3 cooling module condensate drain – Reznor SHH (Indoor PreevA) Unit Installation Manual User Manual

Page 35

Form I-PDH/SDH/PEH/SHH/PXH, Page 35

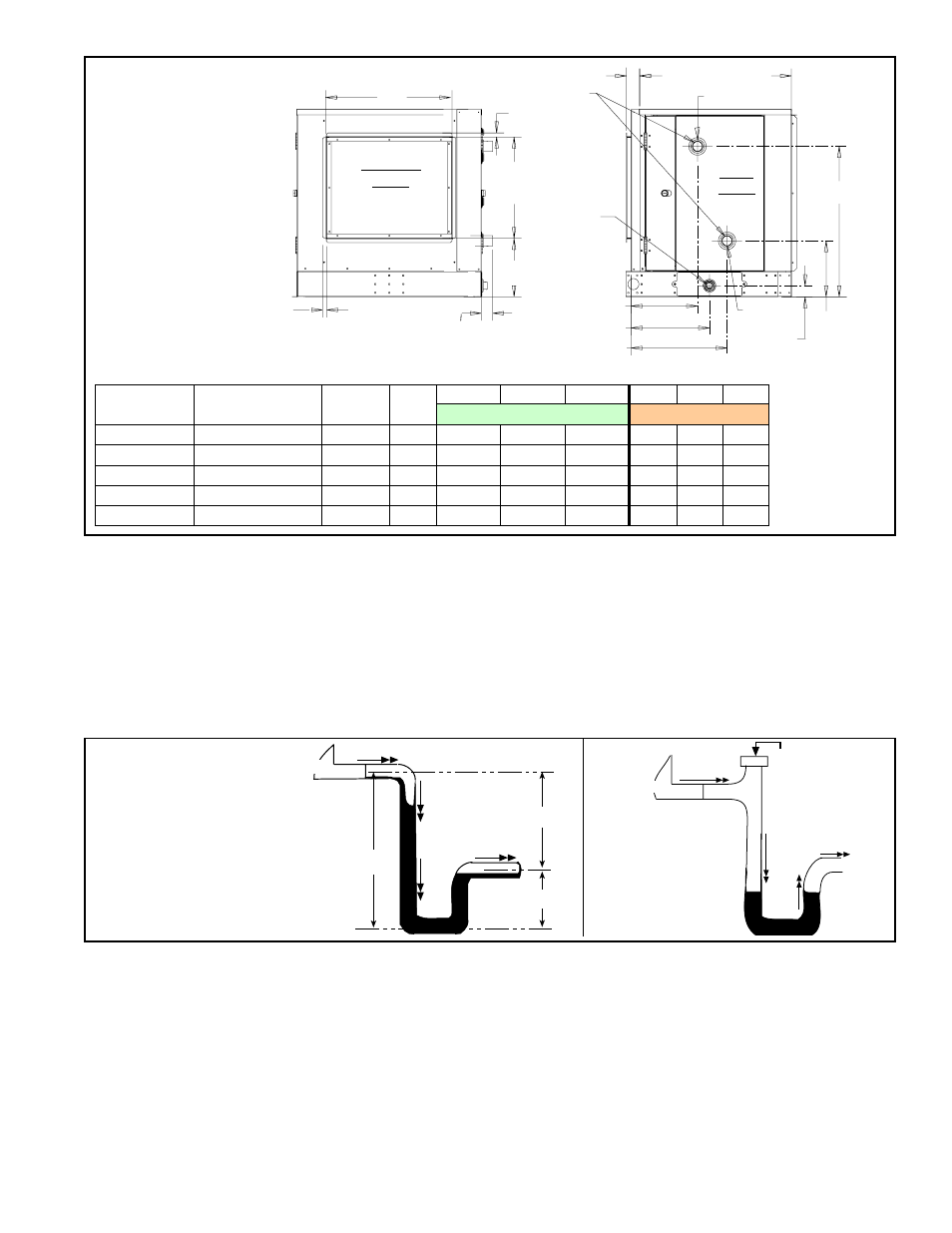

B

3/4 (19mm)

duct flange

3/4 (19mm)

duct flange

C

18-3/8

(467mm)

1 MPT

Drain

1-1/2 MPT

2-13/32(61mm)

1/4NPT Vent

27-3/4 (705mm)

D

1/4 NPT

Drain

2(51mm)

10-5/32

(2581mm)

12-21/64

(313mm)

14-21/64 (364mm)

17-47/64 (450mm)

Inlet Air

View

(with duct

flange*)

Side

View

3-3/32

(79mm)

NOTE: See

Paragraph

5.1, page 10,

for weights.

FIGURE 28 -

Chilled Water

Cooling

Coil Module

Dimensions

(no reheat)

Model PDH or

SDH

Model PEH

Model

SHH

Model

PXH

B

C

D

B

C

D

Dimensions (inches)

Dimensions (mm)

75, 100

10A/20A/40A

N/A

000A

22-7/8

10-19/32 27-9/32

581

269

693

125, 150

15B/30B/60B

N/A

000B

26-1/2

10-19/32 27-9/32

673

269

693

175, 200, 225 N/A

130, 180 000C

22-7/8

10-19/32 37-9/32

581

269

947

250, 300

30D/60D/90D/120D 260

000D

34-3/4

15-7/32

37-9/32

883

387

947

350, 400A

40E/80E/120E

350

000E

45-3/4

15-7/32

37-9/32

1162

387

947

TABLE 21 - Chilled Water Cooling Coil Module Dimensions

*If there is a mixing

box, the coil cabinet

will not have a duct

flange and this end

of the coil cabinet

will be attached to

the mixing box.

Drain Trap

To prevent air

from entering

always close

the cleanout.

Water Flow

Unit

FIGURE 29B -

Drain Trap with

Cleanout

B

A

A/2

C

L

C

L

C

L

Unit

Water Flow

Water Flow

A = 1” (25mm) for each 1”

(25mm) of maximum static

pressure plus 1” (25mm)

B = A + A/2

FIGURE 29A -

Condensate Drain

Trap Dimensions

6.6.3 Cooling Module

Condensate Drain

A removable drain pan with a 1” MPT drain connection is located below the coil cabinet

(See

FIGURE 27A or B or FIGURE 28). When connecting the drain line, provide a

means of disconnecting the line at or near the cabinet connection to allow the drain

pan to be removed for cleaning.

Ensure the system is level and

install a trap in the drain (see FIGURE 29A). Pitch the

drain line at least 1/2” (13mm) for every 10 feet (3M) of horizontal run. Drain lines must

not interfere with drain pan or access panels. An obstruction in the drain or a poorly

designed drain can cause the condensate pan to over flow which could result in unit

or building damage.

If the installation or local code requires, run drain into a waste water system.

The design of the drain trap is important. Since the condensate drain pan is on the

blower inlet side, there is a negative pressure at the drain relative to the ambient. The

trap height must account for this static pressure difference. Maximum negative static

can be determined by reading the negative pressure at the blower inlet and adding .2”

w.c. to allow for dirty filters.

If dimension “B” is not tall enough, the water seal will not hold and air will be drawn

through the drain pipe into the system. If the outlet leg of the trap is too tall, water will

back up into the drain pan. As condensate forms during normal operation, the water

level in the trap rises until there is a constant outflow.

FIGURE 29A illustrates the

appropriate dimensions for trapping a negative pressure system.

Improper trap design accounts for some condensate drainage system failures, but

incorrect use and maintenance of condensate drain traps can also cause problems.