mm

903

75

889

1226

TABLE 26A - Dimensions

6.7.3 Discharge Air

Sensor for Makeup

Air Application

(cont’d)

6.7 Unit Discharge

(cont’d)

6.0 Mechanical

(cont’d)

3. The procedure for installing the sensor and attaching the holder depends on

whether the sensor is a capillary or an electrical sensor. Follow the instructions

that apply.

Capillary Sensor (Option AG2, AG3, and AG60) - Locate the sensor capillary

and run it out through the hole in the discharge panel of the heater. Remove the

knockout on the end of the box. Put the capillary through the hole and secure the

bulb to the clip in the holder. Attach the bracket to the box. Attach the bracket to

the front of the heater (

FIGURE 33).

Sensor with Wire (Options AG15, AG16, AG58, AG61, AG62, DG5, DG6, D12B,

D12C, D12F, and D12G) - Push the element into the clip in the holder. Determine

where the sensor wire should go through the box and remove the knockout at that

location. Attach a field-supplied cable connector to the box. Connect the sensor

wire. Attach the bracket to the box. Attach the bracket to the front of the heater.